Taking a shine to laser projection

In a Q&A session, Virtek Vision’s CEO, Dietmar Wennemer reveals how the company’s laser projection solutions helps rapidly improve aerospace part production.

Processes such as cutting, placement and lay-up on mould tooling can add substantial time to the production of carbon composite parts in aerospace applications, particularly when dealing with large structures such as wings.

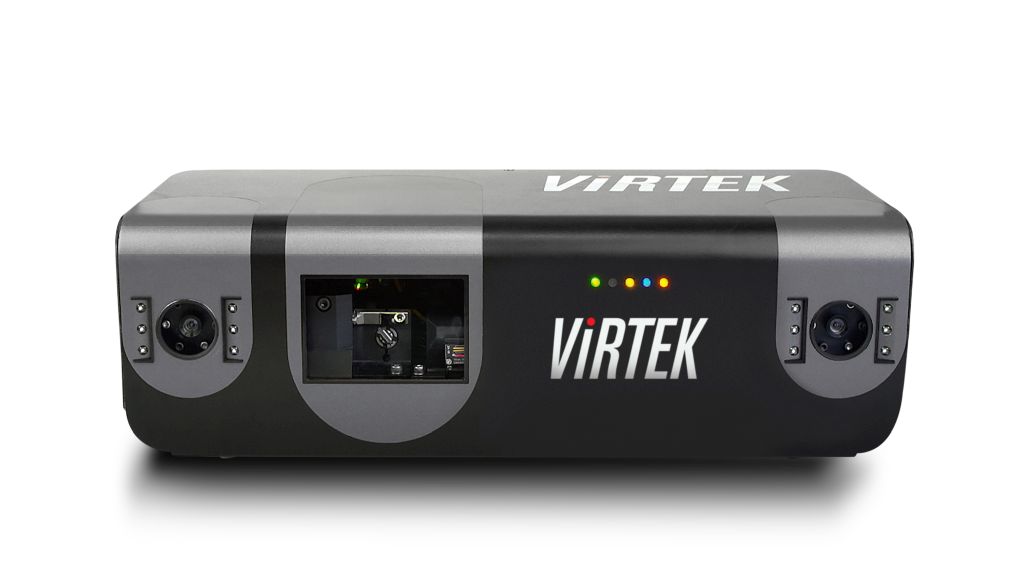

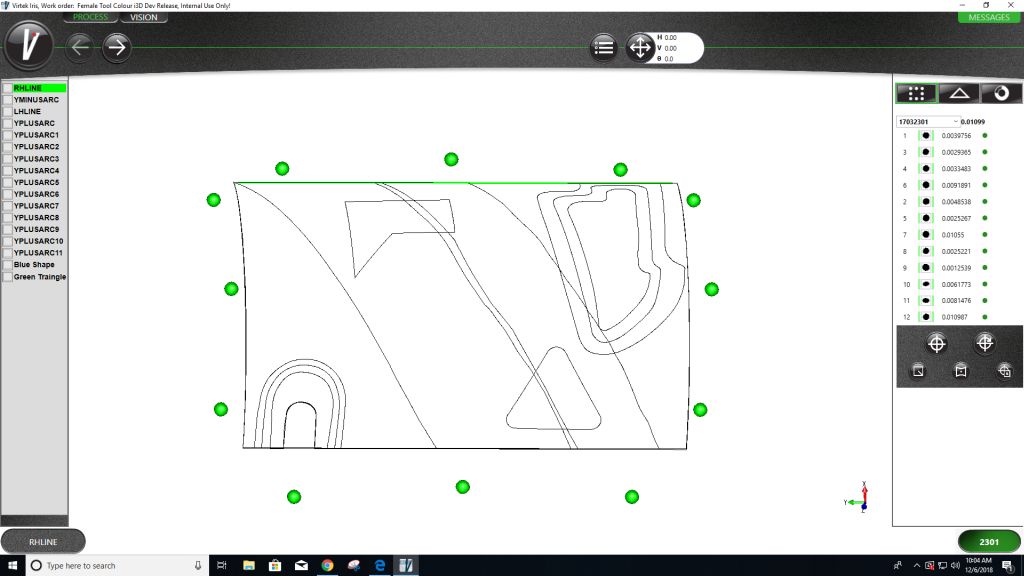

Virtek’s Iris software platform along with the Vision Positioning System (VPS) enables operators to construct composite parts without the use of bulky physical templates that have to be manually lifted on and off the mould while ply material is fixed in place. The system projects a laser outline of the part or material to easily guide the operator.

Virtek Vision was part of Gerber Technology until May 2021 and is now a PE-owned standalone company again. The company continues to innovate in the laser projection and inspection field, adding new specialised engineering teams that are working on new technology for its customers to help them accomplish their Industry 4.0 goals. Virtek recently upgraded its facilities at Canadian Headquarters in Waterloo, Ontario and invested in its Virtek Vision brand as a standalone company.

Q) What are the types of demands placed on your company by today’s aerospace designers?

Virtek has a strong connection in the aerospace world and we always offer the personal touch and excellent customer service. Our continuous innovation in technology and collaborative partnering approach has been setting the standard in aerospace for years.

Nowadays we see the ability to deliver, and flexibility on lead-time a big challenge as global supply chains became stretched and challenged us too. We were able to build up buffer stock for our customers and didn’t disappoint them, but it remains a big challenge for the coming years.

Q) Primarily, what are your laser projection products used for?

Virtek Vision has inspection and process compliance capabilities integrated into its systems. Our VPS integrated stereo camera system, which features our patented FlashAlign and our auto focus capabilities are proving very useful in the aerospace industry for ply overlay and assembly. It provides great flexibility, precision and re-alignment speed that our customers need for moving tools or tall ply layups.

Q) What are the chief benefits of laser projectors over traditional physical templates and hard tooling?

Virtek has an integrated SW system that allows for fast engineering changes and work order management. Our systems are digital integrated and can be driven out of the engineering CAD system without human interaction as a fully integrated automated process. Additionally, our high visibility laser projectors are standard, and are best-in-class at providing a brighter safe laser delivering superior visibility even in the brightest work environments - without requiring laser safety officers, or eye wear protection.

Physical templates are costly and have long lead-times, especially in today’s supply constrained world. Storage and management of physical templates is labour-intensive and requires qualified personal what is more and more difficult to find.

Q) Is there any restriction concerning the size of aerospace components? What levels of accuracy and size do your laser projectors offer?

Virtek’s vision systems have no problem projecting over very large areas. Indeed, we have some installations that cover over 120m in length. We connect many projectors together into a single system or multiple systems to cover such large areas. The coverage of a single projector is related to the distance from the tool or part. Virtek’s long range projectors are capable of operating at the longest distances of any in the industry with offsets of up to and beyond 18m and of course, all while meeting our customers extreme accuracy requirements.

It’s always best to consult our Virtek sales team members, so we can understand your industry and application needs as we have multiple projection systems that provide flexibility to our clients’ challenges. As a standard accuracy: ± 0.38mm or better at a distance of 15’ over 4.6m x 4.6m area

Q) Can you project using different colours – all at the same time?

Virtek has the capability to project multiple different colours and we are the original patent holder for this technology, but we identified and confirmed over the last 35 years that the green laser wavelength to be the best visible and best suited for our applications. Red and yellow laser beams are difficult to see (visibility and contrast on certain material) and create challenges in real world applications.

The Virtek laser projectors are used on several surfaces and include wood, plywood, steel, aluminium, plastic in different finishes and types, CFRP and many others. Bright finishes in orange or yellow are an advantage to make the laser lines more visible.

Q) What differentiates your products from the competition?

Virtek is an innovator by its core and we push the technology limits - and will continue to do so. We are investing every year over 10% of our revenue into R&D and our customers benefit from that. We have unique capabilities that our competition cannot offer. The Virtek Long Range projectors, special feature sets, such as ActiveTrack and FlashAlign with our IRIS 3D software capabilities are unique and just a few of the features that set us apart. Reliability, high quality systems and ease of use are other key features for our customers and we always make sure to improve in these areas.

Q) Have your long-standing partnerships brought huge benefits, particularly as trusted relationships can lead to a better way forward for all?

Virtek has long-lasting partnerships – some of them are over 30 years old with customers, partners and even suppliers in multiple market segments. That shows how much we value our partners and it definitely has worked very well for us and them.

We developed applications specifically for our long-standing customers that made their workflow much easier and production processes faster, repeatable and created a higher quality product for them. Our suppliers helped us push the limits of technology and worked with us to develop components best suited for these applications. Our partners on the distribution and reseller side worked with us to integrate our systems into their technology and made it part of a better overall offering that helped solve our joint customer challenges.

Q) What developments if any do you foresee taking place in the laser projector sector?

There are some disruptive technologies on the horizon. The laser projection technology needs to evolve to prevent being replaced by other technologies that are cheaper, precise enough and more flexible. Virtek is well aware of these technologies and our Virtek InnovationLab prepares us for the future and how to react to these disruptive technologies. Our customers are guiding us into the next chapter of augmented laser projection and we are supporting their direction.

Q) Finally, any other business?

A big thank you to our customers, partners, and suppliers for all your support. Also, thank you to all Virtek employees worldwide who contributed to the success of the company over the last 35 years - we hope to continue that success for years to come. It is an honour to be part of the Virtek team.