Faster titanium machining

Dörries Scharmann Technologie joins forces with precision tool specialist, Walter to obtain optimum results when machining titanium components.

Titanium is in vogue, at least in the aerospace industry where every gram counts. The properties of this light metal are ideal, particularly when combined with carbon fibre-reinforced plastics.

Titanium’s hardness, toughness and low thermal conductivity make machining it a challenge. Dörries Scharmann Technologie (DST) has assembled a machine tool package for this purpose in collaboration with cutting tool manufacturer Walter.

The collaboration goes far beyond the supply of tools. Jürgen Senger, Walter’s field service employee provides some examples: “We run training sessions at DST, work closely with the programming department and have been doing more and more project work together since 2012.”

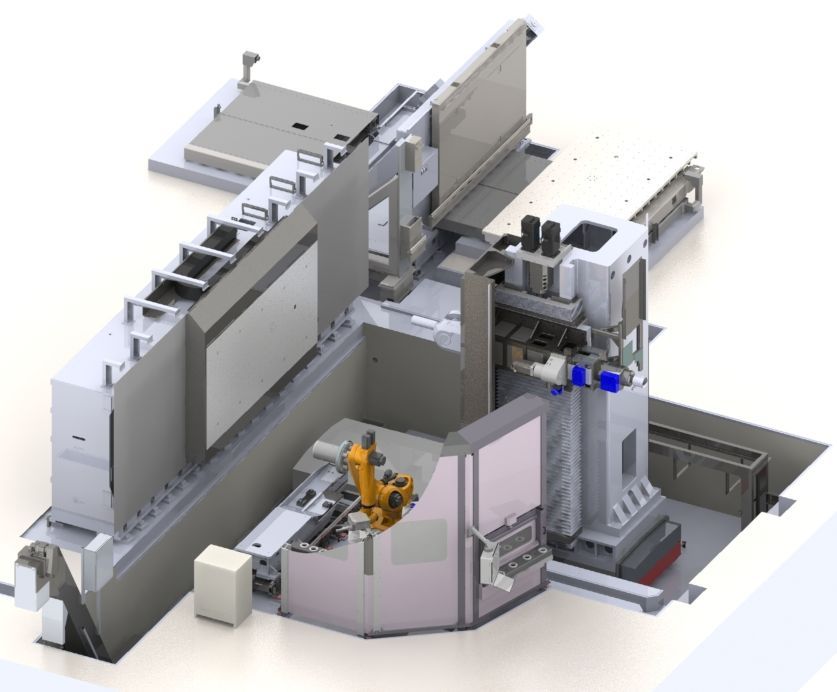

The latest venture involves tools for the new ECOFORCE Ti machine for machining titanium. Thomas Troup, DST’s head of applications development says: “Our collaboration is characterised by professionalism; we can rely on one another and we have created an atmosphere of mutual trust.”

DST enjoys an excellent reputation with aircraft manufacturers. A walk through the production halls in Mönchengladbach soon makes the reason clear: the size of the machines is indicative of the huge dimensions of the structural components they produce. With its ECOSPEED series of machining equipment, DST has established itself as one of the world’s leading suppliers in the field of machining high tensile structural components made of aluminium. High levels of productivity are vital.

For some structural components, up to 90% or more of the material is machined in order to produce a finished part with an optimised weight from a massive block of aluminium.

“The main advantages of our machining apparatus for aluminium are the high spindle power of 120kW available over a wide range of speeds, the high-dynamic parallel kinematics of our Sprint Z3 processing head, and the horizontal spindle arrangement,” explains Dr Marcus Queins, head of technology at DST.” As a result, the chips can fall away unhindered in a downwards direction. This is regarded as just as important for titanium, which is far more difficult to machine, as it is for aluminium, because repeatedly cutting through the chips causes the indexable inserts to wear out quickly. This is why we also configured the ECOFORCE Ti with a vertical pallet in the operating area, thus providing optimal chip clearance.”

The tough can get tougher

Machining titanium still depends more on torque than on cutting speed. However, the use of titanium is becoming quite common in parts of the aircraft manufacturing industry, so production engineers are taking increasing note of productivity. It is forecast that 85,000 tonnes of titanium will be machined worldwide by 2018, more than two thirds of it using indexable insert and solid carbide cutters.

Walter has responded with an entire range of specialised tools. One example is Walter’s M3255 porcupine cutter. In a test configuration, the D80 Z6 version (80mm diameter, six rows of teeth around the perimeter) machines 315cm³ per minute, at a cutting speed of 45m per minute and a feed rate of 0.15mm per tooth of Ti AMS 4928 titanium alloy. DST used this expertise when it tested the new series of machines.

Boeing was a pioneer of new materials with the 787 Dreamliner. However, the structural components are still made of non-ferrous metals. The problem is that the expansion coefficients of aluminium and CFRP differ considerably, which makes them very difficult to combine. On the other hand, the low expansion coefficient of titanium is similar to that of CFRP. In comparison with aluminium, it has a slightly higher specific weight, but despite this, some titanium components are even lighter than aluminium or even steel parts thanks to its much greater tensile strength. This is what impresses the aircraft manufacturer, for whom every gram counts, and on the whole justifies the much higher price of the material. But this price has implications.

“Titanium components are increasing in complexity because the total weight of aircraft and therefore their fuel consumption can be improved only by optimising the weight and tensile strength of the superstructure,” says Dr Queins with reference to the first ECOFORCE Ti, which is now in the testing phase here.

The ECOFORCE Ti should meet the aerospace industry’s two requirements, namely higher machining rates and lower costs per part – without adversely affecting process reliability. The 5-axis machine has an automatic head-change system, which on the one hand can achieve very high torque of up to 5,500Nm and corresponding feed forces during 3-axis machining, but on the other can also undertake roughing and finishing operations with a compact fork milling head in 5-axis mode.

A machine like this can demonstrate its full performance potential only with tools suited to the machining process. According to Thomas Troup of DST: “The requirements define the limits of what is technically feasible at present and for that we need a coherent overall design. This is why we usually sell the machine and tools as a package.”

Walter adapted the tools for Ti machining to match the performance of the machine exactly. In tests, they determined the optimal machining parameters jointly with the DST developers.

This type of collaboration requires a partner “who thinks not in terms of tools, but in terms of technologies and integrated machining,” adds Troup. “The way development is shared between us, the machine builder, and the tool supplier varies greatly depending on whether priority is given to the behaviour of the machine or the tools, for instance if they have to be very slim in order to reach deep pockets on the part.”

The objective is an integrated solution which meets customer requirements, because turnkey technology packages seem to be in vogue for customers too.

Another important point in Walter’s favour is worldwide availability. As a rule, when end customers buy packages like this, they expect to be able to purchase replacement tools anywhere in the world at a later date. Walter can ensure that customers receive not only the tools on site, worldwide, but also fully support them, and as Senger points out: “We notify our colleagues on site to liaise with the end customer in advance so that they can also provide support immediately.”

Both sides gain

Both sides derive various benefits from this long-term collaboration. “DST has the most efficient machines in the marketplace,” says Senger. “We use these at Walter to test our latest developments. We currently have a whole range of special tools in use at DST which comes straight out of development.” In return, DST is always kept right up-to-date with the latest in tool development.

The project team has set itself ambitious targets for the future as Troup concludes: “We now have our sights set on one litre of titanium machining volume per minute, and I’m convinced that we can manage it together with Walter.”