CMMs come full circle

Aerospace Manufacturing hears how rotational innovation helps coordinate measuring machines work smarter.

Coordinate measuring machines (CMMs) play a vital part in precision engineering and quality control in the aerospace industry. Indeed, the global dimensional metrology market in the aerospace industry generated $482.9 million in 2012, with the CMM segment expected to grow at a compound annual growth rate of 4.0% by 2017 according to some commentators.

Driving the increased demand for high accuracy measurement is the industry wide requirement for fuel efficiency and lightweight engines, as well as environmental regulations requiring reductions in both noise and carbon emissions.

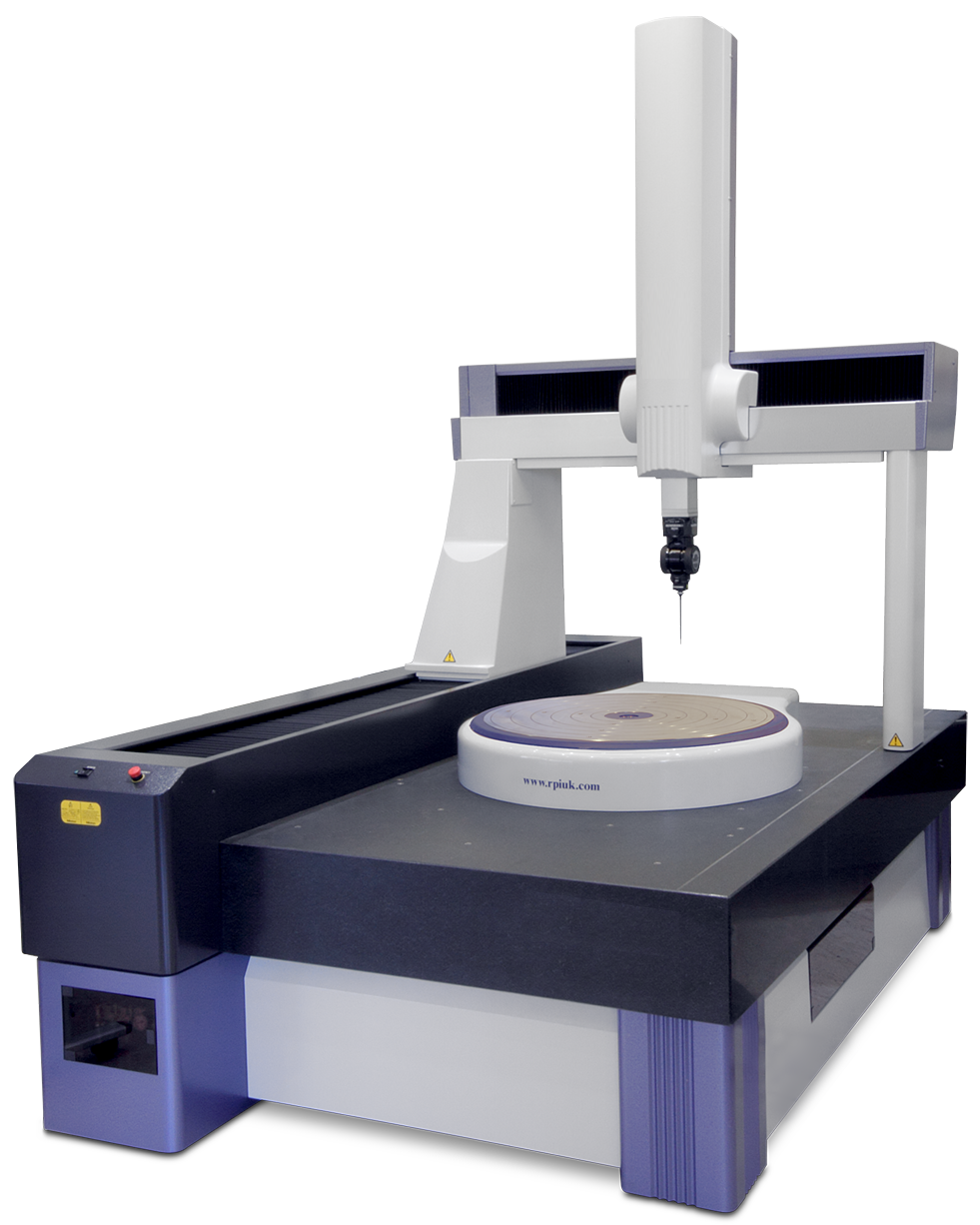

It’s no secret that all major aerospace manufacturers use CMM machines, sometimes as intensely as 16 hours a day, to measure the physical geometrical characteristics of aerospace components. But what is less well known is that using a rotary table on a CMM machine will help it work smarter.

So what’s the benefit of using a rotary table on a CMM machine? According to Jim Palmer from RPI, a leader in rotational innovation, the answer is simple:

“When it comes to measuring symmetrical or prismatic components, it’s all about simplifying your measuring procedures, increasing your CMM’s application range and effective measuring volume which in turn will increase the flexibility, productivity and efficiency of your CMM.”

The circle of life

Matt Brady at Nikon Metrology UK agrees that rotary tables bring significant benefits to CMM machines. Nikon, whose range of coordinate measuring machines represent the ultimate in CMM technology, is a longstanding customer of RPI and has been fitting RPI’s rotary tables to its CMM machines for decades.

Commenting on RPI’s rotary tables, Brady said: “We supply CMMs to aerospace customers all over the world and many of our customers say that using RPI rotary tables significantly reduce inspection time. Indeed, one such customer reduced inspection times by four hours, a saving of 40% by using a CMM machine fitted with an RPI rotary table.

“As far as Nikon is concerned, RPI delivers a fantastic product with excellent back up. If you want precision and accuracy, they are the ones to go to for. Put simply, RPI products help end users save money, time and resources.”

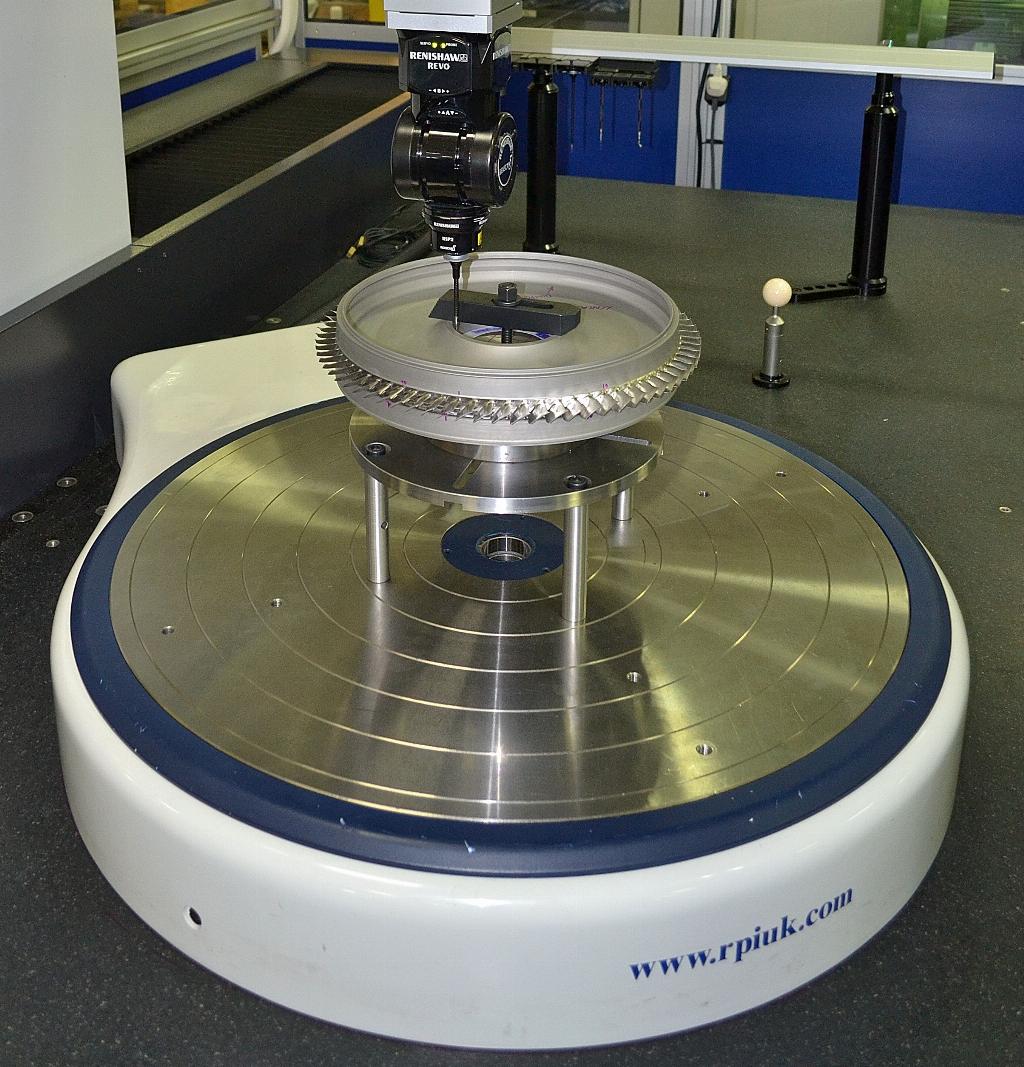

Rotary tables are therefore an ideal addition to CMM machines - particularly for measuring complex parts such as rotor discs. For example, using a rotary table on a CMM machine will improve process efficiency and productivity by reducing set up and process times. A rotary table will also greatly increase a CMM machine’s available measuring volume thereby providing greater flexibility in what can be measured. And last, but by no means least; a rotary table will also significantly improve overall measurement accuracy of a CMM machine thereby reducing uncertainty.

Bath-based RPI has a very large share of the market in those CMMs which use rotary tables and can boast more than 500 successful installations worldwide. RPI grew out of acquisitions from Airmatic, Optical Measuring Tools, and Eimeldingen. Since the 1950s it has been one of the world’s largest designers and manufacturers of precision rotary tables and a leading supplier of rotary tables to the aerospace, automotive, power generation, machine tool, scientific and general engineering industries.

RPI’s rotary tables are widely used by all leading CMM manufacturers, including Nikon, Mitutoyo, Hexagon and Renishaw, and have been specifically designed as a fourth axis for all types of precision CMM machines. They are accurate to ±0.5 arcs seconds, which is the equivalent to hitting a golf ball at a hole more than 22km away and scoring a hole in one every time.

“Let’s say you wanted to measure a rotor disc,” continues Palmer. “Simply using a standard CMM over one fitted with a rotary table would require a machine with a much larger overall measuring volume. This is because the volume of the CMM machine is directly related to the diameter of the disc as voluminous styli systems are usually required to measure a workpiece from all sides which means a large proportion of its measuring range is required just to ensure collision-free movement of the stylus around the part.”

However, the introduction of the rotary table removes this requirement as the rotor can be presented directly to the stylus removing the requirement to access all sides. This in turn simplifies the stylus system allowing the measurement of larger workpieces in relation to the available measuring range, saving aerospace manufacturers both time and money.

Sound and round

RPI’s rotary tables come in a wide size range; from 400mm to 1,200mm and can be fully integrated to the host machine controller. One of the unique selling points of RPI’s CMM rotary tables is their multiple bearing configurations: mechanical or air combination bearing.

The mechanical bearing rotary table combines a high precision, high load capacity, roller thrust bearing resulting in excellent rotational characteristics with a pre-loaded; double row journal bearing to eliminate radial movement in the table’s axis; ideal for heavy off centred loads.

Whereas RPI’s combination bearing rotary table combines the same pre-loaded; double row journal bearing as the mechanical bearing table with a high load capacity thin film air thrust bearing. The thrust bearing uses a thin layer of air trapped between the underside of the table top and the top of the base assembly. The thrust bearing is supplied using a series of orifice plugs machined into the table base; ideal for heavy centred loads.

Because they are so well made, RPI’s rotary tables last for decades only needing servicing to be as good as the day they rolled off the production line. As you’d expect, RPI provides a comprehensive rotary table, repair, overhaul and angular calibration service.

Clearly, you don’t have to go round in circles to see the significant benefits a rotary table can bring to CMM machines used in the aerospace industry. So, if your CMM machine isn’t benefitting from a rotary table, isn’t it time you invested in some rotational innovation?