Abrasion by equation

As new mid-range engine programmes roll out, the demand for blisk production has never been higher, and manufacturers are constantly seeking ways to reduce lead-time and increase throughput in order to meet customer demand and projected market growth.

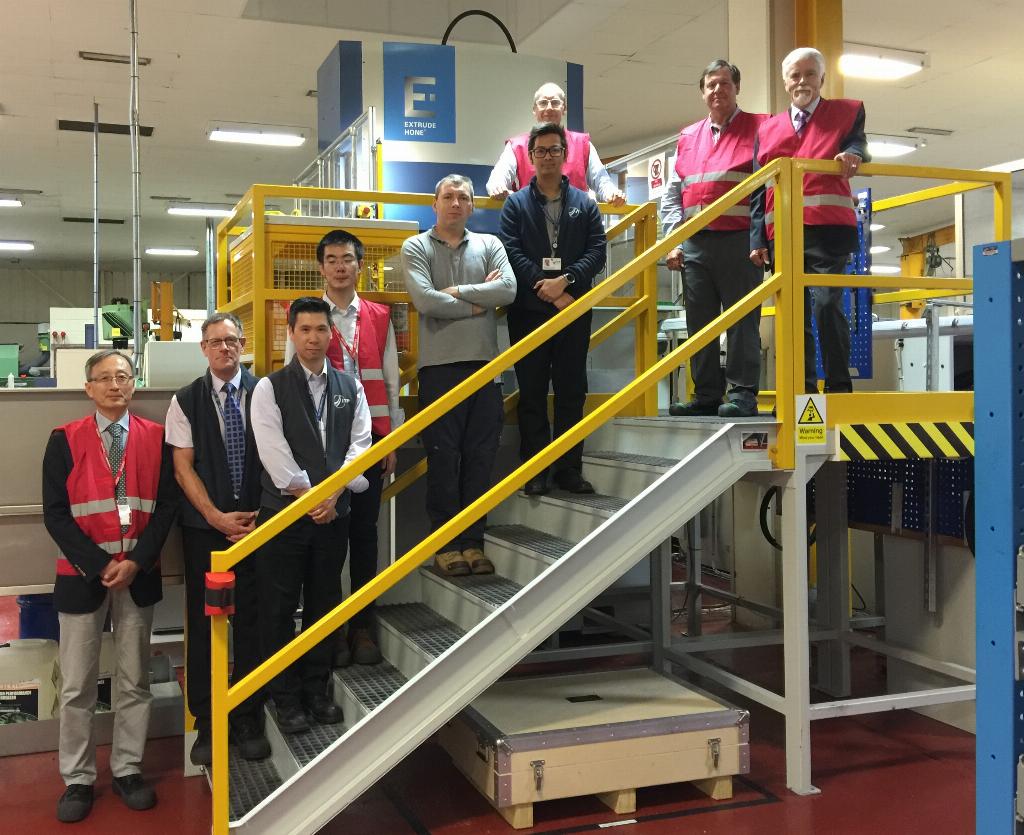

As a major player in the blisk production market, ITP, has found a surprising opportunity by looking more closely at a long-established finishing process. The company’s blisk manufacturing centre of excellence at Lincoln, together with partners Extrude Hone and Brunel University, have been getting to grips with the science behind a 50-year-old process that is used extensively after the machining of metallic parts to improve surface finish. The two-year project, which has been supported by the National Aerospace Technology Exploitation Programme (NATEP) and delivered in the Midlands by the Midlands Aerospace Alliance (MAA), has turned the spotlight on abrasive flow machining.

For many years, ITP has used abrasive flow machining to finish some of its aero engine blisks. These high value parts are manufactured from aerospace alloy forgings using expensive 5-axis CNC milling machines on which time is always at a premium. Abrasive flow machining was first patented by the Extrude Hone Corporation in 1970. During the machining operation, a viscous abrasive paste is forced backwards and forwards under pressure across the surfaces of parts to smooth out irregularities like machining marks and burrs.

Go with the flow

Abrasive flow machines, of which Extrude Hone is a world-leading supplier, have several parameters which can be varied, such as pressure and flow rate of the abrasive medium across the part. The condition of the abrasive medium needs to be maintained regularly through a programme of partial replacement. Ultimately the time during which the part is subjected to the abrasive medium is a key factor in determining metal removal and surface finish. Despite being deceptively simple in concept, the process has always been largely empirical because the underlying physics and chemistry are extremely complex and not fully understood.

As aerofoil shapes become more sophisticated, coupled with greater tolerance control, the inability to accurately predict and control the abrasive flow machining process means that it is becoming increasingly difficult to preserve key features such as leading and trailing edges. Caution dictates that some parts need to be subjected to interim measurement on CMM machines, thereby significantly increasing the manufacturing time. Once a workable solution has been found, the unpredictability of change means that there has been a natural reluctance to deviate from that solution.

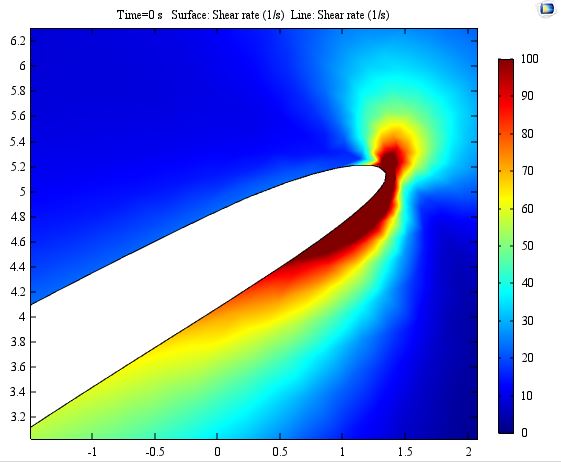

During the NATEP project, Brunel University has constructed a mathematical model of the abrasive flow machining process using the COMSOL Multiphysics modelling software and the team has validated this through a series of tests on material coupons and blisk segments carried out by Extrude Hone and ITP. These tests have allowed researchers at Brunel to refine its model to a point where excellent agreement between predicted and actual wear rates and profiles has been achieved.

The Brunel activity has been led by Professor Kai Cheng, a leading expert in advanced manufacturing who says: “Brunel has always been very keen to work with industry on solving real present-day problems and this project has been the perfect opportunity to bring new insight to an established process. Sometimes, buried in what can seem to be rather mundane processes, there are exciting discoveries to be found, which could prove to be game-changing.”

The project has already resulted in an ‘early win’ for ITP. By modelling the abrasive flow finishing of a rotating part which has numerous complex-shaped features, ITP found that it was possible to implement a significant reduction in the total abrasive flow machining process time.

Principal manufacturing engineer at ITP, Kevin Ngoe, says: “The number of variables to consider, expensive trial parts needed and time required to properly optimise this process makes changes difficult to justify. Being able to accurately model the process will make a huge difference.”

It’s a flying finish!

Whilst abrasive flow machining has proved itself to be an excellent finishing process, ITP has bigger goals in mind, and the key to success is predictability. Being able to predict accurately exactly how much material will be removed, and where from, means that ITP are coming to see abrasive flow machining not so much a finishing process as a machining process. The new thinking is to leave more stock on blisk aerofoils during milling, and then bring parts to size using abrasive flow machining. Because the process model imports CAD files for both part and tooling geometry, it’s possible to fully-design the path and velocity of the abrasive medium at all points along the part. Importantly, this can lead to a significant reduction in expensive 5-axis CNC milling time.

For Extrude Hone, managing director, Sean Trengove feels that the project opens up exciting new possibilities for its abrasive flow machines: “Although we have built up a good understanding in the application of abrasive flow machining, much of our knowledge is derived empirically over many years in the business. The ability to model the process when applied to a particular part and its associated tooling should assist us in integrating our machines into our customers’ production lines. This could also potentially open up new markets across a number of sectors.”

For ITP, this project helps underpin an investment strategy which led to the purchase of a large new Extrude Hone abrasive flow machine at its Lincoln facility. Project manager, Richard Kenny of ITP concludes: “Our factory is continually challenged by an increasingly demanding market and our R&D budget is always struggling to match our aspirations for process improvement. Being able to access NATEP funding together with support throughout the project by the Midlands Aerospace Alliance's technology manager, Peter Knight, has been a key aspect to the progress made in this project.”