Serial production of 3D printed aircraft interiors project launched

Middle Eastern MRO provider Etihad Engineering, EOS and Baltic3D.eu, one of the largest industrial 3D printing centres in Northern Europe, are collaborating on an R&D project for serial additive manufacturing of aircraft interior parts.

Baltic3D has selected Laser Sintering (LS) technology of EOS among other powder bed solutions as a key competence partner considering the achievements EOS has demonstrated with qualification of their technology and materials for aerospace applications.

Meanwhile Etihad Engineering, as an industry leader implementing additive manufacturing (AM) technologies in aerospace applications, will be supporting the joint R&D efforts by conducting flammability testing at its onsite Flammability Laboratory, and providing its engineering analysis and reports, as feedback on the designs and prototypes produced within the project.

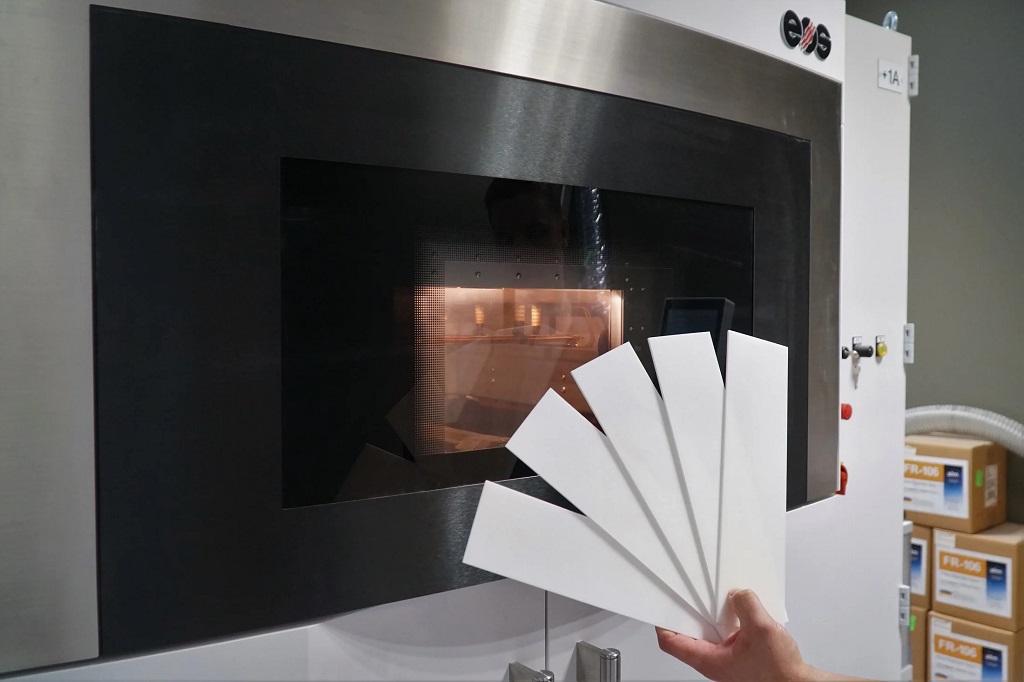

Within the R&D project Baltic3D will print over 2,000 material coupons in LS technology, using the EOS P 396 machine. These material samples will be tested at the Etihad Engineering Flammability Laboratory in Abu Dhabi, in accordance with aviation standards, including FST, heat release tests. It will be followed by creating several prototypes for aircraft interior part designs using LS technology.

Janis JÄtnieks, co-founder and board member of Baltic3D said: “From part design to the end part manufacturing and certification, the aviation supply chain is heavily hit by COVID-19. With this R&D project we aim to significantly reduce time and money for design organizations and OEMs have to invest to add additive manufacturing as additional manufacturing route to existing production or even to completely switch to complex parts production using AM. Our plan is to establish a comprehensive test and manufacturing data set that would help aerospace engineers to develop part designs for AM with high level of confidence.”

Markus Glasser, senior vice president EMEA at EOS added: “Over the last few years, we have managed to fully qualify our technology – meaning qualified materials, processes and systems for the aerospace world. Aerospace demands reliable data, which is the primary aim of this project, and thereby we firmly believe that this project will substantially accelerate the adoption of AM in aerospace.”