When innovation meets rationalisation

Global aircraft component supplier, Elasto Proxy’s sales manager, Roberto Naccarato explains why aerospace manufacturers now need fewer component suppliers.

Global aircraft component supplier, Elasto Proxy’s sales manager, Roberto Naccarato explains why aerospace manufacturers now need fewer component suppliers.

Aerospace manufacturers are facing increasing pressure to extract greater value from their supply chains. They don’t want to become overly dependent on a single vendor or a handful of vendors, but there are costs – and risks – from having too many component suppliers. There are also benefits to reducing the number of component-level vendors that you do business with.

For starters, aerospace manufacturers can secure lower prices with fewer payments and better terms. Vendor monitoring is easier. Shipping is less expensive. Faster handling and more efficient stocking saves time and money, too. Of course, not all component suppliers provide the type of value-added services that support vendor consolidation. Here’s what you need to know to strengthen your supply chain.

Vendor consolidation can increase your purchasing power. Instead of buying aerospace gaskets from Vendor A and vibration mounts from Vendor B, you order both items from the same component supplier. This provides you with greater leverage during price negotiations. It’s similar to the volume discount you receive when you order more of a single item, but you’re saving money with multiple stock keeping units (SKUs).

Fewer payments, better terms

Lower prices aren’t the only reason to reduce your supplier list for aerospace components. Processing payments is easier when there are fewer supplier invoices to receive, review, approve, and pay. By reducing the amount of time spent processing payments, you can reduce overhead costs. You can also secure more favourable payment terms since you’re buying more from the companies that you do pay.

Monitoring performance is simpler when there are fewer vendor scorecards to send, receive, discuss, and act upon. That’s not all either. Just as there’s a cost to processing payments, there’s a cost to adding and maintaining vendor data. Entry-level personnel can add basic vendor information to internal systems, but scorecards usually involve more senior (and more expensive) personnel such as sourcing managers.

Vendor consolidation can also save aerospace manufacturers money on freight. Instead of paying to ship a box of rubber gaskets from Vendor A and a box of rubber grommets from Vendor B, you pay for one shipment instead of two. Consolidated shipments, the result of combining multiple less-than-truckload (LTL) shipments into one full container, can also help you to earn preferred rates from carriers.

Reducing the number of shipments can reduce your handling costs. Receivers still handle the same number of items, but with increased efficiency. With a single bill of lading, there are fewer documents to open, read, and scan or input. Instead of opening and unloading multiple cardboard boxes, a receiver can spend less time handing packaging materials. There’s less packaging waste, too.

Vendor consolidation can also support more efficient stocking operations. When multiple SKUs arrive in a single shipment, inventory personnel may be able to load a pallet truck with all of the items and then move through the warehouse to each stocking location. That’s more efficient than partially-loading a pallet jack with an item, stocking the shelf, and then returning to the receiving area for the next shipment.

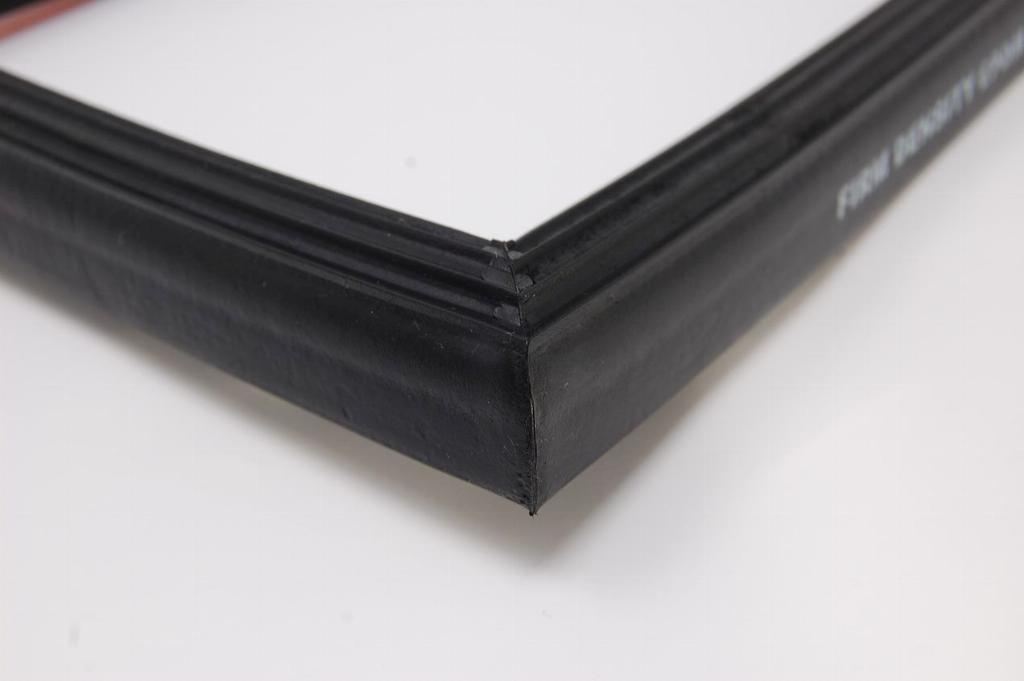

Vendor consolidation can save you time and money, but you’ll need to choose a company with the right capabilities. For example, aerospace manufacturers that need low-to-medium volumes of fluorosilicone gaskets won’t have to wait for or pay for tooling if they choose a vendor that uses water jet cutting. If this same vendor supplies rubber grommets, you can buy both products from the same source.

Aircraft manufacturers can also choose component suppliers that provide value-added services like parts marking, kitting, and custom packaging. At a time when many companies are facing a shortage of skilled labour, it’s important to maximize every labour resource that you have. Welders who spent time looking for parts aren’t welding, and maintenance technicians who wait at parts counters aren’t repairing aircraft.

Companies that use fewer component suppliers may also be able to source seemingly disparate services from the same place. For example, some gasket fabricators distribute moulded rubber parts, warehouse finished goods, and provide industrial sewing services for aircraft seat cushions. Extracting greater value from your supply chain is possible, but you need to know where to look.