Supporting your strategies

Carter Manufacturing reveals how it helps customers supply the very best bearings to their end-users, and the unique process the company follows for every sales enquiry - through to delivery of the product.

Established for over 20 years, Oxfordshire-based Carter Manufacturing is acknowledged as one of the leading global suppliers of precision bearings and tooling equipment. Being sole distribution agents for several high-end specialist bearing manufacturers, including Carter Inc., Silverthin Bearings, KMS Bearings and UNASIS Bearings & Tools, underlines its status as being the ‘go to’ company for many clients across the UK, Europe, the Americas and beyond. So, just who is Carter and how does the process work?

“As a global supplier of precision bearings and tooling equipment, Carter has significantly expanded its operation and facilities over the past five years,” begins Carter Manufacturing’s chief operating officer, Melvin Meader. “For example, setting up distribution centres in Minnesota, US and Valencia, Spain, as well as implementing an engineering team dedicated to supporting customers in their selection of the correct bearing or tool for their application.

“This dedicated approach to every enquiry we receive starts from the basic question: is our ‘standard product’ the best solution for the customer? If the answer is yes, we can progress by quoting a product part number supplied by the distributor/end-user and supply accordingly. If the application is more complex, we can deliver a more focused approach, which includes helping customers to select a more appropriate bearing to meet the demands of their application - and this is where we excel. Why? Because thanks to a very experienced technical sales team, backed up by industry specialists within our engineering resources, we can work with customers to define exactly which type of bearing or aerospace tool they require.

What does a typical Carter enquiry look like and how do you approach it?

According to the company’s business development manager, Francesca Kotulski: “Typically, we receive several sales enquiry types, some of which is where the customer knows what they want, for example a Carter Cam Follower. We keep stock of the entire imperial and metric ranges, so it’s purely a case of quoting the part and (hopefully) converting the order to be shipped on the same day.

“Some need further support, and on most occasions our technical sales staff can assist. However, with others (recently we’ve seen a high influx of enquiries for our Silverthin thin section bearings required for space applications) is where we can engage our in-house engineering team.”

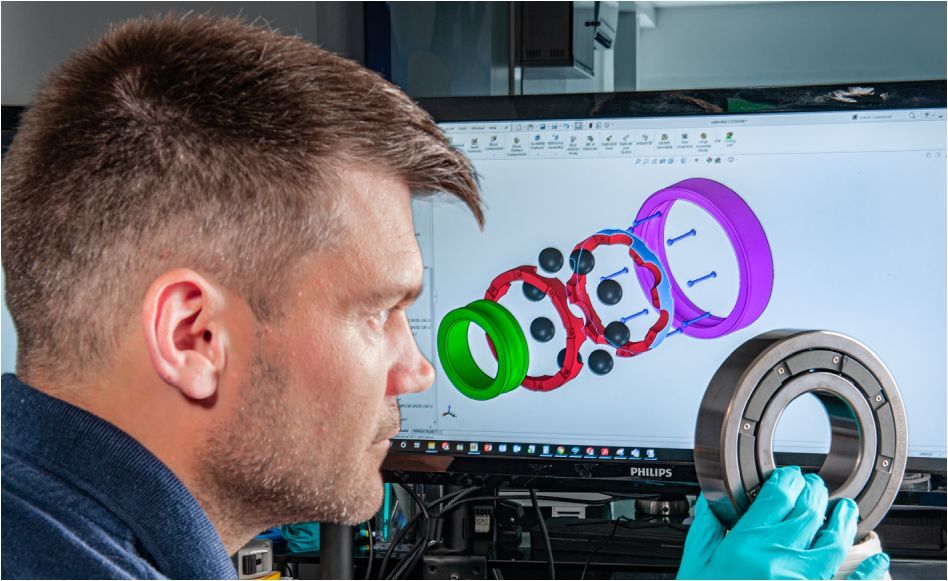

A bearing on design

Carter Manufacturing’s senior engineer, Ben Roberts explains how the company responds to the more challenging sales enquiries, and how it progresses enquiries from infancy through to recommending an appropriate bearing solution.

“Enquires can vary significantly in how fully the specification is defined, but despite these complexities, Carter is able to work with customers that have an initial concept, right through to customers that already have a fully defined bearings specification,” he explains. “Space applications present varying challenges for our Silverthin Thin Section bearings, which is why Carter prefer involvement at the early stages of design as it enables us to impart our expertise and knowledge, often allowing our customers to reduce design time, risk and cost. Many of the demands we see are similar across many applications, and this allows us to advise all our customers based on previous knowledge and experience.”

Once Carter’s bearings have been qualified through its engineering team, it’s time for the quality team to get involved. Mark Thomas heads up quality and compliance at Carter. He says the way Carter implements its ISO 9001:2015 and AS9120 accreditation ensures full traceability for all its products.

“The quality and compliance team review the customers’ quality management system (QMS) at pre-planned intervals to ensure that the bearings being specified continue to match the application. This includes the suitability, the adequacy and effectiveness in relation to each customer’s strategic direction and organisation, including their individual sites.

“Senior management is kept informed of all the key requirements, including all the necessary reviews which are essential in meeting ISO 9001 and AS9120 standards. The motivation and format of the management review has and always will be, to look at the strategies and business plan to ensure it adheres to the company ethos of delivering a quality product to the customer, on time and in full.”

Honing the knowledge

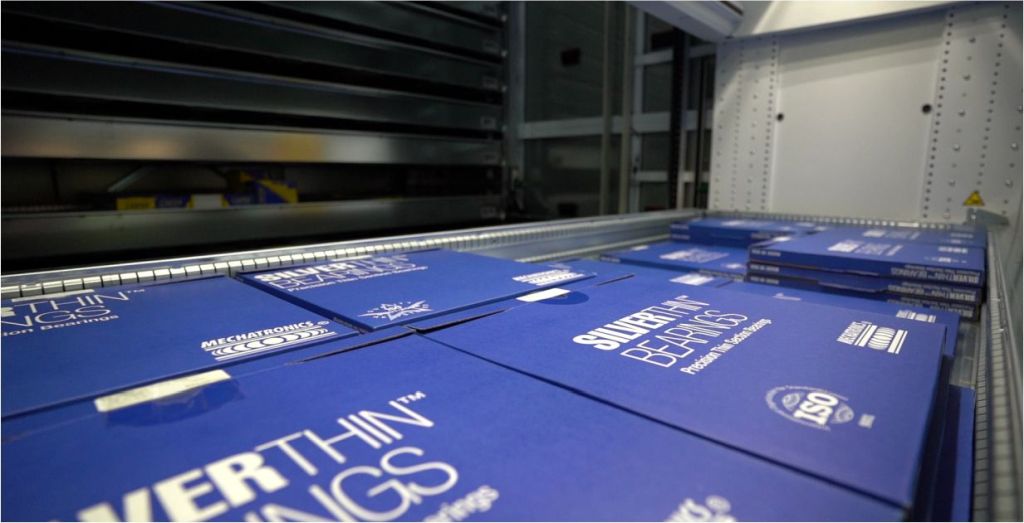

The final step on the journey is getting Carter’s product to the customer. As a multi-site international organisation, over the years Carter has honed its knowledge regarding international shipping requirements. This is crucial as it ensures that its products are delivered as quickly as possible, arriving in as good a shape as they left the factory.

Trevor Buckell, warehouse controller explains the process: “Carter Manufacturing keep large stockholdings of Silverthin Thin Section Bearings, Carter Cam Followers and UNASIS Specialist Bearings in multiple warehouse locations, which means transactions can be shipped from stock on the same day as the order is received. We can also ship bearings between companies to be dispatched from your local office within 24 hours and most importantly, having facilities in Valencia and Minnesota has increased our global supply chain capability, putting us closer to customers.”

With regards to handling the specialist bearings being made to order, Buckell reckons the process is, in some respects, easier.

“Our branded partner will send directly to the local office where we have team members who have been thoroughly trained in how to control documentation ensuring traceability is not lost. All documents are sent back to and stored at our central operation hub at our UK headquarters, so if anything is needed further down the line, we don’t have to go too far to reproduce it.”

In terms of focusing on Carter’s relationships with its customers, Meader says that the company’s relationships with suppliers, distribution partners and end-users is vital.

“There is a real culture of care here at Carter which is infectious,” he concludes. “We will always strive to go above and beyond and really make the experience of buying bearings through Carter as simple and pleasurable as possible. As we continue to grow, I can only see the relationships between the team members and of course our customers, becoming even more established and refined, which ultimately improves the sales cycle and enhances the customer experience.”