All for one, and one for all!

Mike Richardson caught up with Doncasters Group’s chief executive officer, David Smoot to learn more about the company’s showing at the last Paris Airshow and its endeavours in the aerospace manufacturing sector.

Mike Richardson caught up with the Doncasters Group chief executive officer, David Smoot to learn more about the company’s showing at the last Paris Airshow and its endeavours in the aerospace manufacturing sector.

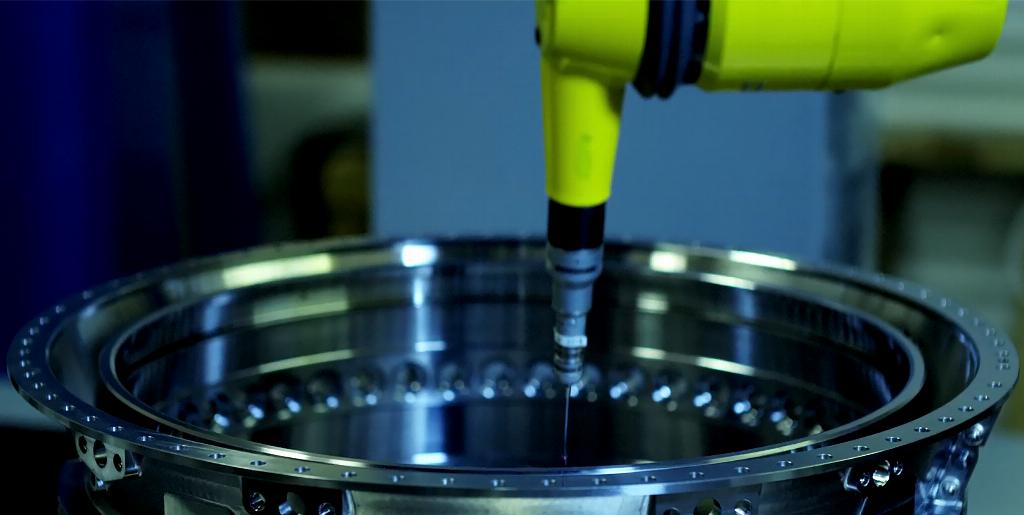

Leading international manufacturer of high-precision alloy components, Doncasters Group recently entered into a Framework Agreement with Rolls-Royce that involves its range of manufacturing sites. Doncasters currently supports a number of existing platforms across civil and military aircraft programmes with parts comprising castings, forgings, fabrications, machined components and assemblies. These are supplied through its facilities in the UK, Europe and the US depending on the part configuration, and required manufacturing processes.

The Framework Agreement embodies the principle of ‘one contract, one supplier’ with Doncasters Group, which is fully-aligned with Rolls-Royce’s plan to transform its supply chain approach, creating more transparency and agility in the procurement process.

The agreement is the first phase in a joint business approach that allows for the consolidation of mature and legacy parts production into Doncasters, reducing overall lead-time, from identification of the part to finished production, and providing better overall total value for Rolls-Royce in servicing the future delivery needs for the defined parts.

According to chief executive officer, David Smoot, Doncasters Group’s customers are demanding sustainable and predictable rates for the investment castings, forgings, and complex fabrication commodities it produces.

“The goalposts move continuously as various aircraft platforms are introduced, and take root in the marketplace and as the OEM gather the rest of the supply chain,” he begins. “Therefore, the pressure on all suppliers and ourselves is relentless in ensuring we meet that ‘drumbeat’ requirement. This is where we have put a tremendous amount of focus over the last few years; we actually want to get ahead of the curve.

“Typically, in our industry for the quantities we produce as a risk mitigation strategy, most OEMs will opt for a dual source – generally speaking, no more than two sources, which is a wonderful place to be. You want to be number one or number two supplier – you want to be working on that component and that particular engine programme. Our focus has been to develop the new parts and then industrialise their series production. We’ve done this successfully and we’ve come through the tough areas of the whole development cycle.”

Piece by piece

However, Smoot says this isn’t enough. Manufacturing the first article or some test pieces and moving onto an initial rate of one or two pieces each week is good enough to get some test engines completed and some early production made, but now the requirements are at least four per week and then doubling again by the end of the year.

“If we look at the last five years, Doncasters has historically invested on average about 3% of sales into capital expenditures. This year we are investing 10% of sales into capital expenditures which demonstrates a clear indication of the seriousness by which we take our customer commitments. We’re making similar investments above the line in terms of taking on costs to hire people, put in place skilled labour, supervision and engineering resource to ensure we can actually deliver on the customer promise, which is not, for example, last week’s two per period, but doubling again and again. I feel very good about our ability to deliver on our existing promises.

“We’re not complacent about what we’ve won over the years and just sitting back for the lifecycle of an aircraft programme. We have a huge incremental opportunity to take additional share where we are dual sourced from a second supplier that perhaps isn’t performing, so that we can actually pick up these volumes too. Given the challenge I mentioned to get to rate as other rate requirements on top of that are set across the programmes, we see second suppliers that are failing to meet their customer’s requirements. This creates a great opportunity for Doncasters to circle back around and win incremental business from the programmes that have been awarded.”

Let’s get connected

Introduced to improve joined-up thinking across the entire supply chain, Industry 4.0 is increasingly finding traction within an industry not always known for its speed of part production, but definitely for its certainty of quality. Smoot says Doncasters is fully onboard with this latest philosophy, but equally he understands that the company has to walk before it can run.

“We need robust business practices in place before we can automate them. We’ve insisted upon them with a certain amount of ferociousness and over the last few years it’s meant ensuring we have the right information technology tools to help us. It’s really simple and everyone on our shopfloor understands what this looks like – not just on a yearly basis, but on a daily basis too.

“We’re investing in upgrading our information and management systems. Many of these opportunities present themselves to us because the Doncasters Group has grown both organically and inorganically over the years and we have a number of operating and management systems under one roof. Therefore, an immediate opportunity for us is to consolidate under a single platform. I’m a big devotee of Industry 4.0. It’s about visualising our standard work procedures and thinking through the most efficient way to do things from start to finish.”

The power of people

However, the most important asset of any company is undoubtedly its people. Anyone can purchase capital equipment and introduce raw material at the beginning of the production process, but it’s how you convert it into a finished product at the other end that makes all the difference. This, says Smoot, is where the tremendous engineering know-how and the skill of Doncasters’ employees comes into play.

“We possess tremendous strength in metallurgy relating to hard alloys, which manifests itself throughout all our disciplines - whether it’s the production of the alloys, castings, forgings or fabrication,” he concludes. “We focus on the exotic alloys that are hard to work with because this is what we do really well. Moving forward, we anticipate taking advantage of the tremendous growth opportunities over the next few years and continuing to build our existing base. Execute, grow and invest – this is what the Doncasters Group is all about.”