Ensuring safety requires the right wheel inspection equipment

According to Centurion NDT, a wide selection of probes and accessories, along with reliable eddy current equipment, is necessary to accurately detect wheel defects.

To ensure safe aircraft take-offs and landings, one of the most vital areas to inspect for possible fatigue cracking and heat damage is the wheel bead seat, the critical area where the rubber edge of a tire contacts the wheel. The problem is that this requires having the right wheel inspection equipment on hand for the job – and not all MROs do.

The preferred approach to test wheels made of aluminium or magnesium alloys for cracks or other damage is to utilize eddy current devices along with wheel-specific probes. The critical area is the wheel bead seat, which is the area most likely to fail as a result of fatigue or heat damage.

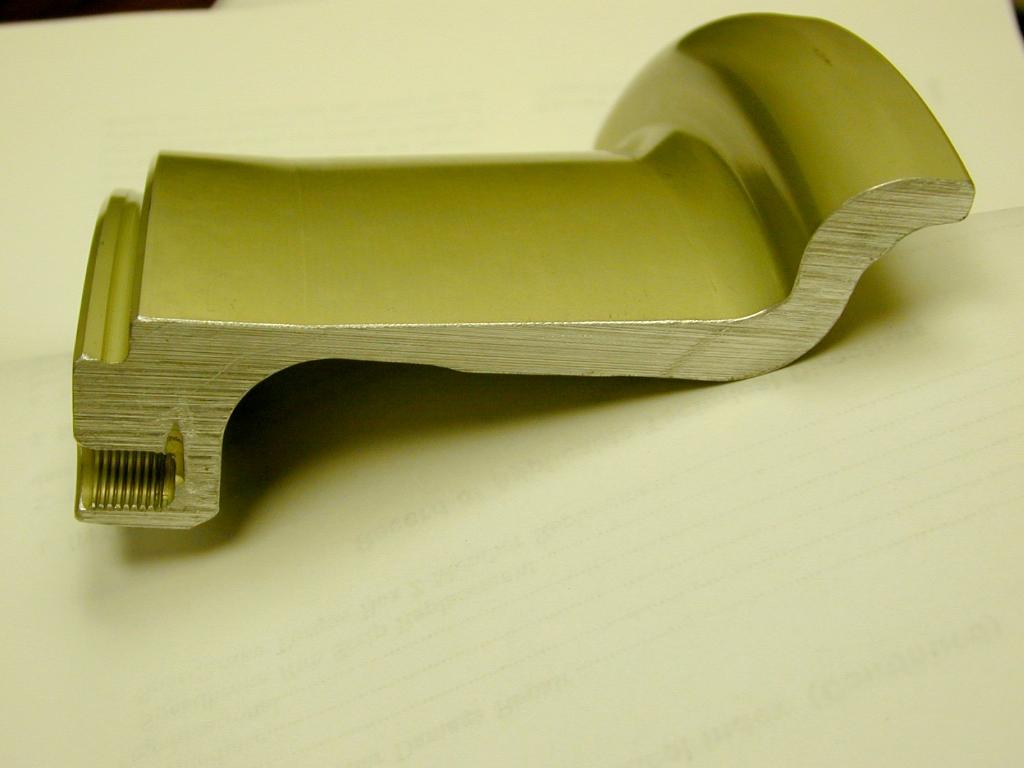

To prevent such failure, maintenance personnel must be able to perform eddy current testing with probes that fit the precise size and measurements of the wheel bead seat.

Eddy current testing – a non-destructive test (NDT) method that uses electromagnetic induction or electricity and magnetism to create a magnetic field in the item inspected – is very effective in detecting a wide range of flaws such as small cracks, surface defects, and heat damage etc. These sophisticated NDT devices provide extremely accurate wheel inspection results when paired with the correct probe.

However, in the aviation industry almost no two wheels are alike, with many varying in size, diameter and circumference. A single large wheel manufacturer might have up to hundreds of different wheels. This presents a challenge for many MRO operations because when testing the contact of the probe with the surface of the wheel bead seat is critical, so often a wide range of wheel-specific probes are required.

“The circumference and radius of the wheel is usually different for every single make or model of airplane from the Airbus A-300 to the Westland EH-101,” says Ken Strass, owner of Centurion NDT, a manufacturer of portable eddy current and ultrasonic instrumentation that makes a wide variety of probes and coils. “This is true of both main and nose gear wheels.”

On top of this, aircraft manufacturers are continuously updating or reformulating different aircraft.

“The 737 is up to revision eight, the 737 Max,” says Strass. “Aircraft manufacturers may also have long range versions, and the wheel itself may be slightly different because the tires are different.”

Because of this, suppliers such as Centurion NDT must be able to offer an extensive library of aviation wheel bead seat probes to accommodate the variety of wheels manufactured for the industry.

Eddy current instrumentation

In addition to having the appropriate probe on hand for the aircraft wheel, it is also essential, of course, to have a reliable, easy-to-use, eddy current device.

As an example of this, the company’s eddy current device, the ED-1100, has been incorporated by Goodrich Corporation as an instrument to use in wheel maintenance inspection. Goodrich Corporation is a global supplier of systems and services to the aerospace, defence and homeland security markets.

It is used for a variety of applications including detecting flaws in aircraft wheels, struts, propellers, hubs and engine components. It uses absolute, differential and reflection probes to detect flaws or determine properties such as conductivity, hardness, alloy type, and heat treat condition.

Unlike traditional all-digital units, the instrument has an automatic balance/null feature that substantially reduces set-up time for manual operation. By moving the probe and turning a phase control knob on the front panel, lift-off can be completed in seconds.

As an example of wheel testing, a Goodrich Non-destructive Testing (NDT) Manual describes an eddy current test with a contour bead seat probe. The procedure inspects for cracks in aluminium or magnesium alloy wheel halves and wheel bases.

To inspect wheel halves, wheel bases, or side rims with a contour, differential-coil, bead seat probe, the manual states to put the probe in the bead seat of the part and press the balance or null button on the instrument to centre the indicator dot on the display.

The manual also states to put the wheel half, wheel base, or side rim on a turntable, hold the probe firmly on the bead seat, and slowly turn the part until the full bead seat is inspected. It instructs to turn the part (or move the probe) at the same speed that was found to give the best signal in the calibration procedure.

In such a procedure, moving the part or probe at a constant speed can be essential to obtaining a good eddy current reading. Because of this, to improve accuracy and ease testing of the wheel bead seat, some companies like Centurion NDT also offer a motorized wheel turntable accessory.

Instead of manually running the probe around the wheel, which can lead to less reliable test results, the motorized turntable provides a constant rotational speed specific to the diameter size of the wheel half. This enables the inspector to simply hold the eddy current probe in place as the wheel spins.

The constant rotational speed gives accurate and repeatable results. With greater consistency, even the smallest cracks are more clearly visible on the screen, without the more erratic results common to manual methods.

“Passenger safety and airline reputation is on the line during every take-off and landing,” says Strass. “So, aircraft repair stations and MROs need to ensure that they have the right equipment for safety inspection available including eddy current devices, wheel probes and accessories.”