Dispensing on the fly

DELO Industrial Adhesives has developed a new two-component adhesive for aircraft interiors.

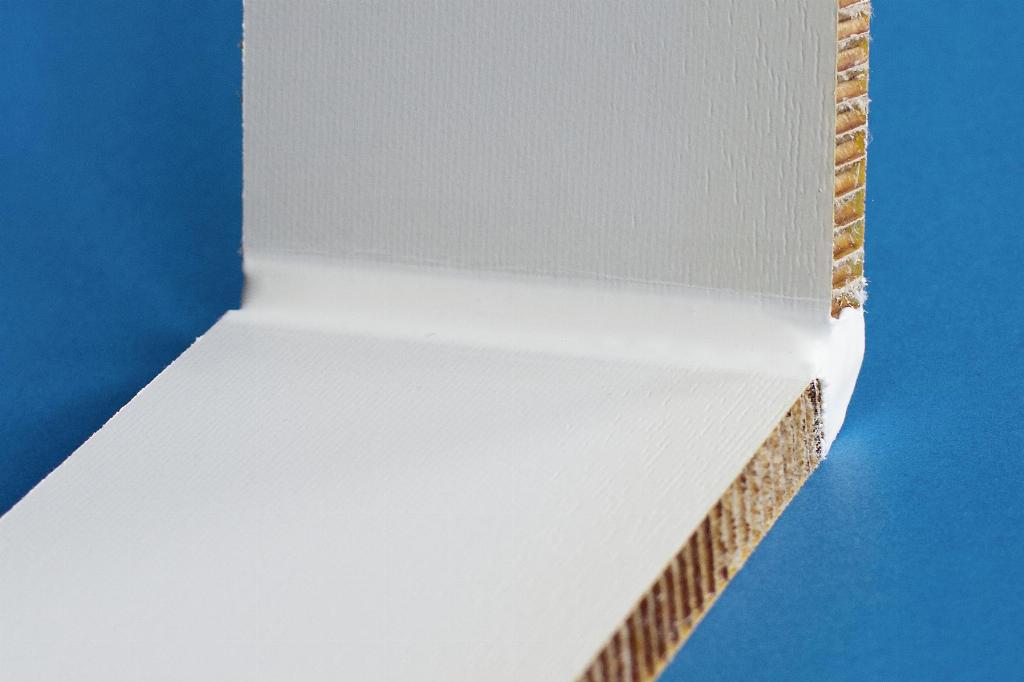

DELO-DUOPOX AB8390 is particularly well suited for the bonding of lightweight sandwich panels and fulfils, among others, the requirements regarding FST. This construction adhesive has been developed especially for use in aircraft interiors and features important properties such as good resistance in the temperature range from -55°C to +85°C.

The adhesive is colourfast in white and will remain so, which has been proved in a storage test during a time period of 1,000 hours at +70°C and an air humidity of 85%. In contrast to other adhesives which can yellow strongly, DELO-DUOPOX AB8390 offers a robust colour result for quality applications.

The DELO-AUTOMIX dispensing system allows the thixotropic epoxy resin to be quickly and easily applied, just like a one-component adhesive. During manual processing, the processing time of 30 minutes also allows a rework on the component. The adhesive cures completely at room temperature. To reduce the cycle times in production, higher temperatures, e.g. 60°C, may accelerate the curing process.

Due to the optimised dispensing behaviour in combination with the high resistances, this flame-retardant construction adhesive is not only predestined for load-bearing connections with inserts but also for adhesive bonding in the field of ditch & pot applications.