Consortium signs up to develop WET and hybrid-electric engines

A group of aerospace technology companies has announced the formation of a collaborative consortium to develop hybrid-electric and water-enhanced turbofan technology for future aircraft propulsion systems, supported by the European Union Clean Aviation Joint Undertaking (Clean Aviation).

MTU Aero Engines AG, Pratt & Whitney, Collins Aerospace, GKN Aerospace, Airbus and others aim to demonstrate the potential of these technologies to improve fuel efficiency and reduce aircraft emissions, with a goal of achieving up to 25% improvement in fuel efficiency and reduced CO2 emissions compared to today's state-of-the-art propulsion systems for short- and medium-range aircraft. The consortium is coordinated by MTU.

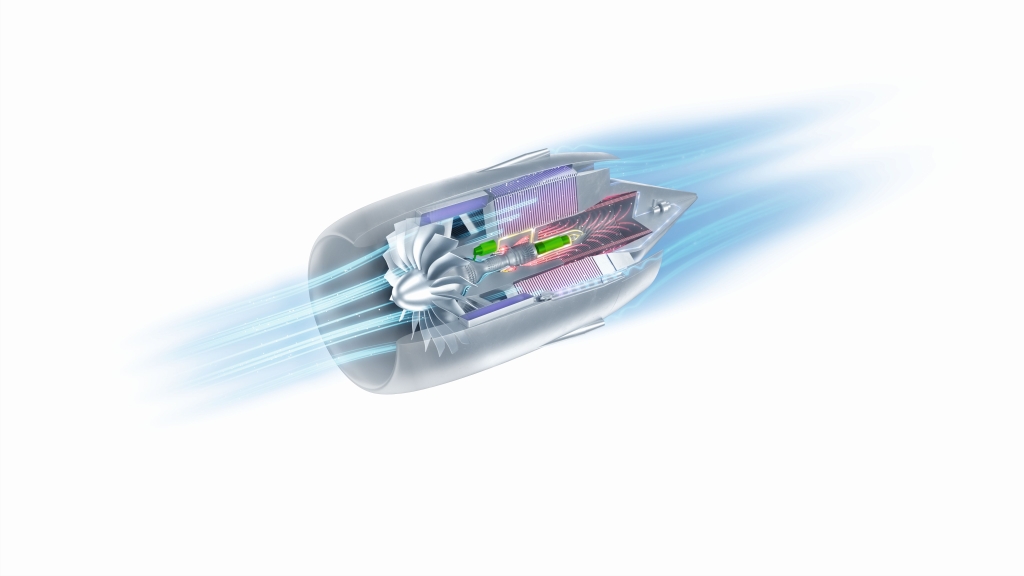

The Sustainable Water-Injecting Turbofan Comprising Hybrid-Electrics (SWITCH) project is focused on developing a novel propulsion concept built from two revolutionary and synergetic technologies: Water Enhanced Turbofan (WET) and hybrid-electric propulsion.

By combining these technologies with Pratt & Whitney’s geared turbofan (GTF) engine architecture, the SWITCH concept aims to significantly enhance efficiency and substantially reduce emissions across the full operating envelope of an aircraft. Technologies developed as part of SWITCH will be fully compatible with cleaner alternative fuels – such as Sustainable Aviation Fuel (SAF) — and will be evaluated for future use with hydrogen.

“This highly impactful SWITCH consortium provides a unique opportunity to demonstrate the benefits of both WET and hybrid-electric propulsion technologies, not only independently, but as parts of a system,” says Dr Stefan Weber, senior vice president, Engineering and Technology, at MTU. “WET offers considerable potential to boost efficiency and reduce all emissions significantly for future aircraft propulsion systems, whether they are powered by conventional kerosene, SAF, or even hydrogen. Since the concept is gas turbine based, the WET concept fully leverages MTU’s expertise.”

The hybrid-electric GTF powertrain will enable even greater efficiency across all phases of flight by leveraging highly efficient megawatt class electric motor generators, power electronics, and batteries to optimise the performance of the fuel-burning gas turbine. The WET concept recovers water vapour from the engine exhaust and re-injects it into the combustion chamber to significantly improve fuel efficiency, reduce NOx emissions, and lessen contrail forming emissions.

These revolutionary technologies are designed to work together to deliver a step change reduction in emissions and energy use across the full operating system, while maintaining world class reliability and operability.

“This project will enable us to advance several key technologies on our roadmap to further extend the efficiency of the GTF engine architecture,” said Geoff Hunt, senior vice president, Engineering and Technology, at Pratt & Whitney. “Given the challenge of reducing the environmental impact of aviation, cross-industry collaboration and public-private partnerships like Clean Aviation will play a vital role in delivering the technology breakthroughs needed to make net zero emissions aviation a reality.”

Airbus will provide key expertise relating to the future integration of SWITCH technologies at the aircraft-level and will support the evaluation of performance benefits including aircraft design and integration of battery and energy management systems.

Collins Aerospace will provide megawatt-class electric motor generators and power electronics, high-voltage DC distribution and protection, thermal management components and nacelle architectures for the project.

GKN Aerospace will develop various engine structures with all-new functionalities, such as integrated electric machines and heat exchangers.

Current funding for Phase 1 of SWITCH extends to 2025 and will include testing of a hybrid-electric GTF engine, WET technology and sub-system laboratory testing, and design activity around an integrated hybrid-electric and WET cycle propulsion system. Subject to successful testing of these key technologies and component designs, further phases of ground testing and flight tests are expected to follow.

Clean Aviation is a public-private partnership co-funded by the European Union between the European Commission, the aerospace industry, and research institutes, dedicated to advancing transformational aircraft technologies which will help enable net zero emissions for aviation by 2050. The project will be supported by UK Research and Innovation, and will leverage collaboration between multiple aerospace companies, universities and research organisations across 11 countries in Europe and the United States.

Participating organisations:

- MTU Aero Engines (Germany, Poland)

- Pratt & Whitney (USA, Poland)

- Airbus (France, Germany, Spain, UK)

- Collins Aerospace (France, Germany, Italy, Ireland, UK, USA)

- GKN Aerospace (Sweden, Netherlands)

- Aristotle University of Thessaloniki (Greece)

- Chalmers University of Technology (Sweden)

- DLR German Aerospace Center (Germany)

- University of Stuttgart (Germany)