Unlocking the potential of the future

In an exclusive Q&A interview, Tim Zeigler, strategic account manager at aerospace technology solutions provider, JPB Système, gives us his take on things from the perspective of his own company.

In an exclusive Q&A interview, Tim Zeigler, strategic account manager at aerospace technology solutions provider, JPB Système, gives us his take on things from the perspective of his own company.

Be it the constant need to anticipate and meet customer requirements, maintain pace with technological change, or dealing with other sudden unforeseen issues, operating in today’s aerospace sector can have its challenges for OEM suppliers.

Q) How have customer requirements and expectations changed in recent years?

Any customer strives to have a great supply chain that can meet their needs and expectations with on-time error-free deliveries. Better yet, these would be sourced from companies that provide innovate solutions that help them, as the customer, make better products.

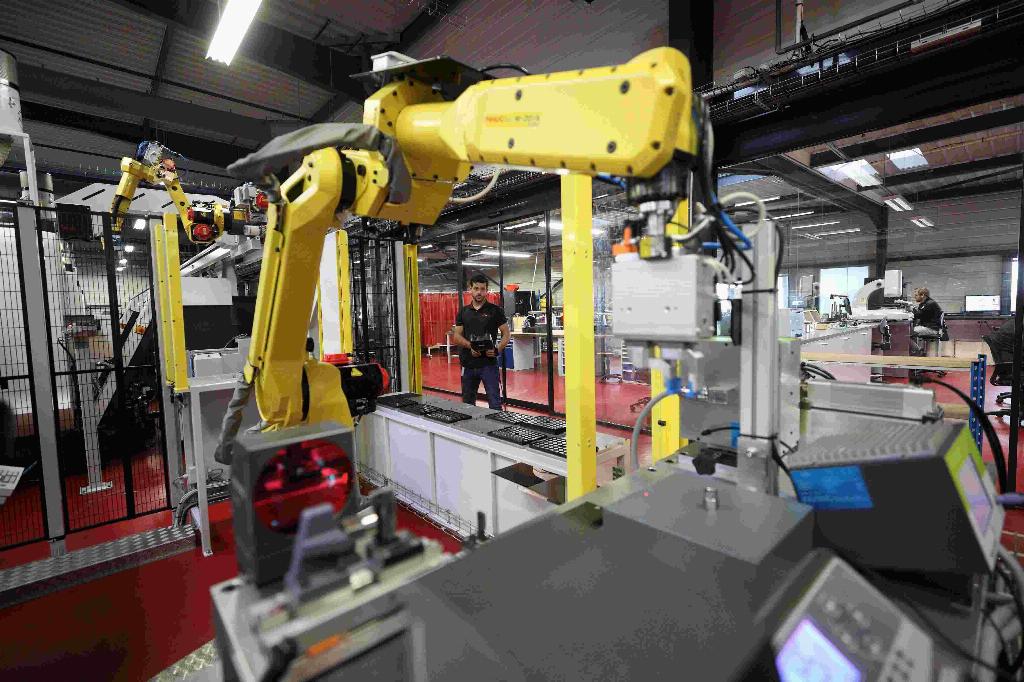

As a result, we’ve seen delivery schedules and customisation really increase, which in turn puts a lot more pressure on companies like JPB Système. With this in mind, we have invested to realise genuine Industry 4.0 manufacturing. Right now, I don’t believe that there are that many companies who are doing this. That’s to say installing the latest technology to bring about completely automated in-line production, where the machines can measure the part, make their own corrections, or even change tools – all the time ensuring the product adheres to the necessary quality requirements. Basically, I believe it’s imperative that companies adopt smarter manufacturing processes and technologies in order to stay competitive.

Q) How does the continued move towards Industry 4.0 and the Smart Factory concept influence your product development programme?

It is integral to us delivering solutions that meet the needs of customers. Those customers then have to assess the value of something that, during assembly and inspection, will allow them to test and ensure that parts are secure, accurate and performing to expectations – i.e. take preventative measures to avoid issues later.

The alternative is to spend potentially hundreds of thousands of dollars and many man hours to remove an engine once it has failed, strip it down, locate the problem, repair it, reassemble and re-install it on an aircraft. The value of the innovation that would have averted such an unwanted eventuality then becomes apparent.

Q) What are the key challenges faced by companies like JPB Système and what are you doing to overcome them?

One of the things we face is planned continual growth of around 33% or higher annually, which requires recruitment of talented individuals to operate within the modern smart technology-driven environment that I’ve described. Our senior managers regularly visit schools and universities, or arrange visits to our facilities, to raise interest and inspire students to consider a career in this industry. In addition, we work closely with undergraduate engineering institutions and second-chance schools to offer internship opportunities. Our site in Poland is also strategically located to tap into a pool of highly-skilled labour that offers us additional capacity to supply a mirror image, Industry 4.0 manufacturing and R&D site.

Another challenge for companies like ours is to stay ahead of the curve in meeting customer needs. As far as JPB Système is concerned, we inject 10-15% of our net income back into R&D. We regularly reach out to customers and prospects to offer engineering consultation via things like ‘lunch and learn’ sessions, in which we go in and meet with engineers to discuss issues they have, brainstorm ideas and develop specific innovations to address them.

Q) Achieving an annual growth rate of 33% is impressive. To what do you attribute this and how have you maintained your position within the industry?

I think it goes back to the first generation of our lockwireless products which were introduced as an innovative and cost-effective safety improvement that met the needs of our major OEMs. From that early juncture in our company, this gave us an opportunity to create solid relationships with OEM engineers and quickly gain their respect and trust as a solutions provider.

Subsequently, as we evolved our existing products and developed new ones, we found that customers were very receptive to what we had to say. Also, the pace of development within JPB Système has remained in step with that of customers, which enables us to offer solutions that we have had invented then fine-tune and deploy them together on engines or body structures.

Q) How do you maintain supply chain efficiencies?

Firstly, having the mirror-image sites in both France and Poland, with exactly the same Industry 4.0 processes, ensures that – if necessary – one site can support increased capacity demands from the other. We also purposely located our Polish site is amongst a heavy base of aerospace companies, so we’re able to ensure low-cost error free solutions to customers in very close proximity to that facility.

Additionally, for outside vendors, we have dual source back-up in the event of any supply issues, and beyond that, for non-critical parts we also have long-standing tertiary suppliers through whom we can obtain the necessary items.

Q) What are the biggest changes that you’ve seen within the industry in the last ten years?

One of the main things I’ve noticed is the way in which the supply chain often struggles to keep up with OEM demands based on technological advancements and requirements for smart technology within aircraft. The evolution of software systems and advanced avionics are some of the biggest developments we’ve seen in recent years.

To meet pace of change with materials innovation requires more advanced machinery and higher automation. A lot of companies don’t have the financial capital to invest, so it’s often difficult for them to maintain pace with technological innovation and to meet requirements further down the chain.

We’re also seeing the continued impact of newer technologies that run alongside or, in some applications, replace traditional manufacturing – a good example being 3D printing/additive manufacturing. Of course, if it’s the manufacture of a flight-critical part, it’s taken into much higher consideration. One of the current issues with turbines is that companies are still trying to prove, specify and research the material to see if it will withstand the conditions that a forged or bar stock material can already do.

Also, whether its commercial or military, aerospace companies are investing a tremendous amount of money to update ageing fleets. This has given rise to innovate new systems and engines that reduce noise and increase fuel efficiency – in the case of the latter by up to 20-35%.

Q) Finally, looking to the future, do you see opportunities to extend your solutions offering beyond aerospace to other sectors?

Absolutely, but we are also still extending our reach in aerospace, for example within aircraft operating systems, such as landing gear and hydraulic or pneumatic systems.

Beyond that, we’re looking at other sectors in which some of our core products like our borescope plugs and Lulylok self-locking fitting would be relevant. For these two solutions in particular, we’re seeing interest within the energy market, for example among manufacturers of engine turbines for power generation. Also, in time, I think there are key areas of the mobility sector, such as rail, where rolling stock operators may have a need for our solutions, but this is still some way off.