Five times faster finishing

Tübingen-based machining specialists, Walter reveals how its new turning inserts speed up finishing operations on heat-resistant high-temperature alloys.

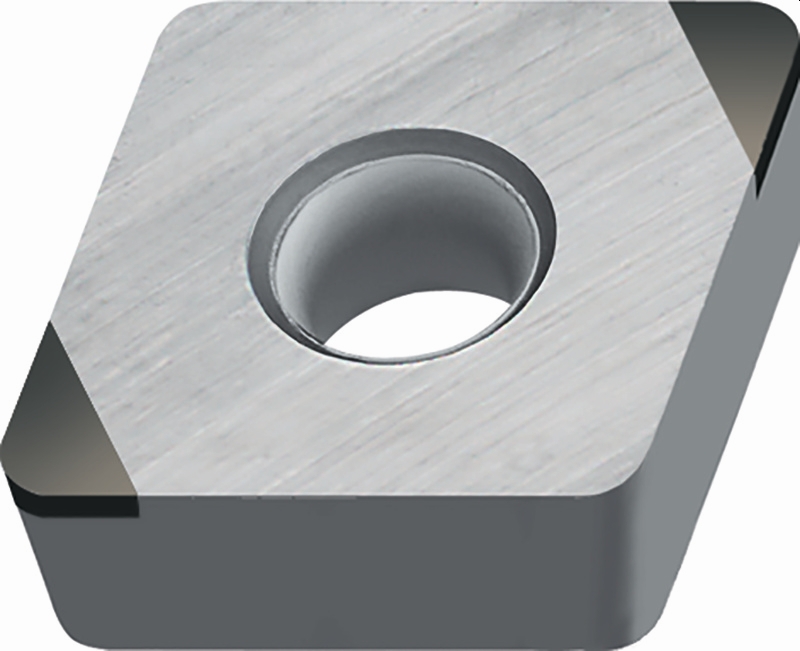

There are three trends in the aircraft industry which play a crucial part in the machining of components: Increasing quality standards, improved process reliability and reduced production costs. The new CBN turning inserts from machining specialists, Walter meet these requirements.

The materials used in aircraft construction, such as heat-resistant high-temperature alloys, place strict requirements on the machining processes. Increasing the cutting speed to improve productivity and reduce production costs does not work with carbide cutting tool materials. This would only cause turning inserts to wear at a faster rate, with the associated consequences for the surface quality of the component. The new WBS10 CBN cutting tool material from Walter, on the other hand, allows a five times greater machining speed to be achieved during finishing than with carbide indexable inserts. The CBN indexable inserts also deliver the same, consistently excellent surface finish until the end of their useful life.

In the field of aircraft construction, heat-resistant high-temperature alloys are primarily used in engine production. They must meet particularly strict requirements in terms of surface quality and process reliability, which are secured through a complex certification procedure. There are three key factors when finishing components produced from high-temperature alloys: Surface quality, tool life and speed. Tool life in particular plays an important part for large components. Only a long useful tool life of the turning tool guarantees that a surface can be finished without the need to change the indexable insert. If the indexable insert needs to be replaced during a finishing operation due to signs of wear, this produces a slight ridge that compromises the surface quality.

Strict cutting tool material requirements must be met when performing finish turning on components produced from high-temperature alloys, as both the tool and the material are subjected to considerable thermal stress. The cutting geometry and also the cutting tool material used in the turning insert have a massive influence on how effectively the thermal and mechanical stress on the component can be managed. If the tool wears quickly, this has direct effects on the surface quality. Then the requisite roughness values are not achieved, meaning that costly reworking is required. The risk of a white layer forming on the material is also higher. The combination of a rapid increase in pressure and quickly increasing heat then cause a phase transition in the material. A brittle and cracked layer appears, referred to as the white layer. The fatigue strength, wear resistance and thereby also the operational reliability of the component are reduced.

Matched to the loads

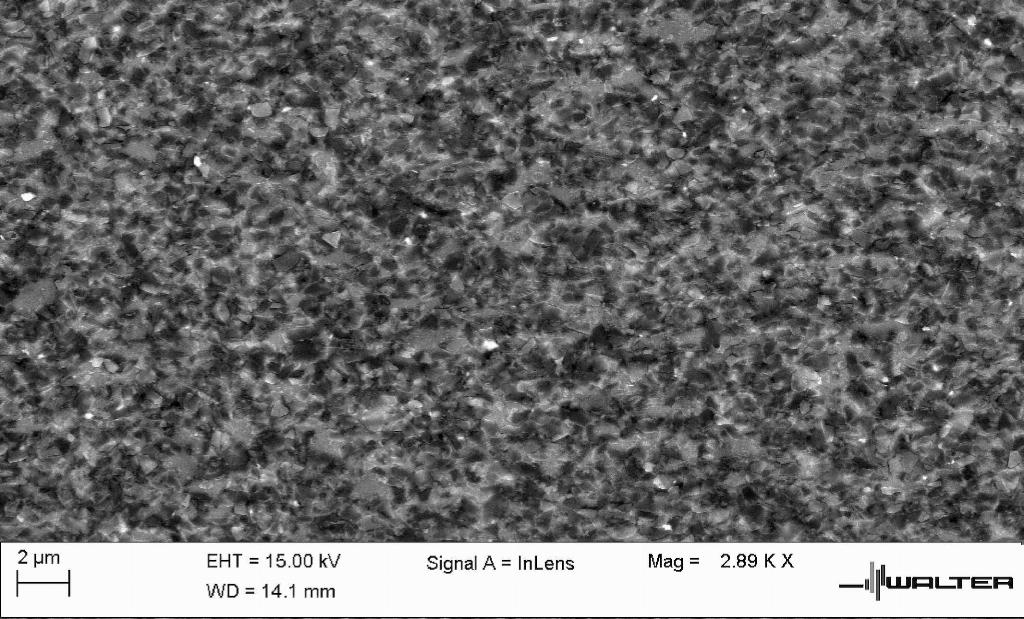

Walter has developed new CBN turning inserts in an intensive and complex process. The five-fold increase in machining speed they offer is thanks primarily to the modified cutting tool material they employ. At the same time, their cutting geometry and the cutting tool material grades used reduce both wear and white layer formation in surfaces produced from high-temperature alloys. Polycrystalline cubic boron nitride is abbreviated to PCBN. Although this is the technically correct abbreviation, the slightly shorter abbreviation CBN has become more established in common usage. Anyone with experience of cast iron and hard machining will be familiar with this synthetically manufactured composite material that is produced from cubic boron nitride and a binder phase. Adapted CBN cutting tool materials with a ceramic binder can also be used for finishing components produced from high-temperature alloys. The CBN material composite was optimised to handle the special requirements of high-temperature alloys for the new WBS10 cutting tool material from Walter. The finest grade facilitates a smooth cutting edge, which in turn has a positive influence on the surface quality from the very first cut. After diamond and cubic boron nitride, these are the hardest cutting tool material grades in the world, so the inserts are highly resistant to abrasive wear. In addition to this, they are chemically inert and heat-stable, meaning that only minimal wear due to diffusion and oxidation occurs.

Innovative cutting geometry

Modified CBN cutting tool materials alone are not enough to make the difference. An important factor here is protecting the cutting edge against excessive mechanical effects. An unprotected sharp cutting edge will break off immediately. Turning inserts therefore typically have a protective chamfer at an angle of 10° to 20°. This leads to a problem when machining high-temperature alloys. The protective chamfer generates particularly high pressure with corresponding heat build-up. Both of these factors can lead to the kind of structural transformation in the material described above. The risk of a white layer occurring also increases significantly. To protect the cutting edge, Walter instead uses cutting edge rounding for the new CBN turning inserts. This makes the cutting edge sharper, while also ensuring that it offers the requisite stability.

High quality surface finish

The machining experts at Walter are very satisfied with the results achieved using the new cutting geometry in field tests and at some initial test customers. At a cutting speed (vc) of 250m/min, the useful life of a Walter CBN turning insert is 13mins. This allows approximately 3.2km of chips to be removed. The insert also wears so evenly that no changes in the surface quality can be detected throughout its entire useful life. The average surface roughness value (Ra) is between 0.2 and 0.4µm. The component finished using the new CBN indexable insert appears almost polished to the naked eye.

The precision cooling of the Walter turning toolholders makes a key contribution to the useful life of the indexable insert. It is possible to cool at pressures of up to 150bar, although 20bar is often sufficient. It is important to ensure the optimal machining temperature. This depends primarily on the cutting speed, the cooling pressure and the material to be machined.

In direct comparison to machining with a carbide indexable insert, the new Walter CBN insert facilitates significantly more efficient finishing processes – but the process parameters need to be right. The efficiency gains can only be fully exploited in combination with modern machines, which are both stable and precise, as well as with continuous cuts.