Go West, young engineer!

North America’s aerospace sector is an important contributor to the country’s economy. Mike Richardson examines the good work a selection of US states do to help the nation best position the sector for long-term growth and innovation.

Any global aerospace company considering entering the North America aerospace market must first evaluate the differentiators that make any US state the most persuasive location. What differentiates each state from other investment destinations comes down to its willingness to work closely with companies looking to invest, its low energy costs, its workforce talent and the calibre of its aerospace-related R&D activities.

Indeed, a growing number of international aerospace companies are increasingly calling the US ‘home’. Over the past few years, many of them seeking to enter the US market have been investing and establishing a presence within the US. But it can take a huge leap of faith to open a manufacturing facility in North America, so Julia Mills (right below), director of Enterprise Florida, UK & Ireland (www.enterpriseflorida.com/uk) begins by making the case for the Sunshine State.

“We work with companies from various walks of life within the aerospace sector,” she begins. “Enterprise Florida supports the exporting requirements of Florida companies as well as helping UK and Irish companies to set up or expand in the state. This could mean a manufacturing facility, which is quite often the case – near an existing aerospace manufacturing cluster - or a sales and support office.

“Indeed, we’ve seen many UK companies across various sectors locating in Florida to serve the Latin American and Caribbean markets, partly due to flight connectivity between these areas. So, in terms of flight training, support activities, air transportation, aerospace products and parts manufacturing – there’s certainly a lot going on in all three locations.”

Mills adds that Florida is the third largest state in the US in terms of population, with almost 20 million people living there - including 85,000 people working in aviation and aerospace industries.

“Many companies coming into Florida have also benefited from retired military personnel moving to the state. These comparatively young people possessing key engineering skills, still have a lot to offer. Florida’s universities also contain some of the US’ top STEM graduates. So, not only does Florida have its existing aerospace and aviation workforce, but also its skilled ex-military people and graduates, are coming through universities all looking for work opportunities. If you combine this with Florida’s training programme, then prospective companies generally don’t have any issues hiring competent staff in the state.”

Off to a flying start!

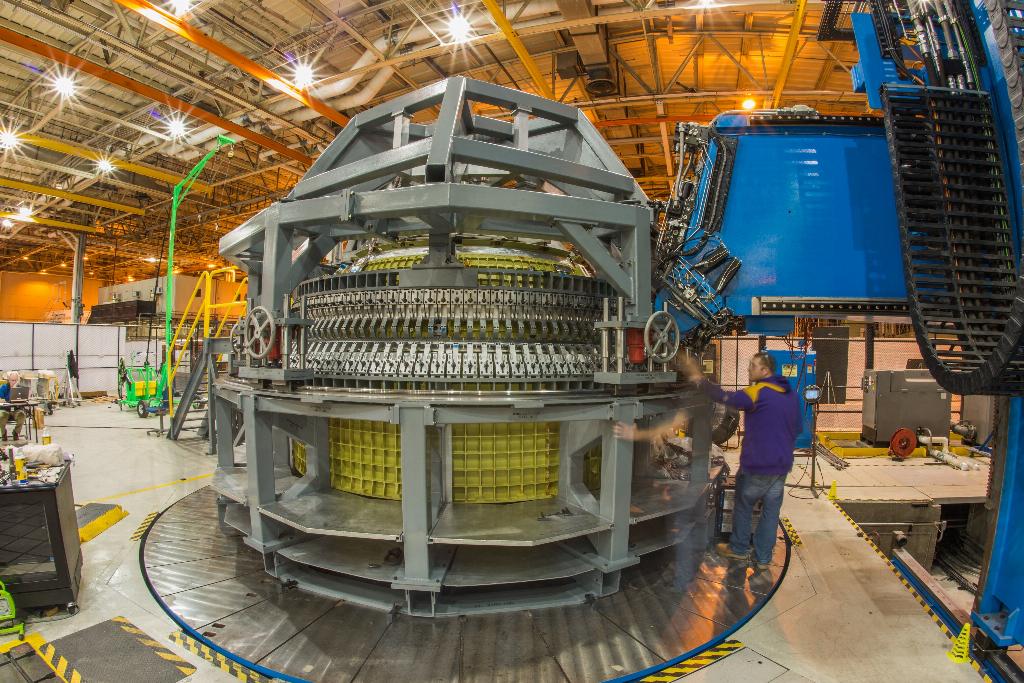

“It’s an exciting time for us in Louisiana,” begins secretary Don Pierson of Louisiana Economic Development (LED) (www.opportunitylouisiana.com). “A key element is the NASA Michoud Assembly Facility, located in the vicinity of New Orleans. It’s where the US space programme really got its ‘sea legs’ in launching the Saturn programme that took man to the moon. The Michoud facility is where NASA is building the next vehicle to lift man into orbit – the US Space Launch System (SLS). The space capsule that sits atop the SLS is called Orion, and its structure is also manufactured at Michoud. We’re arguably at the centre of man’s next space exploration activities.

“Louisiana also has a number of locations interested in growing their aerospace footprint. Here, the state offers significant workforce training activities to enable a company’s workforce to hit the ground running from ‘day one’. This isn’t just a training programme that is customised and copyrighted to the company, but offers a much more robust method by actually recruiting the right kinds of people with engineering backgrounds. This then qualifies the pool of applicants that are inside this recruitment universe. A company can choose candidates with the right aptitudes and they will be carefully trained to the specific requirements of the company.”

As Pierson rightly points out, it’s one thing for a company to relocate and find a site that is suitable, but the state in question also needs to be able to deliver a ready and willing workforce for the company too.

“We’re able to take manufacturing operations and with local resources, grant them abatement on any type of property taxes for many years. In addition, at certain wage levels we have payroll rebate programmes and a whole suite of opportunities we can customise for a company to help them enjoy the lowest production costs possible. We like to attract manufacturing-based companies to our state, because they can be tremendous job multipliers in creating other jobs within the community.”

Space, the final frontier

Elsewhere in the US, Mississippi is home to some of the world’s most advanced aerospace manufacturing. Pioneer Aerospace, part of Zodiac Aerospace, has manufactured parachute systems in Mississippi since the 1930s. NASA’s Stennis Space Centre on the Mississippi Gulf Coast has been crucial to every NASA mission since the 1960s and continues to be the largest rocket engine test complex in the US. Virtually every commercial aircraft in the world has at least one component made in Mississippi. Today, Mississippians produce everything from helicopters to composite jet engine components.

With Boeing now in South Carolina and Airbus in Alabama, Mississippi is seeing a great number of global OEMs entering the South to either do business or supply parts to these two companies. Mississippi’s strategic location and aerospace workforce expertise makes it an ideal location for investment consideration by such OEMs.

“Aerospace isn’t new to Mississippi,” explains Glenn McCullough, executive director of the Mississippi Development Authority (www.mississippi.org). “Military flights began operation in Payne Fields, Mississippi over 100 years ago, and this led to the manufacture of parachutes. Today, Mississippi is at the centre of everything from the world’s most advanced radar systems to every manned space flight in the US in the last 50 years, and from rocket engines being tested at Stennis space centre in Hancock County, to composite components, where research is done at the University of Southern Mississippi, Polymer institute. Every commercial airliner today has at least one component manufactured in Mississippi.

“We’re a comparatively low-cost, high-value place to do business. We’re a ‘right to work’ state with minimal organised union employment, a lot of R&D at the university of southern Mississippi with composites, and a number of UAS’ at Mississippi state university, as well as a physical acoustics lab at the University of Mississippi in Oxford. Our workforce is highly-skilled and comparatively low cost. We offer favourable low taxes, and we’re now phasing out the franchise tax. We also have fast permitting speeds, so companies new to the state can get its facility up and running in a very short time-frame. Finally, we’re right in the heart of an aerospace corridor: Mississippi sits in its heart – from South Carolina to Texas - so logistically, we’re in a great location to span out across the South East and West to serve other customers.”

Close to home

“If a European aerospace manufacturer decides it needs a North American location then it needs to evaluate what is the best place for them,” he outlines. “Certainly, the density of the supply chain in Washington is second to none in North America – there are other locations that make aircraft, but Washington makes nearly all of the commercial aircraft, so every Boeing 737 that has been built comes from Washington. There is so much diversity in our supply chain that Washington is an attractive place to be, especially if you combine this with our skilled workforce and the fact that Washington offers a variety of incentives to help companies lower their other tax obligation costs if they are involved in the commercial aerospace industry.”

Calhoon adds that Washington state has some of the lowest electricity costs in the world, because over 70% of its electricity is generated by hydroelectric methods.

“We have rates of 2.5 cents per kilowatt hour – an interesting proposition for composites manufacturers because they are big energy consumers and therefore need to be more environmentally-conscious. We’re unique with all these assets coming together and supporting aerospace – it’s a very big part of our economy.”

In partnership with BCI Aerospace, Washington has also established an aerospace B2B meetings event to Seattle called the Aerospace and Defence Supplier Summit - a sister event to Aeromart Toulouse and Aeromart Montreal. Held in Seattle every two years, the next event is scheduled to run from March 26-28, 2018.

“This has proved to be a great business to business event, and Boeing sends many buyers to scour the whole show and look for new technologies and suppliers to meet their specifications.”

With a mature and thriving aerospace sector, unique resources and a pipeline of skilled workers, the message is clear: if you want to enter the US market, sell your aircraft parts and/or partner with a US OEM, go West young engineer!