Test, test and test again

QinetiQ’s technical manager, Dr Adrian Britton examines the value and role of test beds in military aircraft preparedness.

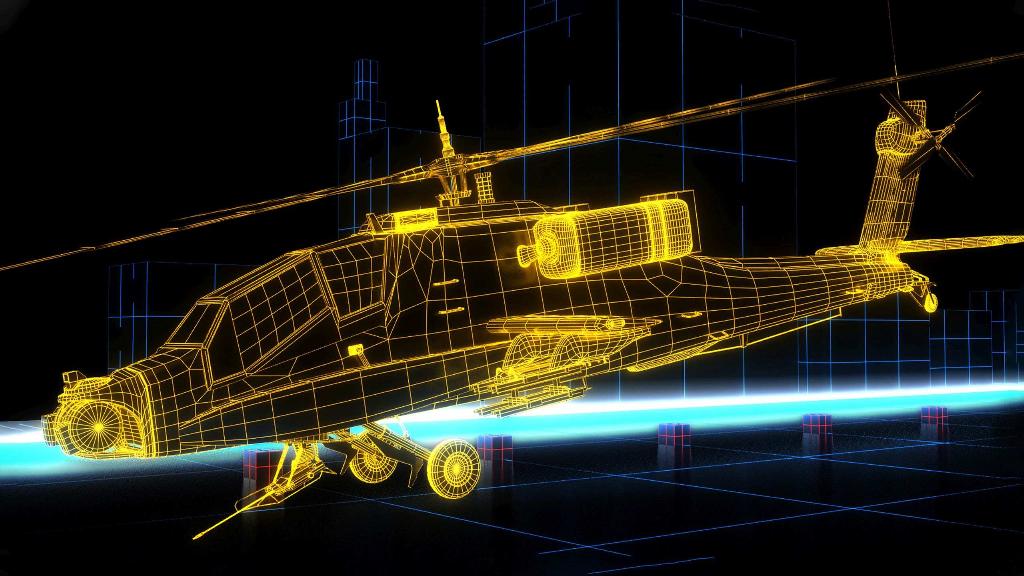

A modern Test & Evaluation (T&E) enterprise allows militaries to rapidly and safely experiment with new technologies and processes. This, in turn, enables them to evolve and create new defence capabilities to counter emerging threats and get new technology and systems into the hands of war-fighters faster. A key tool within the T&E regime is a test bed within which to qualify system integration, deliver spiral upgrades and conduct rapid systems experimentation.

The test bed can be used to represent the combat system of an aircraft’s sensors, weapons and defensive aid suites. Test beds can also bring together complex weapons and/or communication systems. A representative test bed is a safe and cost-effective place to evaluate changes without direct exposure to front line platforms and systems where the risks may be higher and the need for stakeholder assurances much greater.

Through appropriate management and treatment, safe and secure testing can be conducted in a test bed. Changes can be rapidly implemented and tested to explore options and inform further development. It is better, and more cost effective to find and resolve as many problems in the test bed rather than wait to deploy in a front line platform where additional costs, delays and assurances would be needed. However, there are inevitably some things that can only be tested on a front line system, within a truly realistic environment.

A test bed does not purely comprise all of the components that make the system; it sits within an appropriate test harness, typically a synthetic test environment, which allows a wide range of conditions, circumstances and events to be simulated. This helps lower costs and time periods compared to live trials in realistic conditions, and perhaps with live targets. Synthetic testing can be conducted relentlessly and repeatedly as the host system evolves and matures. A standardised set of system tests can be defined to enable baselining towards qualification. With increasing experience and evolving understanding, those baselining conditions can be progressively matured.

To fully understand the function, behaviour and performance within the test bed, various common tools provide the means to instrument and analyse the system in the test bed. These tools can measure and characterise the whole system and the impact of the changing component. These same tools can be further exploited to instrument and evaluate real systems and units operating in truly realistic conditions.

Holistic support

Sub-systems can be shared and sent to other suppliers for them to conduct system integration, driving cost and time integration across the whole enterprise. The test bed should be a resource for the customer, system integrator and the supply base and will be most effective if a single capability or facility can satisfy the needs of all to provide coherency and cost effective delivery. Policy, process and standards can be used to increase design understanding across the enterprise and minimise the need for T&E, however there is always scope for misunderstanding or errors for which undertaking T&E within a test bed is the important tool.

Test beds enable the customer to gain overall confidence and support accelerated qualification while the supplier can progressively evaluate and test a maturing product or component. This enables it to resolve uncertainties that cannot be assessed in isolation from the host system (such as within the factory). Within a mature enterprise, a collaborative and open-book approach should be adopted where the customer, system integrator and supply-chain see the outputs from a test bed and clearly show the cost and time benefits. The system-integrator can provide the customer with confidence in their platform and they can understand priorities and concerns from the customer. The customer can see how each of the evolving parts are progressing and how the whole of the system is evolving and maturing. The right commercial environment ensures that all parties are ‘safe’ and secure, whilst maximising collaboration for the customers’ end benefit.

Realistic environments

A well-designed test bed can also be used for wider testing with other test beds, or live units (such as in representative or realistic environments). By envisioning the test bed as being an interchangeable force component, it can be used to test or experiment within a real force, or provide a more controllable component within a force. This enables experimental capabilities to be evaluated in truly realistic conditions. By integrating the synthetic environment and the test capabilities for the live units, compelling and game-changing testing can be conducted to further drive time and cost out of demanding programmes using live, virtual and constructive (LVC) techniques down.

While typically designed and built to support the purposes of testing and integration, test beds can also be used for training and familiarisation. This enables tactics and doctrine to be explored and evaluated alongside the development of the component to ensure that overall usability is considered in any decision and poorer choices discounted as early and safely as possible.

As can be seen, the customer is empowered to build, test and operate a complex system, making the best possible decisions based upon an informed understanding of risk at the right time, thereby driving cost and time of programmes down. A test bed is a crucial tool in the T&E armoury for rapidly and safely introducing novel technologies into front line service. By evaluating and maturing a potentially complex programme of changes into a system or platform, timely and effective decisions can be made, maximising platform availability and utility for service.