Derwent Aviation advances claims for new booster

UK-based aerospace technology company Derwent Aviation says it is looking for a wider industry platform to further develop new aero engine architecture which, it claims, will halve NOx emissions and deliver significant benefits in cost of ownership. The package could be available to operators by 2025.

Derwent's Dual Drive Booster (DDB) is currently being developed in conjunction with performance analysis experts within the industry as well as university research centres in the UK and Germany.

Charles Cuddington, Derwent's chief executive and former managing director of Rolls-Royce's civil engines business, says the DDB concept can deliver major benefits to a variety of applications, in particular more-electric and hybrid aircraft.

“We are excited by the potential of the DDB and we believe we have the industry's attention. Now we're looking to the leading manufacturers with their resources to join us in taking the project to the next level.”

Patents have already been granted for the DDB in the United States, China and the UK and are pending in the rest of Europe.

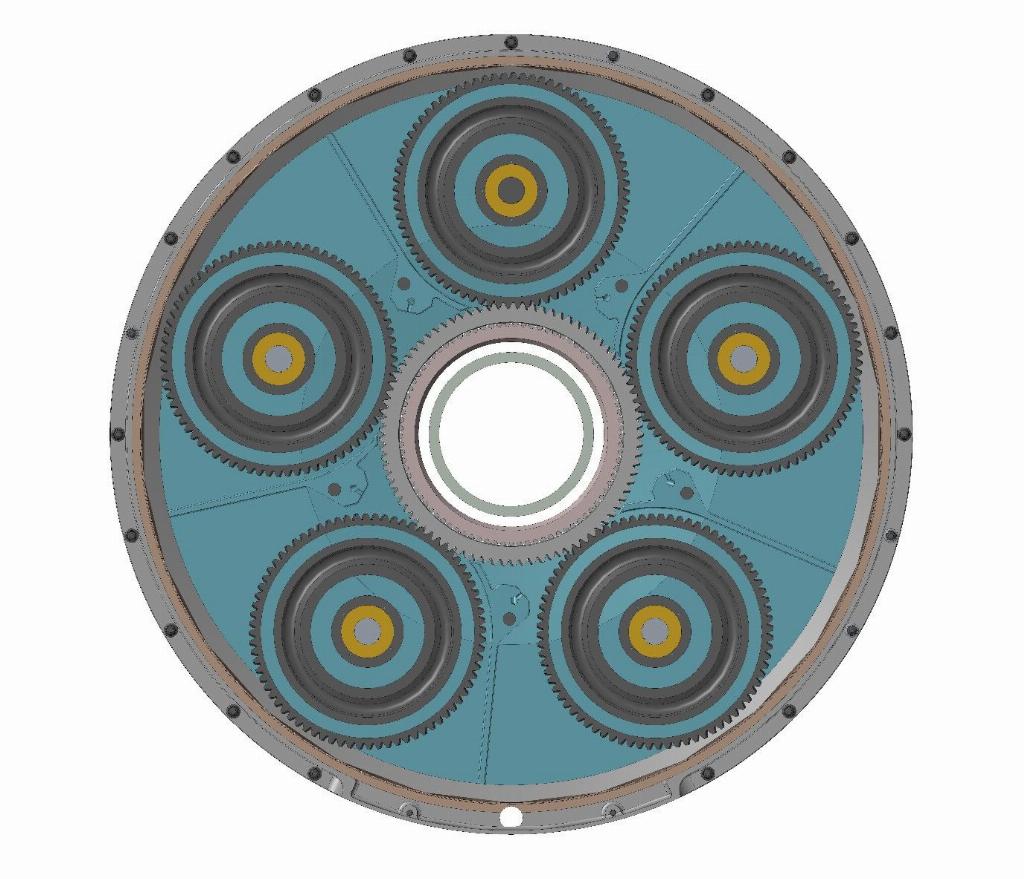

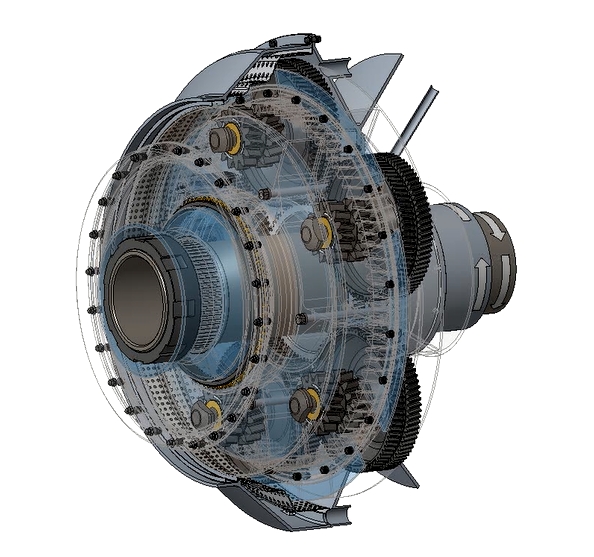

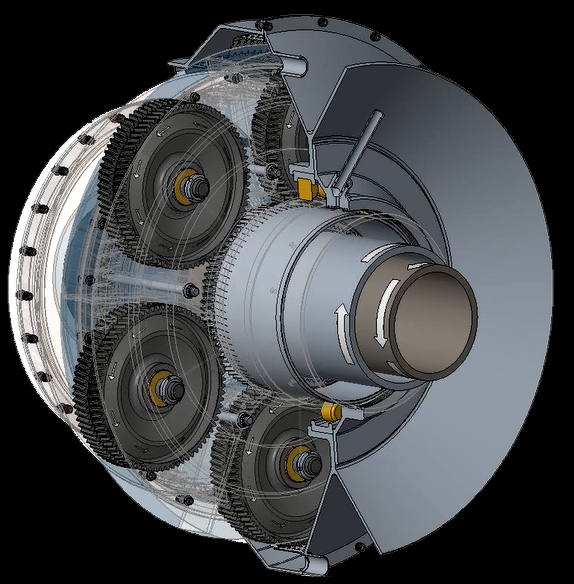

The DDB transforms the performance of the booster compressor on conventional two-shaft high bypass ratio engines by driving the booster from both the low pressure (LP) and high pressure (HP) shafts. This involves an epicyclic gearbox in which the LP and HP shafts provide the input while the output drives the booster compressor.

Utilising advances in gearbox design, studies have found that the DDB enables significant amounts of additional power to be extracted from, or returned to the engine. This can be achieved without compromising engine operability, which is not possible in conventional two-shaft gas turbines.

Given the likely option for the new booster's use with more electric configurations, Derwent's development team is also investigating the potential for an embedded generator/motor driven directly by the internal gearbox, which would rule out the current requirement for an accessory gearbox mounted externally on today's engines.

A 40% scale 3D printed model of the Dual Drive Booster can be seen on the University of Nottingham's Stand at Farnborough located in the Innovation Zone in Hall 3. The University team have verified the loads and stresses of the mechanical design and are currently optimising the oil scavenging system.

Derwent is beginning discussions with Nottingham to explore the possible involvement of its Electrical and Electronic Engineering Department in future studies of the more-electric/hybrid version of the DDB.

Meanwhile, Derwent is also collaborating with Aachen University in Germany which has used a modified version of its Gasturb software for performance modelling of the DDB engine including comparisons with current two-shaft and geared fan engines.