Putting the theory of multitasking into practice

Toyo Matic Aerospace invited WFL to visit its factory in Brazil, where owner and CEO, Edvaldo da Rosa discusses the main reasons for purchasing a M120 MILLTURN/3,000mm.

Toyo Matic was founded in 1987 and initially focused on the renovation of machinery and equipment. Due to the lack of spare parts in the market, the company improved its machining techniques to meet its own needs. Around 1998, the telecommunications market was growing and an opportunity for change arose. Toyo Matic gained its first experience in the production of precision and serial parts. In 2001, the company entered the aerospace market, and during this time, opportunities have emerged in other industry segments, thus diversifying its activities.

Q: What is your company’s core competence, what kind of parts are you producing and what equipment do you have on site?

Toyo Matic’s 3-, 4- and 5-axis machining centres, lathes and multi-tasking machines constitute our vast fleet of machines and prove that investing in new features and technologies is a constant concern of Toyo Matic. Our competence is to always act fast and according to our customers’ needs. We want to exceed their expectations in meeting the deadlines and ensuring the quality of our products.

I would also like to underline the competence of our 70 employees. Our personnel management policy is about focusing on the training of our employees and taking their potential and individual capacities as a driving force for our company. We use AutoCAD, Solid Edge, NX (Unigraphics) and UNICAM to develop programs and projects. We also have CGTech Vericut software for programming, simulating and optimising processes.

Q: Why did Toyo choose the WFL multitasking machine and especially the M120 MILLTURN?

I have seen the machine at my customers’ site for the first time and was very impressed. Not only because of its variety, but also because of requests from my customers, I decided to buy one. Furthermore, the machine is perfect for manufacturing complex parts for the aerospace industry and the technical data perfectly fits the production of our customers’ workpieces. The M120 MILLTURN allows for one-hit machining of complex work pieces with a length up to 12,000mm and swing diameters up to 1,140mm. We also bought an M80 MILLTURN for the manufacturing of longer parts and for making deep holes, especially for workpieces used in the oil and gas industry. Unfortunately, the oil and gas industry is not yet in a very good situation. However, we are still hoping to receive an order from a customer in the near future. Perhaps we will use the M80 to manufacture parts for the aerospace industry as well. As flexibility is one of the machine’s key characteristics, we can use it for machining a huge range of different components.

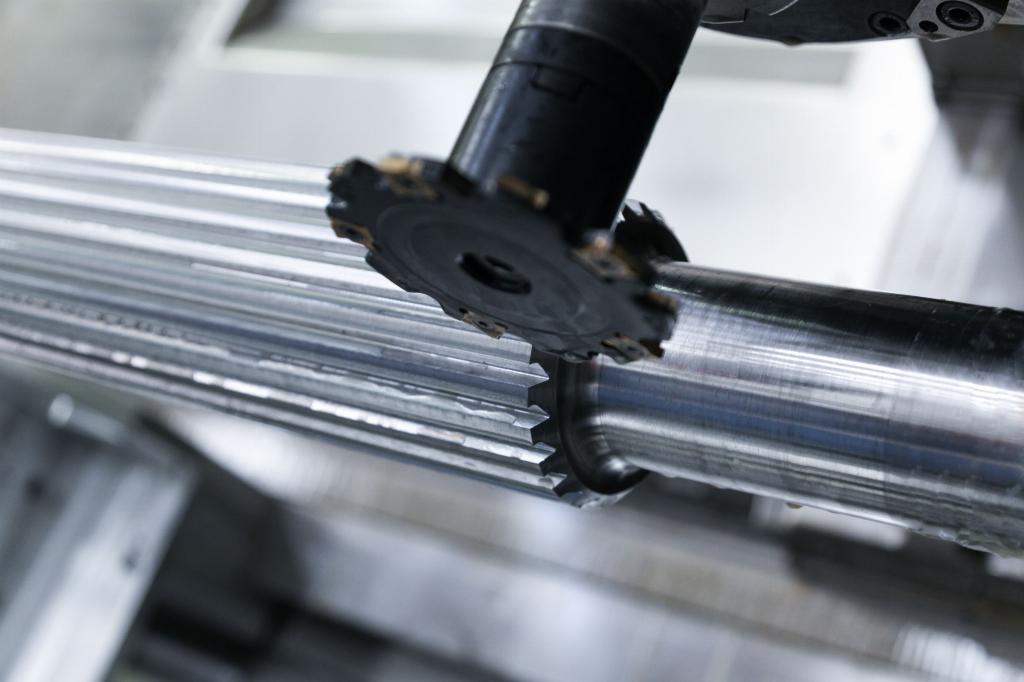

Q: What kind of work pieces are you producing on the M120 MILLTURN/3,000mm at the moment?

We purchased the machine because of an order from an aerospace industry European customer. They are producing helicopter parts and more precisely rotor shafts. The main reason for buying a MILLTURN multitasking centre was the high quality of the machined workpieces.

Q: Regarding service and support: have you always been satisfied with WFL’s services?

We never had any problems, so for this reason, I can’t say anything about the promptness of WFL services. It has been working in a ‘plug and play’ mode so far, as no incidents have occurred.

Only when we first installed the machine, we had some alerts for approximately 1-2 weeks. However, the WFL service acted very fast and we have been satisfied. That WFL has a service team here in Brazil is great, of course.

Q: What do you think about the advantages related to the multitasking functions of the MILLTURNS? Would you please name some key facts about the multitasking idea and what is important for you?

The main reason why we bought this kind of machine was the better ability to prevent mistakes. You can save time and even prevent errors, as you do not need to move the part from one machine to another. When you have the suitable program for your part, the machine is almost able to work alone. ‘Complete machining’ is the key phrase: putting the part into the machine once and manufacturing it completely. The defined process and programme need to be perfect in advance, then machining in one clamping becomes reality.

Q: How many operators are working on the M120 MILLTURN at the moment?

We have 10 multitasking machines with two operators. We have many machines but not all of them are working at the same time. For this reason, the operators can care about their projects in a good way. Although we have many different machines with different control panels, our team is able to manage all the orders in a good way as they are well trained on diverse controls. If you dispose of good programs and processes from the beginning on, everything is done and the machine runs. Therefore, we are satisfied with MILLTURN multitasking.

Q: What are the strategic plans for Toyo Matic? What do you believe in?

We are ready to provide parts for the oil industry, but need to wait until the price is going up. Customers know what we are producing and doing and they reach out to us, when they need special parts. They know that we are able to deliver, that we are flexible and that we can provide the very work pieces and machining processes they need. If a customer has a difficult part, they know that we are the perfect partner and supplier. Brazil is still in a crisis, but from my point of view, things are getting better.

Q: Finally, what do you think about Industry 4.0? How common is that in Brazil right now? Please tell me your opinion about industry 4.0, predictive maintenance, communication between machines and so on.

I think the most important thing is that you have good machines, good processes and of course good people to get everything done. Good machines and equipment in general are really important, but what they are doing between each other or what data they generate, that’s still a future topic for us.

Nevertheless, automation is one of the topics I believe in. A topic where we still have potential and where processes are optimised. Last but not least, I can state that I don’t know the formula of success, but ‘customer is king’ is the most important thing for us.