Skunk Works and Spirit unveil game-changing assembly technique

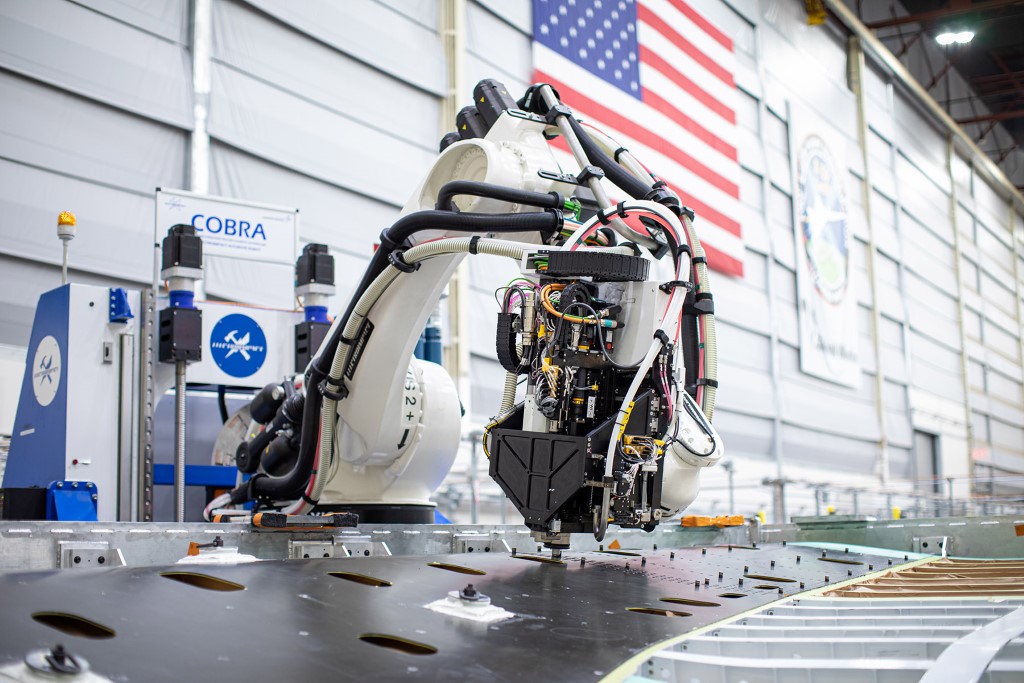

Using advanced digital manufacturing technology and robotic assembly, Lockheed Martin’s Skunk Works and Spirit AeroSystems have nearly doubled initial quality of assembly.

Called Polaris, the new demonstrator executes Full-Size Determinate Assembly (FSDA) and can be used to validate improvements in product development, from initial design to final assembly.

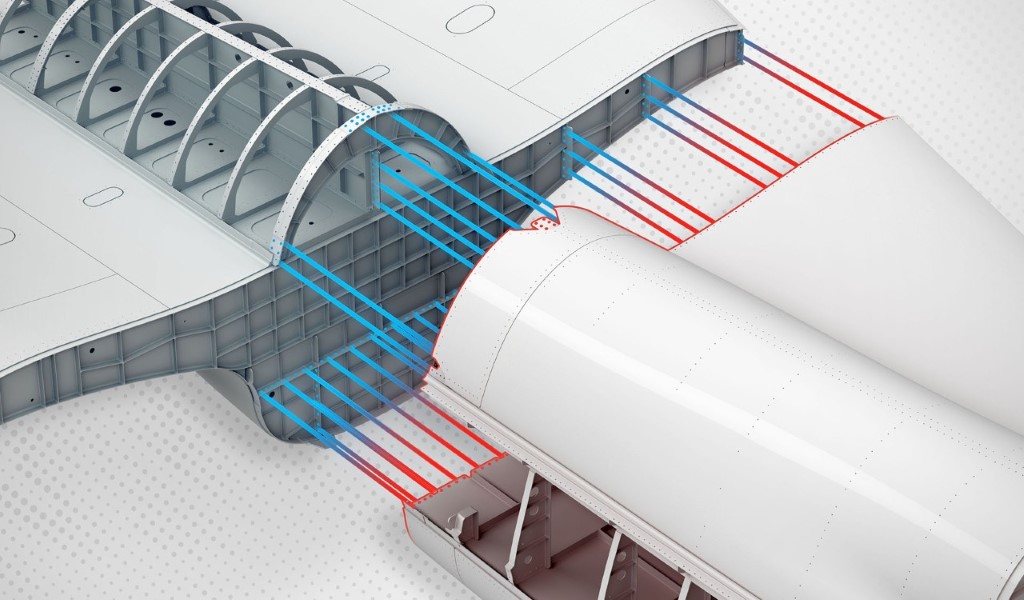

The programme has used the X-59 quiet supersonic aircraft design as a baseline to collect metrics and best practices to guide future transformation initiatives.

To do this, the Polaris team used an Integrated Digital Environment (IDE), a communication framework that moves information seamlessly from design through sustainment, on a separate, modified X-59 design suited for the digital environment.

Throughout the course of this project, the team has collaborated with Spirit in the same IDE, executing FSDA and ultimately robotically assembling a second article separate from the X-59 airframe.

FSDA uses precise digital engineering to produce precision parts that avoid the costly process of hand-fitting parts together during assembly.

Duane Hawkins, senior vice president at Spirit and president of its defence and space division, commented: “The IDE and its advanced production processes, including FSDA, will form the foundation of how future defence programmes are executed, and revolutionise the speed at which new products can be brought to market.”

Spirit integrated commercial best practices around digital design and manufacturing seamlessly into the Lockheed Martin IDE, enabling the collaborative development of production-ready solutions that build on the strengths of both the Spirit AeroSystems and Lockheed Martin teams.

This important accomplishment enables the programme and supplier team to share a single database for all artefacts, including CAD, systems engineering and programme planning data.

By working together in the same, real-time environment under a single source of truth, both the Polaris team and Spirit have the same access to design updates, task statuses and feedback. Polaris is taking collaboration with Spirit beyond emails and meetings, paving the way for more effective partnership.

“This reduced project execution cost and time by enabling parallel engineering development and operations planning, facilitating the team’s ability to clearly communicate and ensure consistency of requirements, and to identify integration challenges before parts and tools were ever released for fabrication,” Hawkins said.

This integration allows design and production optimization to occur simultaneously instead of as sequential discreet events, enabling production programs to progress down the learning curve prior to first-unit build.

As a result of the collaboration, advanced production processes were designed, planned, simulated, executed, and validated, leading to a 70% reduction in required assembly hours and a 95% increase in initial quality.

Polaris is one element of a larger multi-year investment called Project StarDrive. StarDrive is reengineering the culture, processes and tools needed to operate in a fully integrated digital work environment.