Just right for aerospace!

Boeing South Carolina is home to the company’s second 787 Dreamliner final assembly and delivery facility. In a Q&A session with Aerospace Manufacturing, the South Carolina Department of Commerce explains how it supports Boeing’s supply chain by creating an environment that is just right!

Boeing South Carolina is home to the company’s second 787 Dreamliner final assembly and delivery facility. In a Q&A session with Aerospace Manufacturing, the South Carolina Department of Commerce explains how it supports Boeing’s supply chain by creating an environment that is just right!

Q) How important is it for a region like South Carolina to have an aerospace manufacturing giant like Boeing located within the state?

Since November 2009, when Boeing selected North Charleston, S.C. for a new 787 assembly and delivery facility, South Carolina’s aerospace industry has truly soared, taking the state and its economy to new heights. Since that time, aerospace-related firms have announced capital investments of $2.2 billion, bringing more than 9,000 new jobs to the state.

Today, there are more than 400 firms, employing 50,000 South Carolinians in the private sector component of the state’s aerospace cluster. If you consider South Carolina’s four military aviation facilities, as well as its private sector firms, aerospace has a total economic impact of more than $19bn on the state and supports approximately 100,000 jobs.

More than just providing a direct economic boost, however, Boeing’s arrival in South Carolina helped elevate the state’s brand as a global leader in advanced manufacturing. Adding to an already impressive roster of industry heavyweights, such as BMW and Michelin, Boeing’s decision to operate in South Carolina signalled to the world that complex, high-tech products could be made here. In the years following Boeing’s big announcement, globally-recognised firms, like Giti Tire, Mercedes-Benz Vans and Volvo Cars, have made significant investments in the state.

Q) What was it that originally brought Boeing to S.C.?

South Carolina’s top asset is its loyal, highly-skilled workforce. When examining the state, Boeing was able to look at what BMW and its associates had been able to accomplish since 1994. In just under 15 years (1994-2008), the German automaker had already been able to produce more than one million vehicles, expanding its facility numerous times.

Before BMW, there were very few automotive workers in South Carolina. Today, nearly 25 years later, there are approximately 66,000. State and community leaders were able to collaborate and develop that automotive workforce, showing that the same thing could be done in aerospace.

Q) What kind of support do you offer to both Boeing and its supply chain and is what you provide unique to the region?

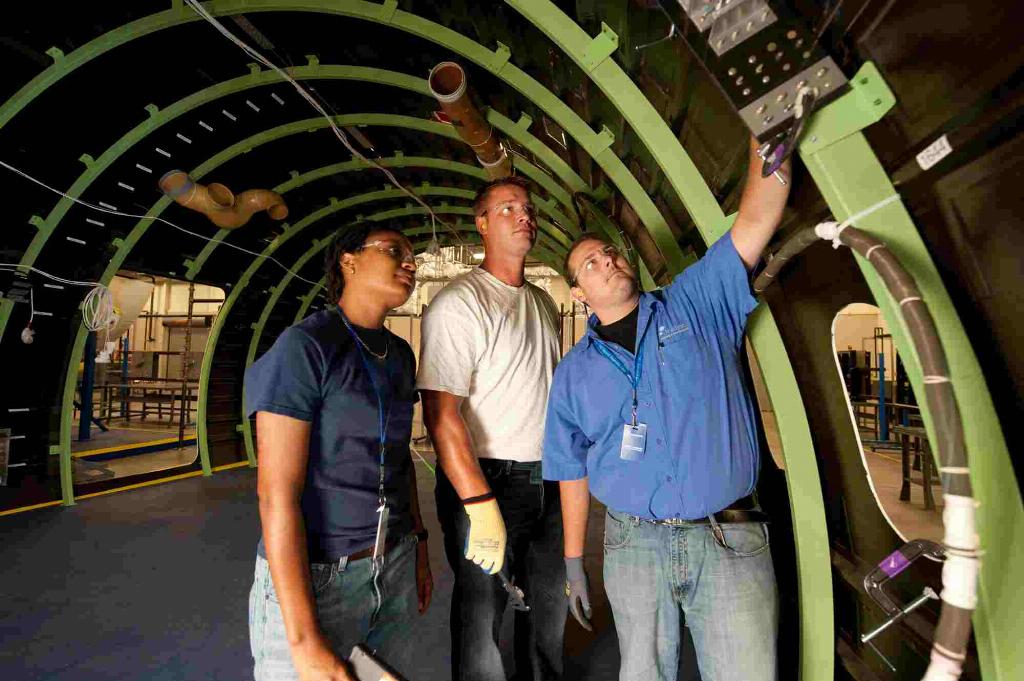

To ensure that South Carolina is cultivating a healthy pipeline of talented aerospace workers, several programmes and initiatives are utilised, including the world-renowned readySC. For more than five decades, readySC, which is administered by the S.C. Technical College System, has provided well-trained employees at no charge to qualifying companies that invest in the state. Serving more than 75 businesses in Fiscal Year 2016, the program trained nearly 4,000 individuals. ReadySC’s Boeing-specific curriculum comprises more than 170 courses taught by approximately 50 Boeing-qualified instructors.

In addition to workforce development, the State of South Carolina also assists aerospace companies by hosting B2B supplier matchmaker events. Aimed at providing the tier two, three and four suppliers with an opportunity to connect, one-on-one, with OEMs, these events are critical in the effort to grow South Carolina’s aerospace industry at all levels. At last year’s B2B supplier matchmaker, which was held in conjunction with the S.C. Aerospace Conference, seven different OEMs and more than 25 suppliers were in attendance.

Q) Can you say anything about the colleges and universities feeding into Boeing and how young people are being persuaded that engineering can be a satisfying and enjoyable career?

One of the biggest challenges industry leaders face is changing the stigma that exists regarding manufacturing. The manufacturing jobs in South Carolina, today, are much different than they were decades ago. They are clean; they are well-paying and, they are high-tech.

Among the initiatives used in South Carolina to encourage youth involvement in manufacturing are the state’s 12 Regional Workforce Advisors. Connecting business with education in specific regions across South Carolina, the advisors are focused on ensuring that the state’s local education offerings are aligned with the needs of both existing and future industry.

Another tool used is that of S.C. Future Makers, a public-private partnership that engages South Carolina's manufacturing and technology communities with middle and high school students, along with four-year college students. A joint effort between multiple state agencies, S.C. Future Makers is designed to fill any and all gaps in science, technology, engineering and math (STEM) skills in the state and set the stage for continued economic growth.

South Carolina’s institutions of higher education are also heavily involved in supporting the state’s aerospace industry. For example, the University of South Carolina established the McNAIR Center for Aerospace Innovation and Research in 2011. Located in Columbia, S.C., the Center is focused on aerospace-related education, research, K-12 STEM support, workforce development and industry engagement.

With a research team of more than 30 faculty in the mechanical, chemical, civil and electrical engineering fields, the Centre aims to advance the state's knowledge-based economy through aerospace research, interdisciplinary education, economic development, outreach and collaboration with aerospace and allied industries, as well as related government agencies. Boeing entered into a research partnership agreement with the McNair Centre that is helping develop the region’s technical expertise and ecosystem in advanced composite manufacturing.

The arrival of Boeing in 2009 did more than propel South Carolina’s aerospace sector, it also gave a boost to the state’s advanced materials industry. From plastics and optics to photonics and composite materials, South Carolina now supplies the world's manufacturers – including Boeing – with the items needed to make some of the planet’s most complex products.

Recent successes in this thriving sector include companies like Toray, which, in 2014, announced the construction of a $1bn carbon fibre facility, representing one of the largest initial capital investments in state history.

GKN Aerospace has also been a success story. The company opened a 150,000ft2 facility in Orangeburg County in August 2012. Initially, the operation was focused on the manufacture of fuselages for the Honda Aircraft Company, producing approximately four each month, but in 2013, GKN was selected to manufacture Boeing’s advanced-technology winglet for its 737 MAX single-aisle aircraft. Then, in June of 2015, the company announced plans to open an adjacent facility to produce inlet lip skins for the Boeing 737. The facility opened in 2016 is now in full production.

Q) How does the state intend to respond to Boeing’s demand signals for new and advanced technological innovations in the future?

Long ago, South Carolina was known as a state that exceled in the three T’s – textiles, tobacco and tourism. While strong textile and tourism industries still exist, advanced manufacturing has truly become a main driver of the economy. As such, a supporting high-tech sector has emerged. In fact, last year, South Carolina had the 11th highest tech employment growth rate in the United States.

With more than 200 new tech firms opening in the Palmetto State last year, South Carolina achieved a growth rate of 3.9%, doubling the national average. Only Oregon saw a larger jump. Adding to this state-wide success are communities, such as Charleston, S.C., which has been one of the fastest-growing technology areas based on gross domestic product over the past five years.

This continued innovation and tech economy growth will help support future technology demands in the advanced manufacturing industry. And, as the state and its industry leaders – like Boeing – seek to remain on the cutting edge, the continued development of this tech economy remains a priority.

Q) What are your hopes for the launch of the new 787-10?

In South Carolina, manufacturing is more than what we do; it’s who we are. The workers in this state make things with a lot of pride, and we’re proud that Boeing has selected its South Carolina operations to produce the new 787-10. We know that when a customer purchases a product made in a South Carolina facility – such as Boeing’s new 787-10 – they’re going to get something that was produced the right way.

This is evident by the state’s remarkable export growth in recent years. Since 2014, South Carolina has seen its export sales of aircraft, spacecraft and related parts increase by more than 300%. In 2016 alone, South Carolina exported approximately $5.7bn in aircraft.

In South Carolina, we’re big proponents of the team-first approach. It takes all of us working together to be successful. So, whether it be the 787-10 or any other product, we look forward to supporting Boeing and the entire aerospace industry as they both continue to grow in our state and around the world.