Leaping over the CAM programming hurdle

CloudNC tells Ed Hill about its revolutionary new CAM programming software CAM Assist aimed to dramatically reduce CNC machine tool CAM strategy creation.

When it comes to reducing machining time, unsurprisingly much of the focus is directed towards reducing cycle times on the CNC machine tool transforming the billet into the finished part - but how much time is spent before that in programming CAM strategies such as cutting toolpaths, speeds and feeds, and tool selection? Depending on the complexity of the part, even with the input of an experienced CAM programmer it can take a matter of hours or even days.

Now, however, one company is revolutionising this aspect of metal part production. CloudNC has developed its CAM Assist software to turn the programming process into a simple click of a mouse operation. And its developers say it is particularly suited for accelerating the time it takes to make parts in the aerospace sector.

The brainchild of CloudNC co-founder Theo Saville, CAM Assist is essentially a means of taking the convenience of making additive parts on a 3D printer and applying it to a machine tool.

“The CNC machine is fundamental to the manufacturing process,” he says. “Whether it’s mould & die production, tooling, fixtures or end use components, so much production can’t be achieved without it, so if you can speed up the process from receiving a CAD file to taking the finished part off the machine you can hugely increase productivity.”

Self-smart production

CloudNC says that by using CAM Assist, programming time can be reduced by as much as 80%. It works by using a combination of data-driven optimisation and artificial intelligence to produce machining strategies. The technology is more along the lines of a chess grandmaster-defeating supercomputer, than generative AI associated with large language models such as ChatGPT.

“CAM Assist first examines the thousands of ways the surface of a component could be machined,” continues Saville. “It then works out what are the most efficient and reduces them – finally selecting an optimum. At its core CAM Assist is like a machining technician. It has a practical understanding of the physics and processes of cutting metal so it can make the sort of decisions that a machinist would make.”

After CAM Assist has produced an initial cutting tool strategy an experienced CAM programmer can refine it further if required.

CloudNC can certainly prove the effectiveness of its software in production. When the company was established, it also built a state-of-the-art machine shop in the UK to manufacture subcontracted CNC machine-made parts using its software. All the data that is acquired on the shopfloor is inputted back into the CAM Assist programme as it is being developed by its software engineers.

The new programme is already attracting interest from the aerospace manufacturing sector, not surprisingly for a company that is able to name Lockheed Martin as one of its partner investors.

“Interest in us as an aerospace subcontractor has really accelerated because of the connection with our innovative software,” comments Mark Duke, chief operating officer for manufacturing at CloudNC. “Aerospace is the ideal sector to demonstrate its advantages because of the complexity of the parts, the certification standards required, lower volumes and diverse materials involved.

“Lead-times in the industry are becoming critical. After Covid there were a huge number of projects that companies wanted to get off the ground and the best way to do that is to be able to get to market more quickly than conventionally would be the case. Aerospace as a sector really demonstrates the software’s advantages, because it has relatively low volumes, which means there is a greater dependence on shorter CAM programming to make parts quickly, particularly in product development. We have demonstrated CAM Assist for aerospace customers and produced a preliminary machining strategy for a part within 10 minutes which would have taken one of their own programmers around a week.”

Adding extra

And the benefits of CAM Assist go beyond just the reduction in time it takes to programme a component for machining. With a cutting strategy in place, companies can quickly provide a quote for a customer, give design for manufacture feedback and place the part into a production schedule, enabling programmers to use the time saved to programme more parts.

“We use it to check potential cycle times and what we quote to carry out a contract, so the benefits are not just the speed of programming, it’s also validating our process of producing parts,” Duke says.

It can also help fill the critical skills gap in CAM programming plaguing the engineering industry in general. The software can be used to upskill staff at companies more rapidly than traditional training pathways and smooth the route for newcomers to the industry.

“We need to make existing programmers more productive and find ways to make it easier for people to train and enter the industry. With CAM Assist we can get a junior programmer producing genuine parts within a week,” notes Saville.

Duke adds: “The figures for the high level of engineers who will be retiring in the next few years are very concerning. This software can help fill that skills gap. Although it’s not about taking jobs away from people it’s about enhancing the work that they already do and making them more productive.”

Proofed for the future

CAM Assist’s development comes at a timely moment for the aerospace industry with its need to develop fundamentally different power sources to meet environmental demands such as Net Zero.

“Traditionally the aerospace sector has been slow to adopt new technologies, particularly when it comes to flying parts,” Duke comments. “We have worked with one hydrogen power cell engine developer on its project. They are interested in using our software for the fundamental reason that it will enable them to get to market much quicker. And that is generally why companies want to get onboard because they can clearly see the benefits it could bring over their competitors.

“This really is a disruptive technology. When we were going through the investment rounds, a company sent us a CAD file for a part at very short notice and gave us the challenge of making it. Within 15 minutes we had created the cutter paths, given them a quote and sent the programme to the shopfloor with the CNC machine up and running within minutes.”

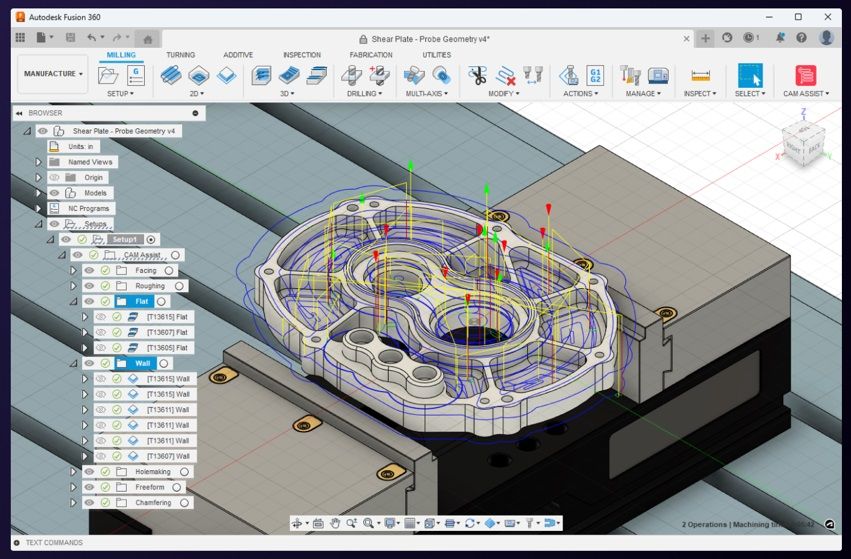

Currently CAM Assist is available as an add on for Autodesk Fusion 360, and coming soon to Mastercam, Solid Edge CAM and Siemens NX CAM Pro users with 3-axis machining capability. Although, CloudNC is developing versions capable of 5-axis (3+2) machining and for other CAM package providers.

“We realised it was better to add CAM Assist to an existing CAM package than to introduce a completely new one,” concludes Saville. “Users are already familiar with the software that they use, so if they disagree with the strategy CAM Assist produces, they can easily adapt or reverse it. It’s a much better way of delivering the benefits of CAM Assist and its value to companies and programmers.”

CAM Assist is available for download and support at: https://www.cloudnc.com/cam-assist