Think yourself fitter

Looking for an intelligent way to make your factory fit? Then look no further. Mike Richardson starts his digital fitness transformation by discovering how Fitfactory is helping manufacturers work smarter to get lean, be more agile and more productive with modular scalable ERP systems.

So much has changed for Fitfactory since it launched its new brand, Fitfactory Technology, just over a year ago. When the pandemic struck, civil aerospace was hit hard and the needs of the market and its customers changed. As a result, the company took the opportunity to reflect on both itself and the products and services it delivers to the market.

“Over the last 5-10 years, we have identified that a clear gap has emerged between technology providers and manufacturing/engineering companies in terms of explaining the tangible benefits of digital,” begins Fitfactory Technology’s marketing director, Alex Knight. “For example, no-one talks about how that technology is going to reduce inefficiencies? What impact it will have on your order book? Will this help increase capacity? Even consultants and articles online discussing the benefits of digitalisation demonstrated examples of large assembly lines, which is difficult to translate for SMEs.

“When order books were shrinking and there was uncertainty in the market, it was difficult to justify a substantial new investment. However, digital technology could be a real lifeline to many companies. Some of our customers made the best use of resources and adapted quickly to changes, reducing the impact. And for others, they were able to pivot into different sectors, and they were attractive to new customers because they could demonstrate their previous performance and stability by showing their digital KPIs and responsiveness.

“So, there was this global challenge. We know that digital technology can help companies survive it, and a clear gap where no one seems to be explaining why it can help. Then here we are, with over 25 years of experience delivering digital technology to SMEs, and we want to bridge that gap and demonstrate the impact technology has and the ROI it creates. And that's what we focus on as Fitfactory.”

Knowledge is power

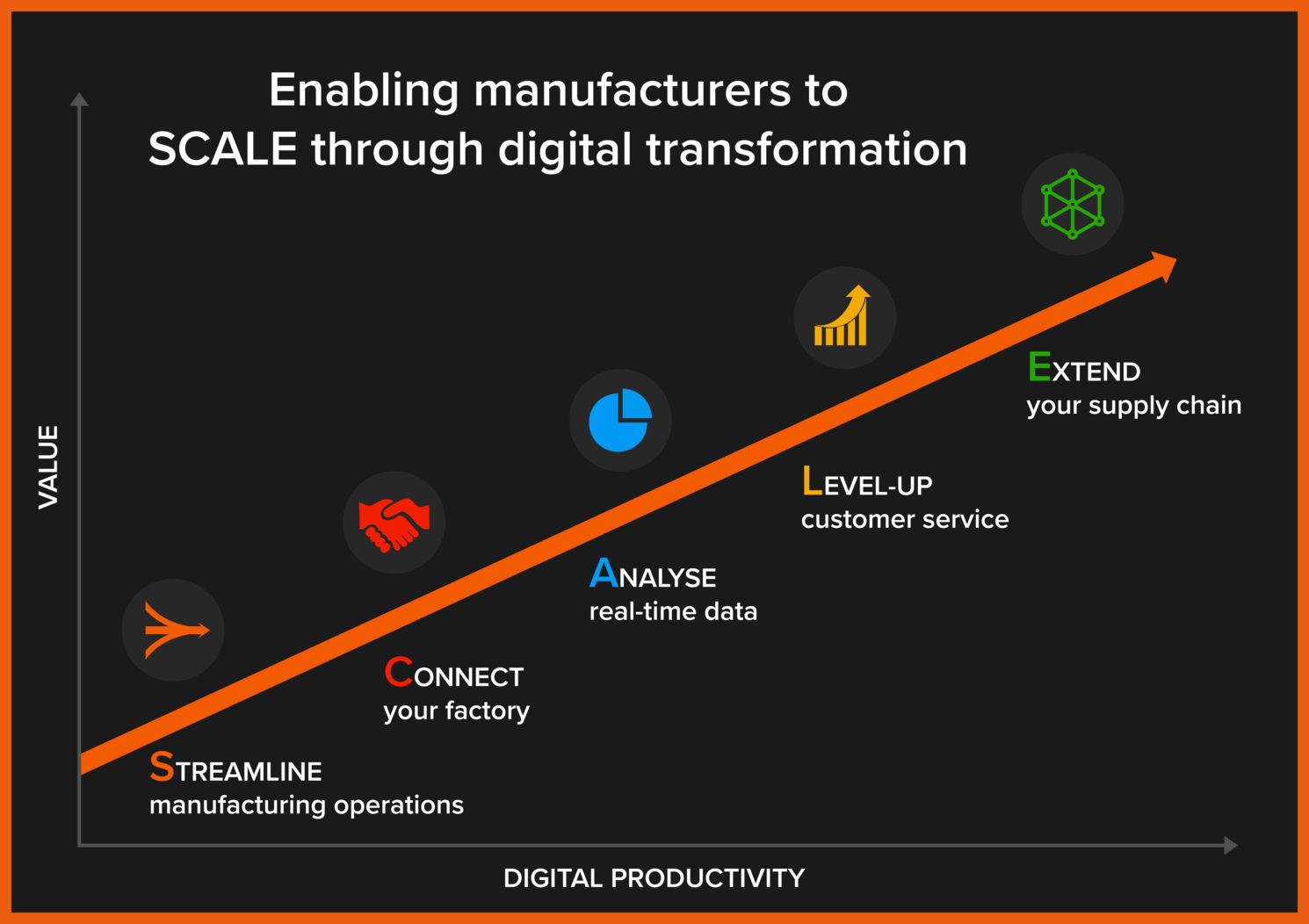

Knight says that enabling manufacturers to SCALE through Digital transformation is a shift in approach that has completely changed how the company works with businesses.

“With every new emerging technology, 100 new providers come with it offering their unique take – all of which potentially have a place in your factory. But with so many options available, the most important thing is strategy. How can you decide which one is right for you? Does it come down to cost? Do you create a list of requirements and compare options to that? Or have you considered the long-term goals of your business over the next 5-10 years?

“We always try to work with companies to understand their goals and identify the right solutions for what they need. Often, companies have adopted an MRP, CRM or Quality Management system that is best in class at the time. However, bottlenecks emerge after a few months or years because there is no way to efficiently exchange data between the systems. This results in using paper-based systems or spreadsheets, which adds the inefficiencies back into the process and opportunities for manual error. So, you're essentially negating the benefits you had in the first place.”

Fitfactory offers a modularised end-to-end digital transformation solution. This model gives companies the flexibility to take what they need, when they need it and know that Fitfactory can support future growth. Everything is integrated and easy to use and learn.

“We put this into our SCALE framework, which helps our customers create a roadmap for their digital journey: Streamline manufacturing operations through MRP and Scheduling software; Connect your factory across people, plant, products, processes & partners; Analyse real-time data to generate actionable insights and optimise performance; Level-up customer service by sharing real-time data upstream and downstream; Extend your supply chain ecosystem to increase resilience and mitigate risk.

“So, you really start with the foundations and incorporating digital processes before connecting disparate systems and automating the interconnectivity. Then you can analyse your business and get a complete view of everything because it's all brought in together. Next, you can level-up customer service by sharing all that information with customers and suppliers in real-time. Finally, you're ready to extend your ecosystem by engaging in collaborative networks. You can use your data to promote your business and utilise big data and predictive AI to identify high-quality new suppliers. So it's a really end-to-end approach to digitalisation.”

It pays to plan ahead

In terms of the specific areas in Fitfactory’s suite of modules, I’m interested to know which are proving most popular with the company’s customers?

“Scheduling and real-time shopfloor engagement are critical for our aerospace customers,” Knight continues. “Being able to plan, optimise resources, and have full traceability of shopfloor activities gives them the flexibility to adapt to changes in demand and operate leaner. As well as this, customer communication has become more important recently. As you couldn't do site visits for a few months, we became reliant on digital communication. And companies are now able to differentiate a lot more on how much visibility you give to your customer.

“Additionally, we are about to launch a new version of our business intelligence tool, Insights, that will allow companies to share a real-time dashboard with customers. These dashboards contain all the information about the job and previous quality, cost and delivery performance. Which is a real level-up in terms of the customer service you offer because instead of the customer sending an email or picking up the phone for an update, they can just log in and see it.”

Fitfactory says it is the leading software provider implementing the UK's first private 5G network in an SME with AE Aerospace.

“AE Aerospace has a clear vision of its goals over the next few years, where the company intends to be very data-driven and share real-time information with customers and suppliers. So, we were able to work with them to identify technology to help them achieve that. Additionally, working with BT, West Midlands 5G, Ericsson and Vision Intelligence, AE Aerospace is now able to utilise 5G to generate vast quantities of rich data from their whole shopfloor. Their entire operation is then connected and linked directly with our systems.”

Integrate to innovate

According to Knight, it is critical that an MRP or ERP system integrates with the new Industry 4.0 and smart factory technologies. Digital processes are the foundational step of Fitfactory’s SCALE model for digital transformation, because so much of industry 4.0 is dependent on data - and digital processes can generate much of the data and information you need.

“Suppose you consider a manual process, such as writing a letter and handing it to someone versus the digital alternative of writing an email and sending it to someone. Yes, digitally, it may be more efficient, it will probably have fewer mistakes thanks to the autocorrect, and it's even more environmentally friendly. However, the key benefit is that the email client also records a copy of the email; it records the time it was sent, who sent it, and who received it. In addition, if you use Mailchimp or an equivalent system, it also records how many times the recipient opened it, what time they opened it, and which links they clicked on it.

“So, you're not just making the process more efficient and more accurate, but you're capturing lots of data from the digital process as well. And that is so critical to creating the ‘Smart Factory’. Production control, MRP and ERP systems all do this, but the important next step is to integrate with external systems, machines, robots, and business intelligence systems. Capturing the information is essential, but you need to be able to use it. Your MRP could link with machines in your factory so that starting a CNC machine should signal to your MRP system that the operation has begun. Additionally, you should bring the information into a business intelligence system with your production data, quality management data, HR, sales, and finance to analyse business performance as a whole.”

This interconnectivity allows Fitfactory to differentiate itself from its competitors. Renowned for its MRP systems, Fitfactory’s wide breadth of software means it values how each system performs - and the integration between its systems.

“For example, in the Connect stage of our SCALE model, we aim to connect the 5Ps: ‘People, Plant, Processes, Products and Partners’ of your factory to automate information transfer between these parts and reduce departmental silos and fully connect your business,” Knight concludes. “Additionally, through our Insights platform, we enable companies to analyse all of their information together. In the tool, you’re not just pulling the two data sources onto the same platform, but you can merge the datasets and cross-analyse them. So, you can quickly identify the root cause of issues because everything is connected and presented together. And it's so easy to use.”

In essence, it ties together Fitfactory’s vision of bridging the gap between technology and industry by taking a customer-first approach, looking after the end-to-end digitalisation, and making its software easy to use.