The data-driven factory

A look at how BAE Systems is developing next generation manufacturing capability for a next generation aircraft.

In 2020, BAE Systems opened the doors to a first-of-its-kind Industry 4.0 factory, home to a host of game-changing digital technologies set to advance manufacturing for the UK’s Tempest Future Combat Air System (FCAS) programme.

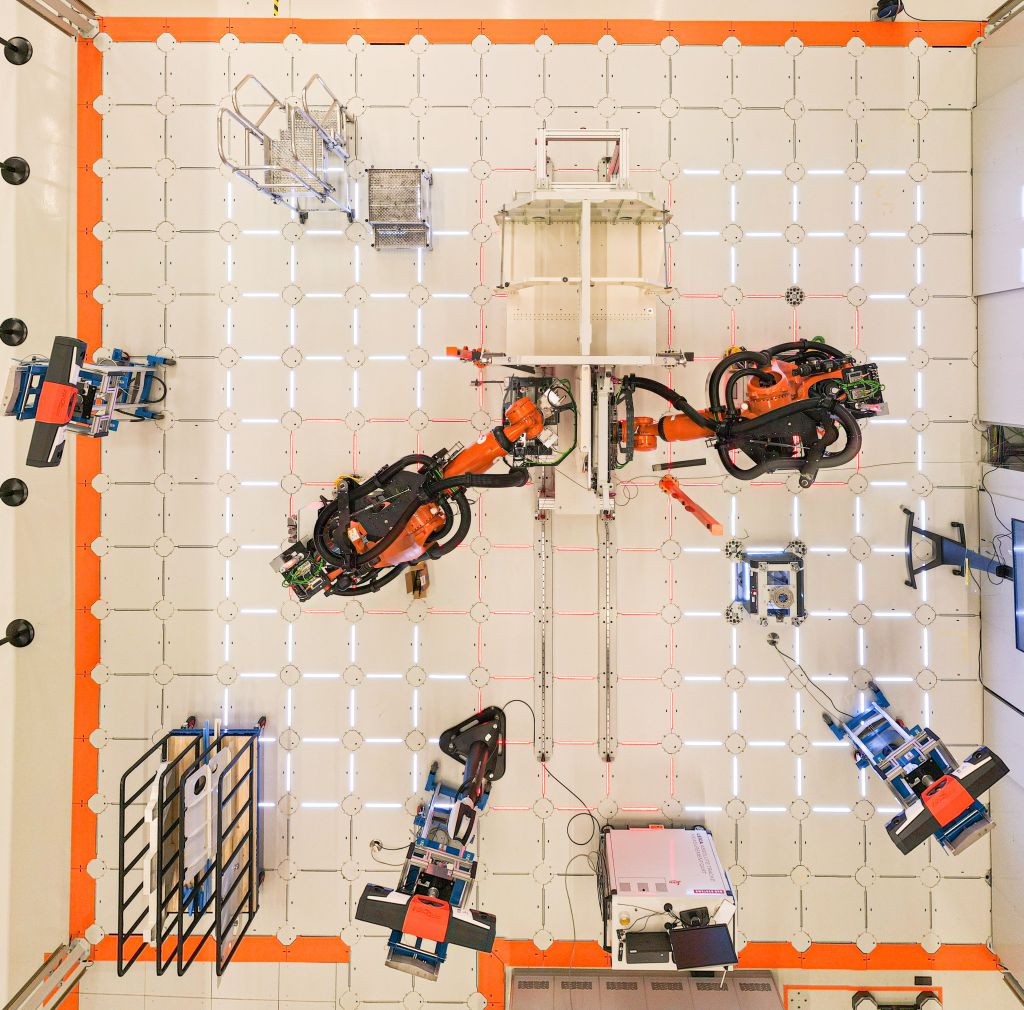

FCAS – with its drive to halve the timescales and significantly reduce cost for a future air system – demands a whole new approach to manufacturing. The factory demonstrates a new approach to the way humans and machines can operate together. Cobotic and flexible robotic technologies remove the need for heavy, fixed, long-lead tooling and can quickly switch from the manufacture of one item or platform to another. Intelligent machines and off-the-shelf robotic technology from the automotive industry have been modified to operate at the precise tolerances required for military aircraft. Such technology drives greater productivity by allowing operators to focus on more highly-skilled and strategic tasks and production managers to oversee operations from a fully digitised, virtual office.

Some of these technologies are already helping to drive efficiency into current production lines within the company, such as the Typhoon production line at Samlesbury where the Intelligent Workstation is in operation.

A model-based engineering approach has been adopted, where engineers use digital models and synthetic testing before any physical work takes place, saving significant time and money. By far the biggest enabler of the future factory environment is data engineering – the collection, collation, management and exploitation of data.

Really big data!

With FCAS, more data will be processed in a single year than constitutes every digital photo ever taken. The factory will deal in petabytes of data, from initial modelling through to shopfloor manufacturing.

“Our approach to designing the Future Combat Air System is not only about speed and efficiency; it’s a complete step-change in our approach to factories,” states Factory of the Future manager, Steve Wilcock. “This is revolutionary, digitally-enabled aircraft making that has major benefits across industry and beyond defence.”

Robotics in action on the factory floor

Following funding from the Department of Culture Media and Sport together with company funded investment, this is helping to further the development and testing of 5G enabled technologies around the factory. This ‘internet of things’ (IoT) approach is essential to deliver accurate data from partners into the hands of engineers, and to drive the robotic manufacturing technologies.

In the future, engineers within the factory envisage a world where the supply chain are collaborating and connected into BAE Systems through secure cloud environments, from tablet devices alongside aircraft in production. Data exploitation is a key area of focus to drive transformation right across the business. For example, how will we create a digital infrastructure to deliver a ‘single point of truth’ dataset, which can be shared on factory wireless devices utilising augmented and mixed reality? This is an area where BAE Systems are working with world-leading partners like Siemens, IBM and PTC and developing industrial IoT platforms for Factory of the Future connectivity.

Within the Factory there is already an operational robotic assembly capability for an aircraft’s front fuselage, which has been demonstrated physically (and virtually) to government and industry. The research and development that takes place within the Factory is also informing national UK Industry 4.0 manufacturing strategies, via the Made Smarter programme.

BAE Systems continues to work with over 50 partners across the UK to mature production standards and capabilities. These include SMEs, such as the aerospace automation specialist, ElectroImpact, who have helped to develop a highly reconfigurable, product-agnostic assembly capability that is in use today.