Automation has just got smarter!

Intelligent automation and optimisation software solution specialists, Plataine reveals the best way to create an efficient manufacturing production schedule with Advanced Planning and Scheduling (APS) software.

Stockouts are frustrating. It leaves customers disgruntled and leads businesses to lose out on potential revenue. Overstocking leads to wastage instead. Add the complexities of brittle supply chains and the ever-changing business landscape, and you’ll realise how vital production planning and scheduling can be.

While production planning is nothing new, digital is undoubtedly changing its course and demands aerospace manufacturers to be more efficient with their processes. This article reveals why and how digital planning tools and manufacturing production scheduling software can help advanced manufacturers scale their manufacturing businesses amidst competitive rivalries.

Production planning is the process of allocating resources, raw materials, and activities to manufacture products for customers in a specified timeframe. Demand forecasting, inventory management, and job scheduling are all part of the planning process.

Production planning and scheduling allow manufacturers to design their manufacturing process efficiently by ensuring their production needs align with optimal resource usage. It also allows them to achieve production scheduling optimisation so that they can always fulfil orders without any delays or interruptions.

Automate to innovate

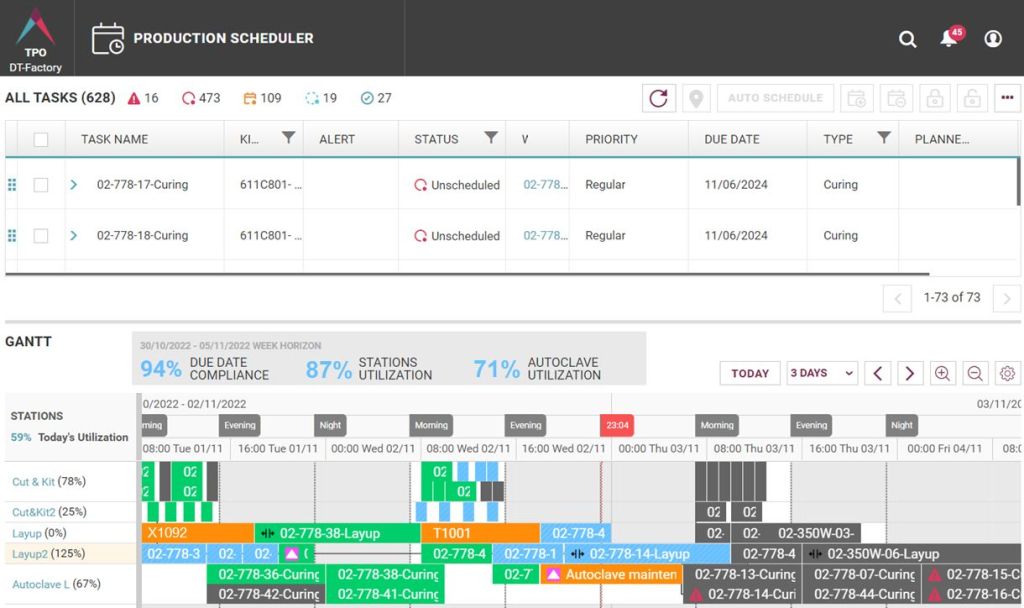

Production planning is automated software, allowing planners to make strategic decisions regarding their production by creating detailed schedules of activities on the factory floor. Accounting for raw materials, resources, and activities helps improve on-time deliveries and increase resource utilisation.

Why is manufacturing scheduling software important? Here are the top reasons why manufacturers should invest in production planning software:

Improved efficiency - optimal schedules and real-time data monitoring can help avoid potential delays and bottlenecks. Monitor shopfloor operations and be proactive about any issues to help increase efficiency and improve bottom lines. Moreover, such software can help adjust changes on the factory floor in real-time.

Enriched communication - often, the top floor and shopfloor in facilities are a distance away from one another. With manufacturing schedule software, distance is not a problem. These software solutions ensure all departmental staff, from manufacturing to sales and even HR, stay on the same page and exchange information instantaneously.

Improved customer relationships - always having the products on the shelves translates into happy customers. Moreover, standard procedures mean manufacturers improve their product quality and maintain it. As a result, their customer relationships tend to improve.

Material requirement planning - production planning software helps streamline business processes by striking the perfect balance between stockouts and overstocks. Through continuous updates of inventory in the software solution, automatic orders can be placed. Even better, these solutions can also update relevant personnel responsible for replenishments.

Efficiency guaranteed

An efficient manufacturing schedule ensures mapping all production steps, from demand forecasting to determining the resources needed. Here is how to create an efficient manufacturing production schedule:

Demand forecast - efficient manufacturing production scheduling starts with a well-grounded demand forecast. Manufacturers must estimate potential sales with reliability to optimise production. Most businesses don't have solid numbers on future sales but they can rely on market trends, historical information, and already-established orders to have a near-precision forecast. Analysis of the market, gathering information and scrutiny can help support demand forecast.

Maintain inventory control - the production pipeline needs a consistent source of inventory for production without interruptions. By having an inventory management plan in place shortage or waste during production should not be experienced.

Efficient inventory control involves reordering at pre-set reordering quantities, considering their storage conditions and lead-times. Shopfloor scheduling software can help take care of all this by implementing various inventory management functions and features.

Plan resources - the next major part of the production plan is resource planning. Taking into account all the minor resource planning details will save manufacturers unaccounted-for delays. An employee may get sick, or a machine may break down. Planning for these will ensure optimal utilisation of capacity.

Manufacturing and machine scheduling software covers all parts of the production process, and resource planning is no exception. Any change on the shopfloor is adjusted and accounted for through them.

Monitor production and standardise - if your manufacturing facility just began operations, monitor the production process and the average time it took to complete them. This process will help you process average production times for later productions. Compare your results to projections made and see where you stand.

With the right manufacturing production scheduling software, there is no need to do the calculations because they will do it for you. No human errors are an added plus.

Adapt and make adjustments - anything can happen on the factory floor despite long hours of planning. Accounting for the unexpected is just as important in planning as anything else. The key lies in adapting and being flexible, so the deliveries stay on track.

Lastly, manufacturers should reflect on the previous processes to assess what they could do better. Making adjustments is vital to continuous efficiency in production scheduling. Good planning software can help compare planned vs. actual production progress under a single software.

Everything on schedule

With so much emphasis on developing a good production schedule, the question is, why is it so essential to make one?

An excellent manufacturing production schedule ensures the manufacturer is in control of the manufacturing processes, allocating resources in stipulated periods in the most efficient manner. They will also be able to keep track of production schedules so that the products can reach their destinations on time.

Optimised manufacturing production schedules also ensure minimal production inefficiencies, resources are optimal, and unanticipated delays are adjusted. With such plans, manufacturers can ensure their manufacturing factory reaches optimal production capacities.

To sum up, a stable and optimised production schedule can be done more effectively with the best production planning tools. AI software solutions can help advanced manufacturers optimise their production levels and significantly reduce costs.