The delivery of excellence

Middlesex Aerospace is looking to promote its strategic global aerospace supply chain expertise. Managing director, Laurence Foulds tells Mike Richardson how the company’s rebranding has sharpened its aerospace related endeavours.

At last year’s Farnborough Airshow, global engineering and strategic manufacturing specialist Middlesex Group, rebranded itself as Middlesex Aerospace to establish a clearer and more focused identity in the aerospace sector.

The rebranding sees the company working more closely with its suppliers to achieve the most strategic and innovative solutions resulting in the most beneficial route for all. Middlesex Aerospace claims it has grown to become the preferred partner for tier 1 and 2 aerospace organisations by combining its core competencies with its supply chain expertise.

The name change also defines key focus areas for Middlesex Aerospace. Beginning with innovation, a key element of the company’s strategy is to differentiate itself through technology by finding new, innovative solutions and ways of working that help its customers stay ahead.

“Our customers are looking for innovation in their solutions to solve their problems,” begins managing director, Laurence Foulds. “They need partners that can add value and help reduce costs. It’s not just the offer price; it’s about helping reduce the customers’ inventory to manageable levels, and provide something their customer sees as a real benefit. We help them make the big wins and sell products. We don’t just support their sales activities – we support their entire business adding value to our customers’ customer too.”

Integrate to innovate

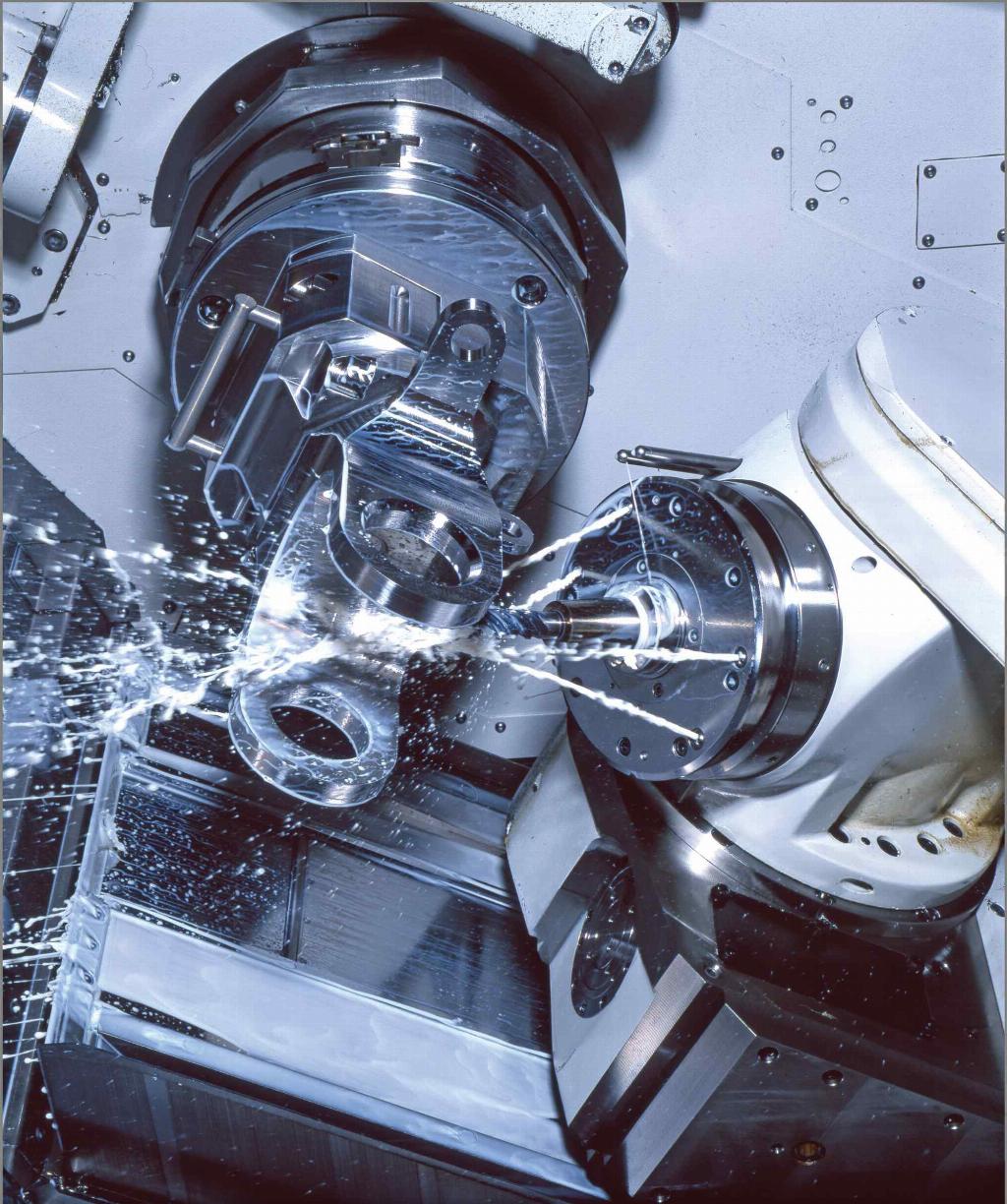

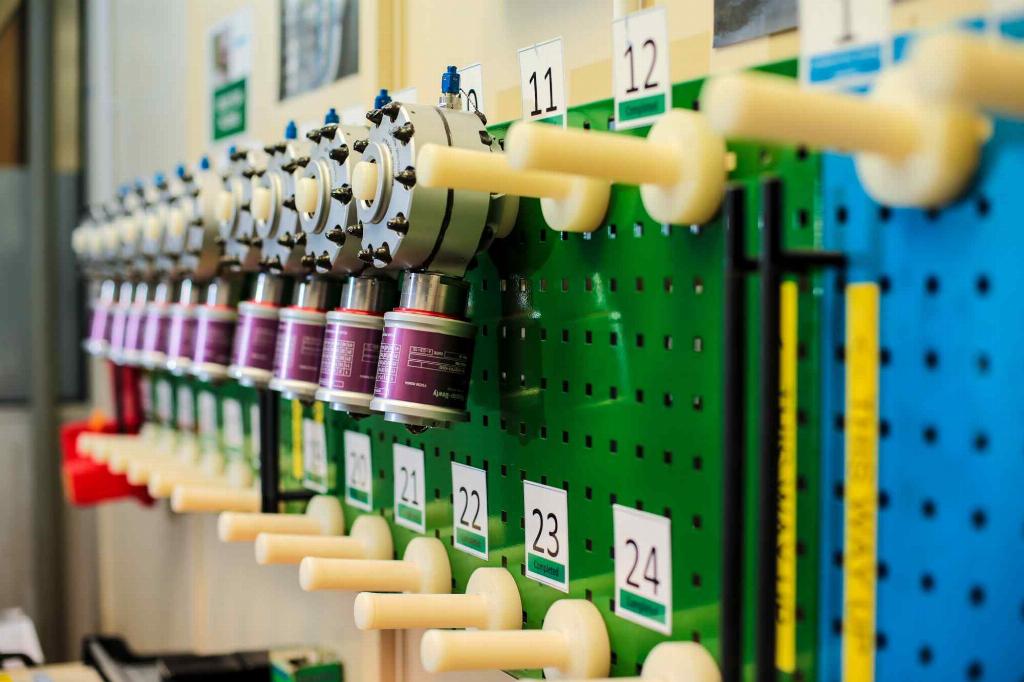

“We’re really pushing our integration concept. Our customers have historically managed approvals for their suppliers, so that if specialised manufacturing processes, such as shot peening or heat treatment are required, our customers would have previously needed to effectively approve people that are capable of doing this process. As part of our integration concept, our current and future customers are neither going to be willing or able to do this in the future because they do not have the resources to do so. There is an opportunity for us to work closely within our supply chain to provide complete solutions. If customers have existing or new products that need to be manufactured, they can contact us and we’ll oversee the entire process – from procuring forgings, to sorting out heat treatment supply, to managing all the special processes around the part – whilst we concentrate on making the complex components and also supplying any class 2 or 3 items, such as bushes, brackets from our supply chain which is global and includes low cost sources.

“By integrating our source and supply, we ‘vendor manage’ the complete solution. We’ll stock the vendor managed solution and the customer, so that a kitting engineer can take a part from a stores unit beside the assembly line and just the action of them removing the item triggers the software to email a release note and the invoicing information at that precise moment. We keep stock down to an absolute minimum. Our integrated approach is all about working with customers, so that we give them 100% on-time delivery and ensure their stock control is as good as it can possibly be.”

The final focus area is global supply. Middlesex Aerospace has invested in processes, tools and resources to achieve efficient supply chains. Migrating to an integrated planning approach has seen the company increase its service levels, responsiveness and on-time full delivery, while judiciously balancing working capital needs.

“We can obtain extremely good leverage on pricing because we have a very sophisticated purchasing team working with a very wide supply chain in the UK, Europe – especially low cost economies like Poland – and the US. We have the capabilities to obtain great deals on pricing, as well as supplying the kits and the components that any of our customers need in order to support their manufacturing.

“We’ve also introduced the first new manufacturing cell in support of one of our customers, and we’ve started work on 2-3 other manufacturing cells that will significantly reduce our production times and improve customer service. We have the aspiration to at least double our size by 2025, which we think is perfectly possible with growth on existing programmes and with new customer opportunities.

“Our USP is that we make extremely complicated components that most companies cannot make within a cellular environment. The customer provides us with a broad schedule of their requirements and we actively manage them, so that they can enjoy the peace of mind that everything is happening seamlessly in the background. We have the ability to effectively control all the activity within our supply chain.”

“It’s a long journey and we’re on it all the time. There are people in our organisation that work solely on continuous improvement programmes to ensure we are constantly moving forward and improving everything we do. Continuous improvement programmes like SC21 and Sharing in Growth, have definitely helped us to attain a better competitive advantage, but it’s important that you recognise that you can’t just go along for the ride. You must be able to derive the value you want and extract it. You can’t just assume that a third party will come into your business and sort all your problems out – life just isn’t like that. You have to actually use these people in a way where they can help you, but you have to realise that the people making the effective change is yourself. It’s not some third party sprinkling magic dust over your manufacturing problems.”

Joined up thinking

There once was a time when a manufacturing company did practically everything ‘in-house’. Those days went, then came back and then went again. In terms of the supply chain developments of the future, does Foulds believe that the industry is gradually fracturing into separate integrators or are some once again OEMs consolidating all their manufacturing under one roof?

“I see more merger activity and companies undergoing a transformation to become more integration-led. We’ve developed a separate side of our business to perform highly-specialised, high technology low quantity manufacturing – principally, in the area of the aerospace industry.

“Our total investments in new equipment run into seven-figure sums every year and we intend to carry on doing this into the future,” he concludes. “We will also be exhibiting at this year’s Paris Airshow.”

Middlesex Aerospace will be on the UK Pavilion, hall 2b, stand G187.