A complete solutions provider

For every problem there is a solution. Working hand in hand with its customers, GF Machining Solutions’ aerospace segment manager, Alejandro de Quero Cordero reveals how relationships form a key pillar of the company.

GF Machining Solutions provides value-added manufacturing solutions for engine, aerostructure, equipment systems and avionic companies. These comprise dedicated solutions for blisks, discs, vanes and laser cooling hole drilling. Thanks to the premium expertise provided by Liechti and the Turbine Group, GF Machining Solutions develops manufacturing processes in partnership with aerospace OEMs and leading aerospace R&D centres. This December, the company will launch a new Liechti TurboMill 500 g machine dedicated to blade manufacturing.

Q) What are the types of performance demands placed on you by your customers?

GF Machining Solutions has a dedicated sales structure, the Turbine Group. This structure is focused regionally and provides not only sales support, but also application engineering, project management and customer services. Aerospace companies typically demand a ‘one point contact’ which is capable of managing the relationship with them as a key account manager.

Q) What kinds of productivity benefits do your customers enjoy from the successful implementation and use of your CNC machine tools?

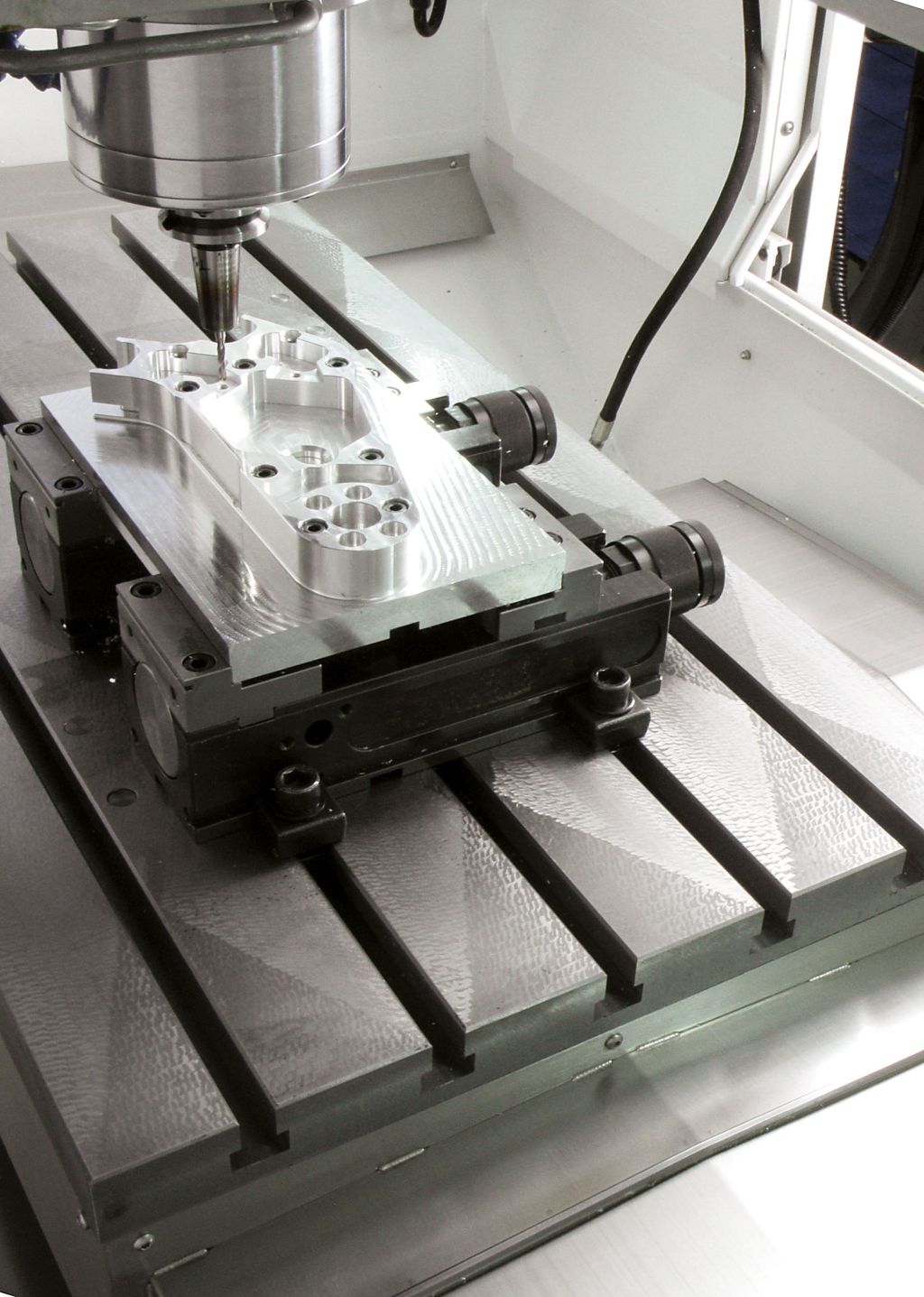

The productivity benefits and synergies that our customers enjoy can be summarised as following: fast, accurate chip removal and improved material removal rates (MRR) achieved through our high dynamic 5-axis milling technology with no thermal or mechanical material distortion.

Q) Do you have any thoughts on additive manufacturing and do you plan to launch your own machine tools?

GF Machining Solutions strongly believes that metal AM will actively support the aerospace industry, especially for the manufacturing of turbine components in nickel alloys and satellite components in aluminium. That is the reason why we have developed strategic partnerships allowing us to integrate metal AM printers into our machine portfolio. These latest perfectly match the needs of aerospace and energy companies, especially when it comes to the building process of large metal AM parts. Our DMP Factory 500 is capable of printing a volume of 500 x 500 x 500mm with titanium, nickel alloys, aluminium, etc.

Q) How much importance do you place on Industry 4.0 and the advent of ‘smart tools’ in general?

This is a key driver for GF Machining Solutions. As a solution provider, we are moving forward in the digital transformation to provide the possibility to our customers to make different technologies interact and this works inherently with the Industry 4.0 concept. In the last few years, GF Machining Solutions has developed a Digital Transformation team which focuses on machine communication, future AI functionalities and cloud computing solutions. Everything starting within the frame of Open Platform Communications Unified Architecture (OPC UA) connectivity.

Q) What do you feel are the most important assets of a company?

GF Machining Solutions' biggest asset is our employees. We have three core values: Learning, Caring and Performance. Each one of the employees - from service engineers to salespeople – is inspired by these core values.

Q) What differentiates your company from the competition and why should a customer use you over your nearest rival?

GF Machining Solutions is perceived as a company that works hand-in-hand with the customer - especially in the field of aerospace - by providing solutions from the first drawing until the machine is installed and beyond. We are the one and only complete solution provider by having an incomparable machine technology portfolio in-house: EDM, milling, laser texturing, laser micromachining and additive manufacturing - while providing automation, digitalisation and customer services.

Q) What aspects have helped your company get through the pandemic?

Like the rest of the companies with presence in the aerospace sector, GF Machining Solutions was hit hard. However, our installed base is mainly concerned with engine OEM companies and their suppliers. This has been challenging, but has also had some positive aspects. On the one hand, the supply chain suffered a lot and had to undergo an important restructuring process. Obviously, this didn’t help the machine tool business. On the other hand, our close relationship with OEMs allowed us to be closer to market leaders and being ready for the ramp-up phase in the industry, which we expect to see in 2023.

Q) Was the pandemic-enforced downtime a good time to effectively ‘reset’ and look at how efficiently you run your business?

During this period, GF Machining Solutions profited to underline its efforts on R&D projects. This was in response to what the major aerospace companies were doing: taking the opportunity of this 'reset' to ‘think out of the box’. Most companies took this as a ‘new approach’ period, where typical manufacturing technologies were challenged by three main criteria: cost reduction, performance improvement through automation and digitalisation, and adoption of ‘non-conventional’ manufacturing methods. In fact, during the Covid phase, GF Machining Solutions has seen increasing interest in technologies like EDM, Laser and Additive Manufacturing.

Q) What kind of industry landscape are we facing now that everything is back to normal?

After the Covid crisis, major companies are trying to reallocate some of the activities typically outsourced to different regions back to their original operational regions. This is creating an uneven project landscape where not all the suppliers are finding the financial support from OEMs to launch these projects.

In addition, the evolving and complex geopolitical and economic environment has forced these companies to perform a deep supply chain analysis. There are some doubts on ramp-up absorption by tier 1 and tier 2 companies. Despite the doubts, most people in the industry are confident about the aerospace industry’s resilience.

Q) Would you say that your long-standing partnerships have brought huge benefits, particularly as trusted relationships can lead to a better way forward for all?

Absolutely. OEM relationship is one of the key pillars of our company. Most of the R&D projects that we have developed in the past for our customers have had a strong input from aerospace OEM companies. Our relationship with them is based on a true partnership vision.

Q) What kinds of machine tool developments will we be seeing in the future?

Electrical chemical machining (ECM) is going to play a more important role in the manufacturing of aerospace parts. Nowadays, this is a complementary technology to EDM and milling processes, but in the future, it could substitute them completely for some specific applications. In this regard, GF Machining Solutions is improving the milling and EDM processes through data acquisition tools.

The technology that is already a reality is additive manufacturing (AM). The acceptance of the regulations and the ease of certification procedures is becoming a ‘normal standard’ in the industry. Trust in this technology is increasing and the trend is to produce bigger and more critical parts, while ensuring reliability of the process and quality of the parts through data analysis. GF MS is heavily investing in an in-situ monitoring system for its AM machines to ensure this. This might become a mandatory feature for the certification of aerospace parts made by AM.