It’s time to fall in line!

According to Jacquet Weston Engineering, a focus on successful surface finishing and treatment process line implementation can bring clear benefits to the aerospace sector. Aerospace Manufacturing reports.

Nick Weston, managing director of Jacquet Weston Engineering (JWE) believes that successful process line installation depends on a range of complementary factors.

“Improved operations, enhanced environmental performance, system versatility and quality control,” he begins. “The key requirements of surface finishing and treatment lines are clear-cut – and, in this context, the aerospace sector can be a prime beneficiary.”

Since the early 1970s, JWE has focused on the development of surface finishing systems that provide customers with a list of capabilities. These range from traditional installations, including zinc and zinc nickel, to specialist facilities, such as sulphuric, chromic, boric and hard anodising processes – all of which are central to aerospace manufacturing.

The breadth of manufacturers and suppliers who operate within the aerospace sector points towards the need for system versatility but, in all cases, fundamental considerations need to be accommodated. Consistency and repeatability are high on the list as is monitoring and traceability through data logging with Nadcap compliance – the importance of which needs little emphasis in this particular industry. Weston points out that these are principles that apply both to independent subcontractors and larger manufacturers who, he notes, are starting to take a fresh look at the installation of in-house process lines.

JWE believes that, in all cases, the design function plays an increasingly important role in system development. Before installation, the company is able to set out full, operational lines at its Newbury manufacturing plant to demonstrate a range of performance factors – from process control and handling operations to effluent management. However, it is the process before that which, it believes is often key.

“We make full use of the latest versions of Autodesk and AutoCAD mechanical and Autodesk Inventor software to produce 3D drawings which help to create plant layouts and ‘fly-throughs’ that visualise operational procedures,” continues Weston. “Comprehensive and detailed maintenance instructions, including piping and instrumentation diagram assembly drawings with full Health & Safety compliance, and CE certification can then be produced.”

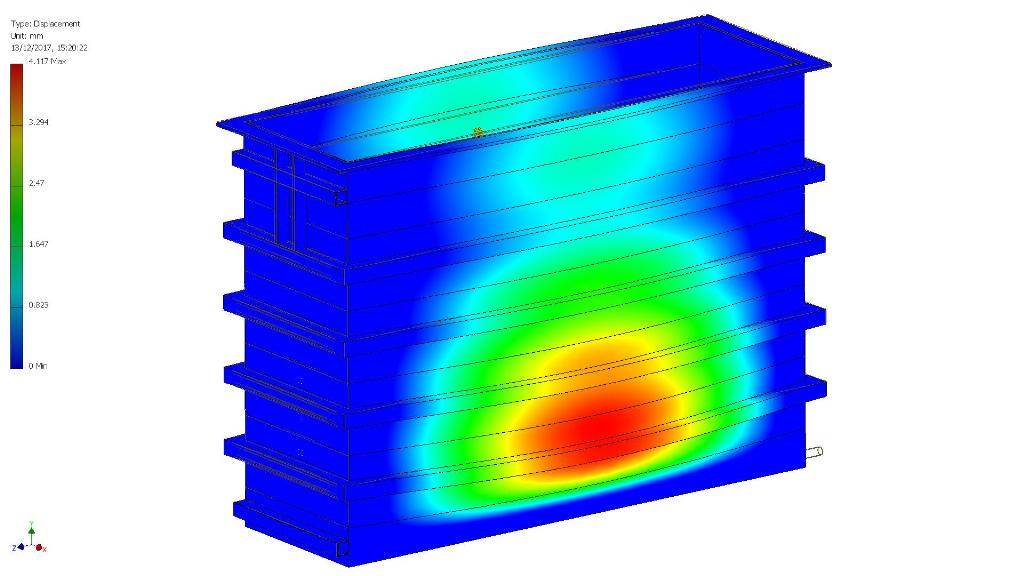

He points out the company’s 3D Inventor design facility also allows it to run FEA stress studies on all major components prior to manufacture. This ensures that they comply with the appropriate British and European standards and are central considerations in the aerospace industry.

Weston also highlights the fact that JWE is the only UK plant supplier in its sector with ISO 9001-2015, ISO 14001, ISO 18001 and JOSCAR approval, while also being members of key industry organisations, such as the Northwest Aerospace Alliance and the West of England Aerospace Forum.

The company believes that the move away from the use of chrome in process line facilities is a further consideration which the industry must address. In this regard, it draws attention to the increasing use of Tartaric Sulphuric Anodising (TSA) and boric anodising as evidence of this focus, with the methodology shown to provide surfaces that promote adhesion of paint on aluminium alloys, thereby increasing corrosion resistance.

The importance of making sure surface treatment operations are of the highest quality is important across all areas of manufacturing and, perhaps, it is of particular note in safety critical scenarios such as those associated with aerospace engineering. By ensuring a line is optimised from both an operational and environmental perspective, and that it interfaces efficiently with other production elements that can range from heat treatment and painting to metal spraying, it can offer key benefits across the board.

“Design, testing, installation and monitoring to meet predefined needs – while still retaining an important degree of versatility – are all fundamental and, we believe, form the basis for engineering production and performance success,” concludes Weston.