Exact Metrology helps customer in retrofit aircraft project

Metrology services provider, Exact Metrology says it has helped Chicago Jet Group complete a retrofit laser scanning job using a 85 series Hexagon Romer Absolute Arm.

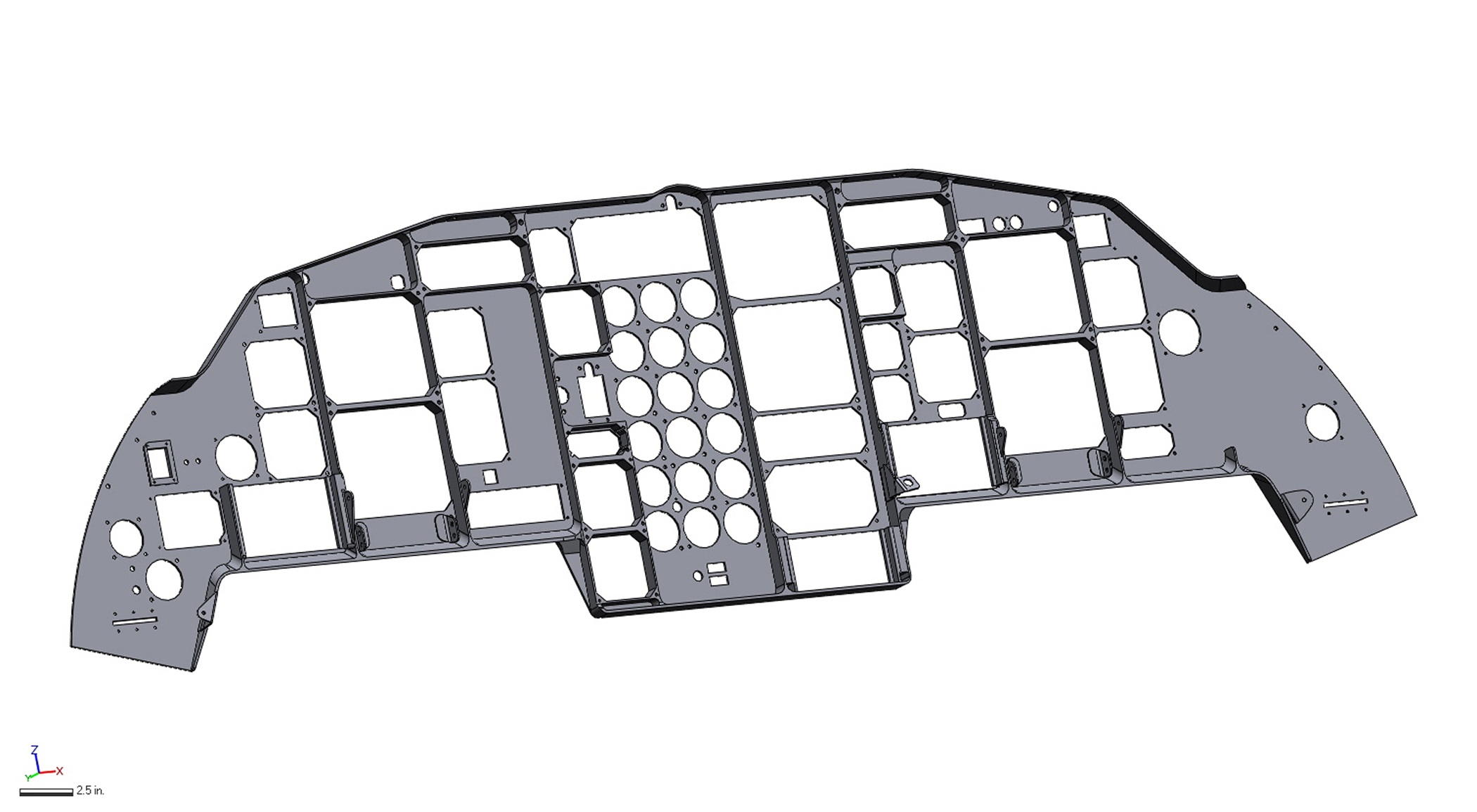

Chicago Jet Group specialises in aircraft acquisition, aircraft management, charter services, pre-purchase evaluation, aircraft avionics, aircraft consulting and aircraft maintenance. The company was retrofitting older Dassault Falcons avionics and needed a CAD model of the panel to see how it would fit.

Joe van der Sanden, application engineer from Exact Metrology, scanned the panel with an 85 series Hexagon Romer Absolute Arm. The Absolute Arm 7-axis delivers tactile probing and laser scanning in an ergonomic package. It is the best choice for ease of movement and ease of measurement. The flagship RS5 laser scanner offers high-speed 3D scanning for surfaces and features on a wide range of finishes and materials with less investment than the RS6. Furthermore, the RS5 laser scanner boasts a wide and horizontally-oriented laser scan line and fully-automatic exposure settings, making general purpose scanning functionality simple to apply regardless of application.

In addition, with mid-range width at 115mm, the laser scanner line of the RS5 makes digitising large surfaces simple and quick. The RS5 can be easily removed from the arm, allowing simpler and safer access to touch probing functionality in hard-to-reach areas. Thanks to repeatable mounting, it can be remounted without recalibration. Through the on-wrist OLED display screen of the Absolute Arm 7-axis, the RS5 allows for measurement feedback and settings adjustment at the point of measurement for a clear improvement to workflow productivity.

Then, dimensions were obtained in Polyworks Inspector. The Polyworks software suite covers the complete product development cycle, from part and tool design and prototyping down to final inspection of assembled parts. Polyworks Inspector is the industry-standard toolbox for product engineering, assembly guidance and final inspection.

Reverse engineering was performed using Geomagic Design X. This software combines history-based CAD with 3D scan data processing and enables the creation of feature-based, editable solid models compatible with existing CAD software. Geomagic Design X allows users to re-use existing designs without having to manually update old drawings or re-measure and rebuild a model in CAD. This software is easy to learn and use, for it uses familiar history-based tools found in all major CAD products.

Chicago Jet Group was very pleased with the work performed by Exact Metrology and they would be happy to work with them again. A senior avionics technician at the company said: “This will save us months of measuring and drafting.”