BBG supplies electric composite press to US aerospace company

BBG, the Mindelheim-based systems partner for the plastics processing industry, supplies an electric composite press for aircraft interior parts to a reputed aerospace company in the USA.

The cooperation between the two companies goes back to a project managed by the US subsidiary BBG North America. Composite prototype parts were produced for the aircraft manufacturer at the BBG technical centre at Oxford, Michigan. Convinced of the "made in Germany" production technology, the company ordered a pilot plant including the moulds for the production of lightweight components.

BBG can rely on decades of experience in the development and manufacturing of mould carrier systems and composite presses. Especially in the field of composites, hydraulic presses continue to be the standard today but the customer has intentionally chosen a system that is equipped with an electric drive. One of the main advantages is the high level of efficiency of the electric drive concept, which reduces energy consumption by around 35Wh per production cycle. Further benefits include particularly quiet operation and high dynamics, which contribute to shorter cycle times. Moreover, an electric drive is much easier to maintain than the hydraulic variant.

All systems are manufactured at Mindelheim, Germany and shipped worldwide from there. The current composite press is specifically configured for use in aircraft construction. The mould is manufactured by BBG North America and then shipped at the same time as the press.

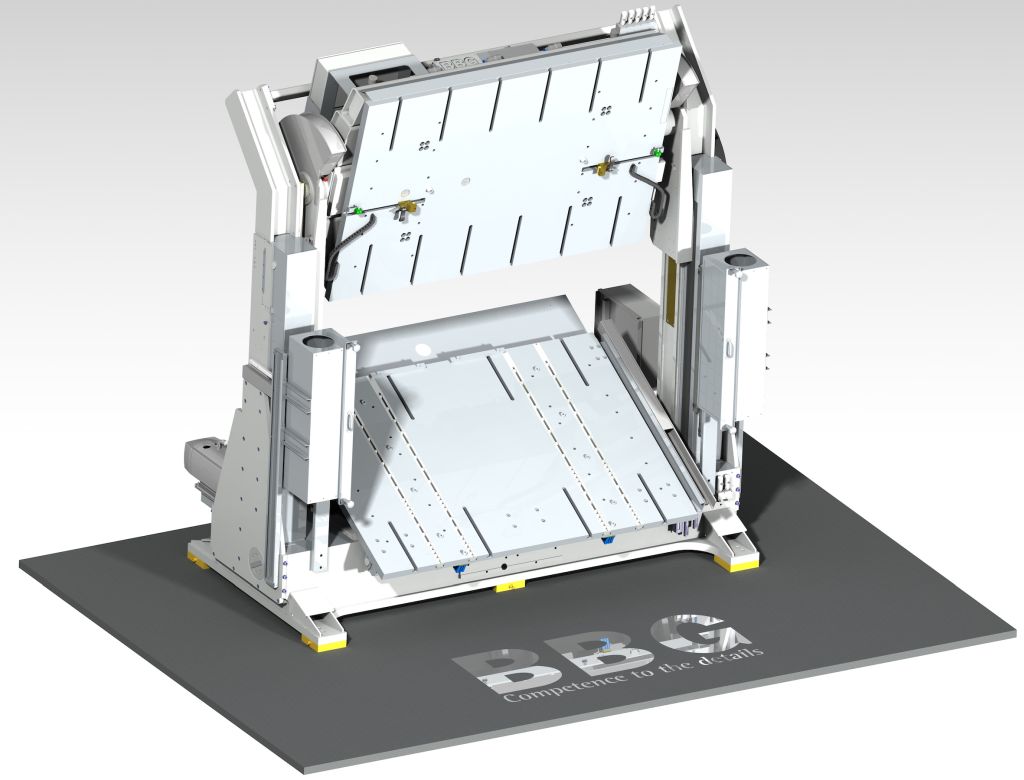

The mould mounting plates are 2,200 x 1,500mm, and moulds can be moved and positioned without any effort thanks to integrated pneumatic roller bars. The angle of traverse of the lower carrier plate is 0 to 27 degrees, and that of the upper plate is 0 to 75 degrees. This opens the press wide enough for operators to access the mould comfortably. Maximum capacity is 3,500kg for the lower plate, and 3,000kg for the upper plate.

Intelligent pressure control allows for a press force of 60 US tons - which corresponds to about 535kN – and an infinitely variable adjustment option from 50kN onwards.

The composite press is operated via the Easy Control 2.0 user interface developed by BBG itself. The man-machine interface simplifies the programming and operation of the press while increasing productivity and improving process reliability at the same time. For most of BBG's customers, this is a core concern: Just as in aircraft manufacturing, production must deliver reliable results while being simple and manageable. The user interface shows functions and workflows of the press and the mould, users can operate the machine quickly and easily without PLC knowledge.