Fast fastener fixings!

Combining the advantages of threaded inserts with helicoils, Böllhoff’s precision thread insert for plastic components with screw-locking is helping engineers find solutions for weight reduction, short cycle times and self-locking fasteners.

Today, the world of lightweight construction can no longer be imagined without plastics, and they are conquering ever more sectors. Their great flexibility in terms of processing and component design leads to an increasing replacement of metallic materials by plastics. Due to their outstanding mechanical properties, low weight and attractive manufacturing costs, they are a fundamental part of industry today.

More and more, plastic components are used in the aerospace industry, and especially in aircraft interiors. Parts such as armrests, overhead compartments or even seats are completely or partly made of plastic and need to be assembled with the rest of the aircraft. Fasteners don’t always comply with the extremely strict requirements of the aerospace constraints and stresses. Moreover, it is sometimes hard to find the good assembly system which combines efficiency, robustness and standards when using different kinds of materials (metals, plastics, carbon fibre-reinforced plastics, etc.).

After moulding, thread inserts make it possible to achieve the advantageous synergy effects resulting from high-strength metals in combination with plastics. They have been specifically designed for this use and the result is excellent: a wear-free, high-strength thread in high-quality plastic components. The thread insert is heated to the melting temperature of the plastic. As a result of the heat transfer upon insertion, the plastic is plasticised for a short time and flows into the undercut of the thread insert. Upon cooling, a low-stress interference is realised. Böllhoff, one of the worldwide leaders in fastening and assembly technologies, has extended this innovative product family with a new variant: the HITSERT Screwlock.

Keeping a tight rein

This is a situation everyone knows. When under load, screw fixings tend to loosen. A flying aircraft is subjected to severe conditions and load, such as extreme vibration, alternating loads or kinetic energy being absorbed. In many applications it is absolutely necessary to take precautions against unintentional loosening.

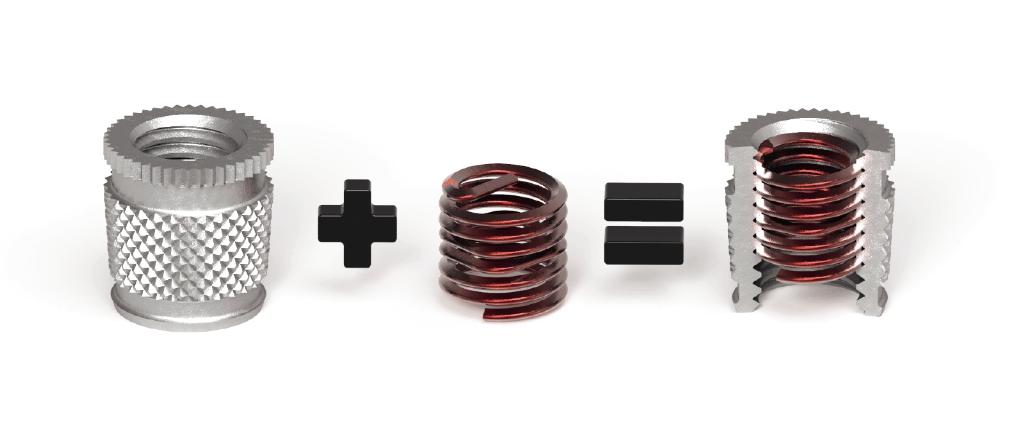

As a specialist, Böllhoff offers the HITSERT Screwlock for these applications. An efficient combination of two fasteners. Proven and reliable technology, the HITSERT Screwlock combines the advantages of an aluminium (EN AW 6061) HITSERT 2 and a stainless steel HELICOIL Screwlock thread insert. These two elements match perfectly to provide considerable benefits for screwed connections with high requirements. Locking of the screw is achieved with a polygonal-shaped thread of the HELICOIL Screwlock. These threads have a locking effect on the flanks of the screw or bolt to be screwed in. The result is an elastically-resilient frictional locking mechanism with the bolt or screw resisting self-loosening and unscrewing. This new fastener already complies with the aerospace standards NASM 8846 (for torque values) and NASM 25027 (for testload values).

Depending on the specific application, increased clamping torques can be achieved with several polygonal-shaped threads. The resulting clamping torques can be compared to the specifications in the list of standards DIN 267, Part 15, ISO 2320 or adapted to individual application.