Making a model world

Ed Hill hears how virtual reality is creating advances in the aerospace design process and creating a new industry cluster in the UK.

At the moment, virtual reality (VR) is the latest techie buzzword. It may appear that the concept is the principal domain of the video gaming fraternity or movie fans but in fact some of the technology’s earliest uses where first utilised in industry.

As VR’s applications have become broader the benefits that it offers aerospace manufacturers has become increasingly clear, especially when it comes to areas such as design and training.

A recent indication of this trend is the investment from Airbus in a new Virtual Reality suite at its Filton facility near Bristol in the UK.

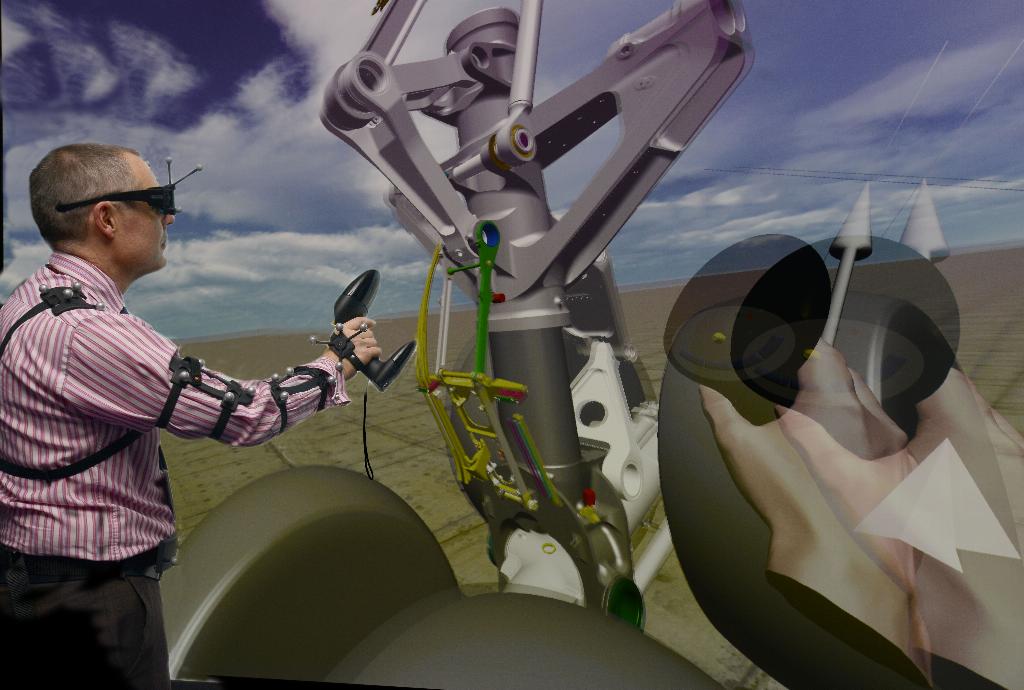

Commissioned in April 2016, the VR suite combines infrared tracking with the latest projection technology to deliver realistic three-dimensional visualisation of computer models at a full size scale.

The system takes CAD data from commonly used file formats, which reduces conversion overheads and time delays. That latest available data can then be used in the VR environment and created and modified in parallel with updates displayed in real time. This means VR projected environments can be a useful alternative to traditional real world mock-ups and 2D design iterations once common in the aerospace industry.

With the benefits of full body tracking and head mounted displays, the user can be immersed in a virtual world interacting with the 3D models in a safe environment.

This can be done with no disruption to manufacturing processes, an aircraft fleet or the need for specific safety training or equipment.

Investment in expertise

Anthony Merritt, strategic economic development manager at the development agency Invest Bristol & Bath, says Airbus’ new facility is recognition of the area’s expertise in the field of VR.

“Aerospace and defence is a key area where VR is making an impact so we are really pleased that Airbus has decided to choose its Filton base to develop and add to the cluster there involved in VR.

“It will be a test bed and centre for innovation. Airbus want to develop the new centre to increase their VR capacity in the industry and they are going to be using it in all sorts of different and interesting ways from how it has been used before.”

Barry Warburton, aerospace and advanced engineering sector specialist, at the investment agency adds: “Airbus see the possibilities of this technology, whether it’s in design, training, or the passenger experience. It’s all about interconnectivity. An additional advantage of VR is that it can be monitored and recorded which makes data easier to transfer and more traceable.

“I believe the technology will be used to research the next generation of aircraft much further into the future. For example, pilotless aircraft and the possibility that in many years to come pilots might not be needed; especially for cargo journeys. I also believe that Airbus is not just looking at this technology for its aerospace applications and you can guarantee its competitors are also developing it as far as they can.”

The South West of the UK has a growing reputation for its expertise in VR. Simon Luck is head of information services at Bath-based BMT Defence Services. He believes VR is excellent when it comes to helping with design and interface issues and visualising often complex equipment and scenarios.

“As a medium for training through simulation the application of VR in most sectors is obvious,” he comments. “But in aerospace and defence, where scenarios are expensive and often difficult to replicate, it will find an assured home. As you’d expect there is no shortage of applications in this space with numerous examples of platforms to walk into, and machinery to walk around to learn about parts and functions.

“One of the key developments in defence is the integration of virtual displays, or ‘virtuality’ into a real world. For example, the combination of VR and Augmented Reality (AR) to produce in-the-field type experiences is gaining momentum.”

Ben Trewhella, managing director of Opposable Group, which organises the VR World Congress staged in Bristol adds: “Virtual reality offers a huge opportunity for the aerospace industry. The technology offers an innovative solution to test and train in a safe and cost effective environment.”

On the inside

Airbus is an old hand when it comes to using VR for design purposes. Early versions of the technology were used to design the A380 aircraft in the 1990s.

Although the technology has been used in every area of aircraft design it is in interiors where some of its most useful benefits can be applied, particularly when combined with AR.

For example, at its innovation centre in Hamburg the company has developed 3D technology that allows its customers to walk through a virtual aircraft cabin and decide what their A350 interior should look like, such as the choice of seats, lighting and carpets, creating potentially thousands of options. The OEM also uses augmented reality inside the aircraft to perform quality checks.

Airbus is also testing various designs of commercially available headsets and glasses such as the VR Oculus Rift and Microsoft’s AR HoloLens. AR’s advantage is that it brings virtual objects into the real world making them appear and behave like solid objects through digital recognition of the user’s environment. For example, the viewer can look through the HoloLens and a floor can be transformed into the surface of another planet or a wall can become a viewing screen.

So it looks like VR, and increasingly AR, will continue to transform how aerospace designers, customers and manufacturers develop, interact and produce new products.

And for those involved in and supporting this growing field of industry including those at Bristol’s Filton aerospace cluster where Airbus is also opening a new Wing Integration Centre that can only be a good thing.

Merritt concludes: “It will enable designers to look at the next generation of technology, for example, whether it’s possible to build added manufacturing elements into the wing such as embedded sensors in composite materials.

“It’s not only those involved in design who benefit from VR. It creates a whole secondary tier of workers that are required in the industry. For example, you have software engineers building VR software, you have technicians building, developing and maintaining virtual reality suits, and installations so that MRO engineers can learn how to maintain an aircraft.

“We have evolved these skillsets in our cluster that is being more and more widely recognised for its expertise. Companies are increasingly looking for these skills sets and it will be very interesting to see how the real world applications of this technology evolve.”