Testing in the additive universe

As additive manufacturing finds applications across the aerospace industry, one thing remains a constant – testing continues to play an essential role in enabling the quality management of raw materials through to completed products.

The adoption of additive manufacturing (AM) as a viable means of production continues to increase, offering substantial advantages for the manufacture of low volume, high mix parts and complex geometries prohibitive under conventional techniques. As the scope of applications increases, demand for quality evaluations of key processes such as powder metallurgy also increases.

Physical testing enables quantitative analysis of supplier quality, adherence to procedures, and process performance. Maintaining quality in powder metal fabrication begins with the testing of the powders themselves. Metal powders are tested for correct chemistry, particle size distribution, and mechanical properties. Components manufactured by powder metal processes are typically tested for hardness, impact resistance, tensile strength, and density. AM part suppliers that develop the procedures to assess end-to-end quality position themselves effectively for growth. Consistency, reliability, and proof of performance represent integral elements for industry sectors with a low tolerance for risk, such as aerospace and automotive

Perfecting powder practices

Powder metallurgy is the foundation upon which AM parts are built. Assessing the integrity of raw material improves yield and directly impacts performance. Increasingly, AM part producers are performing their own particle characterisation tests, comparing the results with those specified on vendor certification documents. Testing of this type is typically undertaken as part of the inbound goods acceptance process. Shipments that pass inspection move into inventory with any lots that fail initiating follow up communications with vendors.

We are seeing growth in applications for additive manufacturing in the aerospace industry on both the production and maintenance sides of the sector. With the industry’s focus on material validation, it is essential that suppliers evaluate all aspects of quality, from the purity of raw materials to the mechanical performance of parts.

Delivering consistency

AM processes such as selective laser melting (SLM) offer outstanding creative freedom in design and thus, provide tremendous potential for lightweighting initiatives. A great deal of the foundational work with SLM technologies centres on lightweight parts for aerospace applications, where traditional manufacturing constraints, such as tooling and physical access to surfaces for machining, restrict the design of components.

In SLM, a 3D metal printer uses laser technology to fuse powdered metals into functional prototypes and end-use parts. The process involves deposition of each layer of material by melting sections of a bed of powder using a high-power density laser. After each layer, the powder is spread uniformly by a wiper and the process repeats, the melted particles fusing and solidifying to form a component, layer by layer.

SLM accurately forms complex geometries not possible with other metal manufacturing methods and enables builds to near-net or net shape, delivering cost-effective production of parts at relatively low volumes.

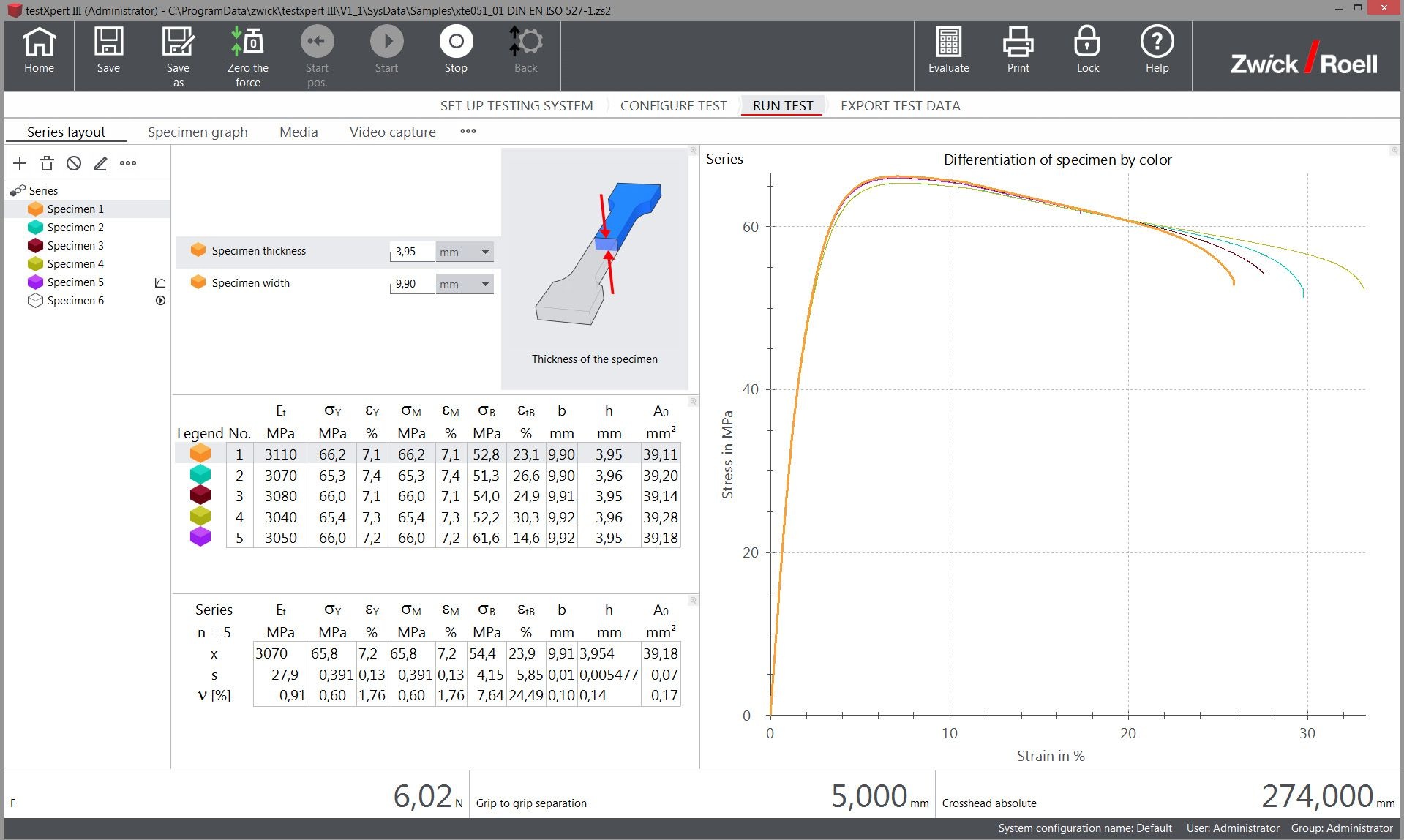

SLM Solutions is a global supplier of 3D metal printers that use the SLM manufacturing method. As with conventionally manufactured metallic components, parts produced via 3D metal printers must also be tested for their strength values. For this purpose, SLM Solutions uses a ZwickRoell ProLine 100kN testing system.

Delivering 3D metal printers that function with the highest levels of precision and repeatability is of the utmost importance to SLM Solutions. Characterising the material properties of parts produced with each system allows customers to ensure proper functionality. Materials testing plays a vital role in determining quality and functional integrity.

Part production through AM with a 3D metal printer may involve powder aluminium, tool steel, stainless steel, nickel-base alloys, cobalt-chrome or titanium. For each of these materials, process parameters must be separately identified and qualified. These parameters include, for example, laser power, scanning speed and coating thickness. To complete a parameter qualification, a tensile test is performed to check whether the new parameters reach or exceed the required mechanical characteristic values.

Ensuring performance

Conventional aerospace requirements involve strict validation of materials with qualification processes that can span 12-18 months or longer. Applications for space flight often have even more stringent requirements due to the extreme service conditions parts must endure.

Fuel tanks bearing liquid hydrogen deliver the propulsion needed for launch vehicles. Metal alloys used in such applications must be able to maintain mechanical performance under high loads and at temperatures in the -250°C to -280°C range.

Based in Garching, Germany, KRP Mechatec specialises in the development and analysis of materials and structures for the aerospace industry. KRP has established a test programme to explore the potential of AM for the lightweight construction of parts for launch vehicles. For this purpose, material samples are produced from the aluminium and titanium alloy-based parts produced via AM. The company uses a Zwick 250kN testing machine to conduct a variety of tests on the samples under non-ambient testing conditions.

KRP’s testing requirements resulted in the development of a special device that allows various tests ranging from tensile and compression to shear and hole expansion tests in a cryostat. In the cryostat, material samples are cooled to -196°C using liquid nitrogen or to -269°C using liquid helium and are then tested at these temperatures. Control of the required tests is achieved using the advanced ZwickRoell testControl in conjunction with testXpert III software.

High temperature testing

Intelligent user management in ZwickRoell’s testXpert III testing software reduces the number of required operator inputs, revealing only the options and information important to each user. Administrators retain full access privileges and the opportunity to control access levels based on roles and training levels. The software also logs all test and system relevant actions and settings, preserving a record for management review. This ensures traceable results that cannot be manipulated.

As AM continues to find applications across multiple industry sectors, one thing remains a constant – the need to validate performance of produced parts and components. Testing plays an essential role in AM, enabling quality management of raw materials through completed products.