Go flexible, now!

Ever faced undesired paint cracking on engine nacelles? Mankiewicz has developed a highly flexible primer coating solution that is able to withstand the movements and stretching of composites by absorbing their energy.

Nacelles are the protectors of the heart and muscles of every aircraft, the engine. They are designed to be aerodynamic, limit noise pollution, but most importantly safeguard the engine. These days special composite materials are used in their construction to reduce weight, provide acoustic protection and reinforce the structures they are part of.

Stress to the nacelles not only comes from the movements the wings make, but also from the strong vibrations that emanate from the engine. But these are not the only stress factors for an engine nacelle – erosion is another. Additionally, a nacelle often has the task of being an image booster for the airline, because it can be part of the livery that sports the its logo. All this makes nacelle’s requirements especially complex for the coating system employed. In addition, fillers and putties are commonly used on nacelles to ensure an excellent coating finish. Based on the use of these materials the complete paint system becomes more brittle and therefore partly liable for paint erosion.

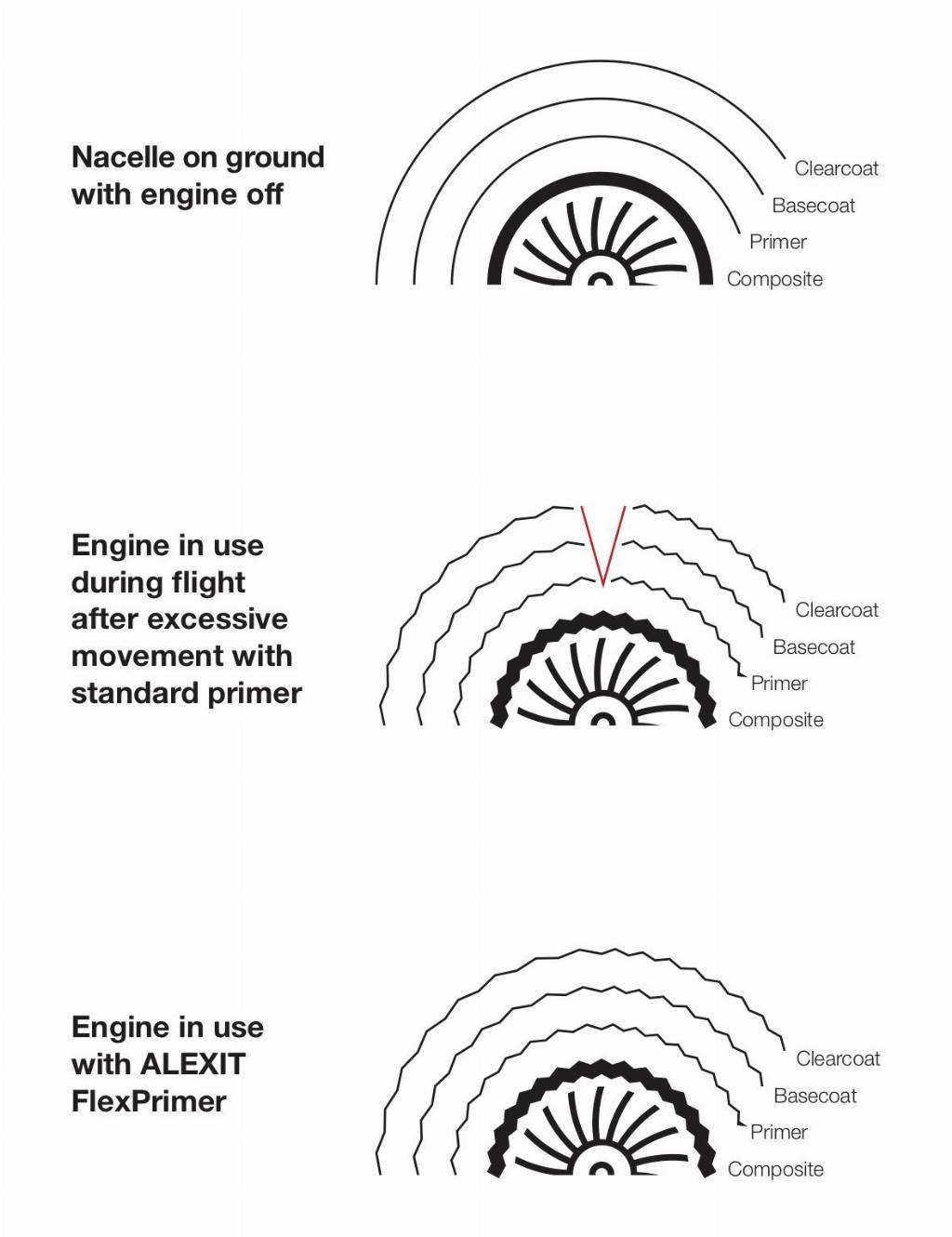

The question is whether a standard exterior coating system comprising a primer and decorative paint system can meet these new requirements of challenging surfaces. Actually, Mankiewicz’s BaseCoat and ClearCoat are flexible. However, the major vulnerability is that although exterior primers are flexible, the extreme movements that new composite materials can easily withstand still push all existing coating systems to their limits.

Promoting the coating

Composite materials can expand and move a lot, which sometimes creates extreme effects. Once a crack appears in the paint, water and humidity can penetrate; not only the paint, but also to the composite panel underneath. Due to constantly changing atmospheric conditions an aircraft is subject to, from below freezing at altitude to a runway in a desert, such cracks will expand and over time the paint can begin to delaminate. Technically, this is almost negligible as long as the composite itself is not being exposed. Once composite is exposed to light, a degradation through UV-radiation will slowly start and harm the composite structure. Furthermore, if passengers observe a defective engine shroud it’s hardly a sight that inspires confidence! For aesthetic reasons, such cracks are therefore undesirable.

What is far more serious is when movements are so great they exceed the flexibility of the composite itself – because even the most flexible material will eventually reach its limit. In this situation cracks form in the composite which at some point will also affect the primer and layers of exterior coating. When this happens a repair of the composite is technically essential.

However, returning to the original problem: what happens when the primer and coating system cannot keep pace with the stress exposed to the composite component? Either the airline simply shrugs it off, or shorter maintenance cycles are needed to repair the cracks regularly. The sanding down of composites and repainting is however very time consuming so what if it were possible to save doing this at all by substantially preventing the paint from cracking?

Mankiewicz has developed ALEXIT FlexPrimer 493-23, a highly flexible primer that withstands the movements by absorbing their energy.

During its development it was subjected to theoretical testing as well as practical application on the nacelles of various customers as part of a monitoring programme. The results were convincing for all who participated and solved a long-standing problem. And best of all: ALEXIT FlexPrimer fulfils all properties of a normal exterior primer and is also chromate-free. As a substitute for regular primer there is no need for a further layer and thus no additional weight is added.

This way the engine nacelle continues to look good, there is no reduction of aircraft availability due to unplanned maintenance and in general less repairs are necessary. The FlexPrimer 493-23 has further been successfully qualified according to OEM specifications, such as AIMS 04-04-059 to support the need for more flexible and chromate-free primers for composite structures.