Software solutions for aerospace

In a series of Q&A articles from top production control software developers, Tom Dawes, CEO of Valuechain, discusses the advantages of the latest Material Requirement Planning (MRP) and Enterprise Resource Planning (ERP) software systems to integrate all aspects of a manufacturing business.

In a series of Q&A articles from top production control software developers, Tom Dawes, CEO of Valuechain, discusses the advantages of the latest Material Requirement Planning (MRP) and Enterprise Resource Planning (ERP) software systems to integrate all aspects of manufacturing businesses.

Q) What are the fundamental benefits of MRP or ERP systems?

An MRP/ERP is a coherent and integrated system that tracks and transacts on manufacturing process information, from placing requests for quotes on suppliers, tracking material through the factory, right through to issuing invoices once the finished product leaves for the customer.

By implementing a digital system to manage this process, companies benefit from having streamlined, standardised workflows throughout their business; full traceability of their jobs and are able to capture valuable data and information throughout this whole process.

All of these benefits ultimately help companies to have better visibility of their resources and machines, to be able to make informed decisions about opportunities to be more lean, minimise waste, and reduce inefficiencies.

Q) Are the days of the paper jobcard and paper management of contracts and work schedules over?

All companies start somewhere, and there’s no harm in manual processes for a period of time while you work on getting the processes right, getting the right skills and knowledge in place to create those best practice processes.

Having said that, I would also say that it’s important not to wait for everything to be in place before starting. The flip side is that companies that try to hang on to manual/paper-based processes, and keep pushing off digitisation, will simply not be able to drive productivity improvements robustly enough to remain in business, let alone compete with the best in class.

Especially in an industry like aerospace, where there are even greater demands for compliance and paperwork, and customers are now expecting a significant level of digitalisation from their suppliers.

Deploying an MRP/ERP system is step one of the digitisation journey. These solutions have been widely deployed, however, there is always room to do better. Once the MRP/ERP solution is in place and working, it opens up many additional opportunities to adopt other digitisation and Industry 4.0 technologies, where appropriate to the business and where they drive further productivity improvements with clear and measurable returns on investment.

Q) What are the specific benefits for ERP/MRP in the aerospace sector: traceability, adhering to industry standards and practices, managing materials and resources? How can they help in an industry with a highly global supply chain and cross industry cooperation between companies?

There’s a lot of stringent regulations as mentioned, and complying with these, while absolutely necessary and vitally important can be a real challenge to businesses working in the sector with manual processes. The admin and paperwork, marking up goods in from suppliers, providing status updates to customers, performing routine checks on every item and every machine – it’s a huge drain on time and personnel resources that slowly erodes away the margins, making it very difficult to be competitive.

And that’s why ERP/MRP systems are so important for companies, especially those in the Aerospace sector. And not any ERP system, but having an appropriate solution for aerospace. Ensuring that your ERP system can produce First article inspection reports (FAIR), contract reviews, and track not only goods in, but the shelf-life of these items and the chemical composition.

Being able to demonstrate compliance quickly and effectively and having it automated, to an extent, can save hours for aerospace companies, and ultimately drive excellence.

Q) Are MRP systems now superseded by more broadly capable ERP systems?

I think all businesses are different. And I don’t necessarily view it as MRP or ERP or MES (Manufacturing Execution System) necessarily - lots of people use those terms interchangeably – but really, it’s about having a system that is ‘best of breed’ for managing your business.

Every company operates slightly differently, will have different KPIs, different internal focuses, and ultimately need different capabilities from their systems.

I think it’s true that ERP systems are being offered at more affordable price ranges than ever before, but for some businesses they can be too complex, too overkill, or not specialised enough.

I mentioned before about having a system suited to your industry, and every manufacturer would benefit from having a system to manage their production, but beyond that, I think there’s an element of the ‘mass customisation’ culture (that is a key aim for Industry 4.0) actually being available to manufacturers themselves. So, they should be able to select the modules of an ERP system that they actually need; whether it’s a CRM module, scheduling, quality management or calibrations. It’s really about getting the right digital solutions with correctly trained people to support and underpin the manufacturing & business processes in the most appropriate way.

Q) How do these systems help manage the actual management of work on the shopfloor? How do they incorporate systems such as distributive numerical control (DNC) and Shopfloor Data Capture (SFDC)? How can they help schedule and prioritise jobs and ensure the most efficient use of machining time, for example?

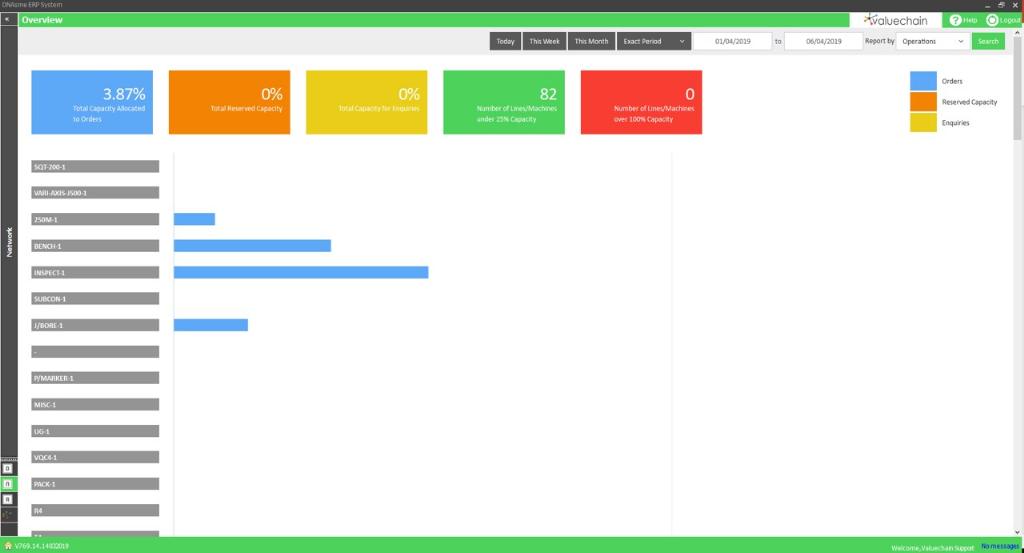

Scheduling software has become a very important part of what people look for now when sourcing an MRP/ERP system, because when they operate effectively, they can allow users to see live Work in Progress (WIP) at all times, which operations are in progress and who’s operating on them, as well as perform ‘what-if’ analysis on customer jobs before taking them on, so they can see the effect it will have on their shopfloor, and provide highly accurate deadlines.

Making it work requires a few things to come together. As a minimum, users need an MRP/ERP system in place to store the information for jobs and operations. They need shop floor data capture to get visibility of which machines are being operated on, when and by whom. And they need a scheduling package, which brings that information together to plan in jobs so they can effectively manage their resources in terms of which operators are available & when, if they have holidays coming up and which machines are in use. And then a live link between these three systems can mean that they are always updating each other with the latest information to give a clear picture of what’s really happening on the shopfloor in real-time.

The next level is to integrate plant as well. So, integrating Overall Equipment Effectiveness (OEE) data, using sensors from machines. It’s the next level of plant resource utilisation; understanding which machines are at capacity, and which machines need scheduled maintenance performed before they break down and cause real disruption.

This all leads to having great utilisation of resources, getting the most out of what companies already have to be able to complete more jobs, win more work, and improve productivity. So, I think these scheduling and management tools are incredibly valuable.

Q) How do you combat the natural anxiety for staff not used to using these systems or transferring to a new system after they have become familiar with an old one? How does training and the software’ s own interface and ease of use help, particularly for SMEs?

In any business, technology is only one part of it. Businesses comprise of people, process and technology to make up the total. And that’s true of software implementation or system changes as well.

The real key to these changes being successful is communication. It’s natural for employees to feel anxiety with any change, but effective communication can reduce that anxiety.

Firstly, the company needs to be led by strong leadership, with clear objectives and strategy that is effectively communicated, so that when the decision is taken to adopt a new system, it’s part of a strategy and a vision for where the company is going that everyone has bought into.

It’s important to identify the key people that will be involved in actually delivering the project and getting them involved as soon as possible, maybe even in the decision making process, as these will be the people most affected by the change in terms of their time, their role, and needing to work with others closely on the change process.

It’s important to be upfront with all staff about what will be involved, the potential outcomes and what it will mean to them. Especially if it involves increasing workloads or decreasing workloads.

The way we manage the implementation process is to have a kick off meeting, with all the relevant people. The key decision makers, and those people who will be most affected by the change – this will include outlining the project goals, governance, and some initial training.

Then, we create and agree a project charter. This really cements the commitment and is the ‘go-to’ document for understanding the success of the project. It clarifies everyone’s roles and responsibilities, the expected timelines and dependencies, and who’s accountable for what with clear escalation paths for any risks or issues.

For the project itself we aim to maintain constant open lines of communication between us and the customer so we can be up-to-date on any risks or issues that might be occurring. We also provide digital systems such as training videos and help manuals for when new members are added to the team, to help them get up to speed.

Q) How do you support your customers after they have implemented these systems?

Lots of people think that adopting a system and being trained – all the implementation and work leading up to the ‘go live’ is the hard part. That once they’re live, it is job done.

We believe that’s when the work really starts. We consider an implementation a success when the customer is seeing really value and ROI from the system. And that’s when all the system is fully integrated in their processes, their team are natural at using it, and it’s a routine part of the running their business.

Once our customers start making decisions using the data captured from the system that’s when we consider it a success - once they are using that information to innovate products, improve customer services, and feed continuous improvement initiatives. For our customers, we offer continuous, knowledgeable support throughout their use of the system, from people who understand the industry they work in, the business challenges being face, and the software they’re using. Our support teams and marketing teams feed directly into our product teams to ensure that we’re able to include best practices and real customer issues into the solutions we deliver – so the platform continuously evolves to meet customer requirements.

Q) Ultimately the returns must outweigh the cost but how is this measured and what feedback regarding this do you get back from your customers?

Calculating the ROI on an MRP/ERP system deployment is reasonably straightforward. A simple measure of a business’ productivity is Annual Revenue per Employee. Increasing annual revenue can be achieved by increasing utilisation and efficiency of resources (people and machines) through having the right data at the right place at the right time. Also, by removing manual steps from the process, which will reduce scrap and rework. All of which enables more work to move through the business and allows faster responses to market changes. This can all be done without the need to recruit more people, further driving up productivity of the business.

Q) How do you see these systems in the future integrating with Industry 4.0/ the Smart Factory, automation, robotics, additive manufacturing and AI?

We’re hearing it a lot lately about these advances, but adopting Industry 4.0 is a ‘journey’, by which I mean that companies can’t just jump to the end and implement automation, robotics and AI, without first preparing for the journey, and doing the beginning and middle.

Capturing reliable data efficiently, throughout your business is fundamental to adopting future 4IR technologies, and MRP/ERP systems are a critical part of the initial stage.

It is essentially the first step of digitalising your core processes by capturing data from people, plant and process throughout your factory. This gives you the intelligence needed to make informed decisions about further developments of your business. This then de-risks further investment in technologies and provides the foundation to enable things like automation, artificial intelligence or blockchain.

To be honest, without an MRP/ERP system in place, adopting those further technologies will not be possible.

(Q) How can you help smaller companies integrate all these systems and processes? How are you developing your software for the future to incorporate future changes?

It’s important to note that an ERP system no longer has to cost tens of thousands of pounds. They are a lot more accessible to smaller companies than ever before.

And for example, with Valuechain and Tricorn systems, we offer it through an SAAS model starting at £116/month, which is very affordable. It means that companies can get started easily and quickly without too much cost or risk tied to initial adoption, and then they’re able to see returns quite quickly, which makes them more able to afford a system.

The other aspect is that companies can often find it difficult to select a system. Realistically, companies are making an investment in technology with an expectancy that they will improve. It improves their processes, which can improve their product and service offerings, which can help them win more work, and scale their business. After 10 years, they might need to look for another system and go through the whole implementation and change process again, that we’ve previously discussed, only on a larger scale with more people.

So, sometimes there’s a system that would suit what they need right now, but maybe in 3 years, it will not support what they need to use it for. The alternative is taking the option to adopt a system that’s too big for them currently, but will last longer.

We are in the great position of offering scalable solutions. So, we have companies that are 3 people, using a system, all the way up to Safran for example. And they’re ultimately using a similar core system which can be scaled to the company as it is today as well as tomorrow, and tailored to different industries. So we can really offer the best of both worlds, in a system that’s tailored to specific industries, but can stay with the business for a long time and scale with them.