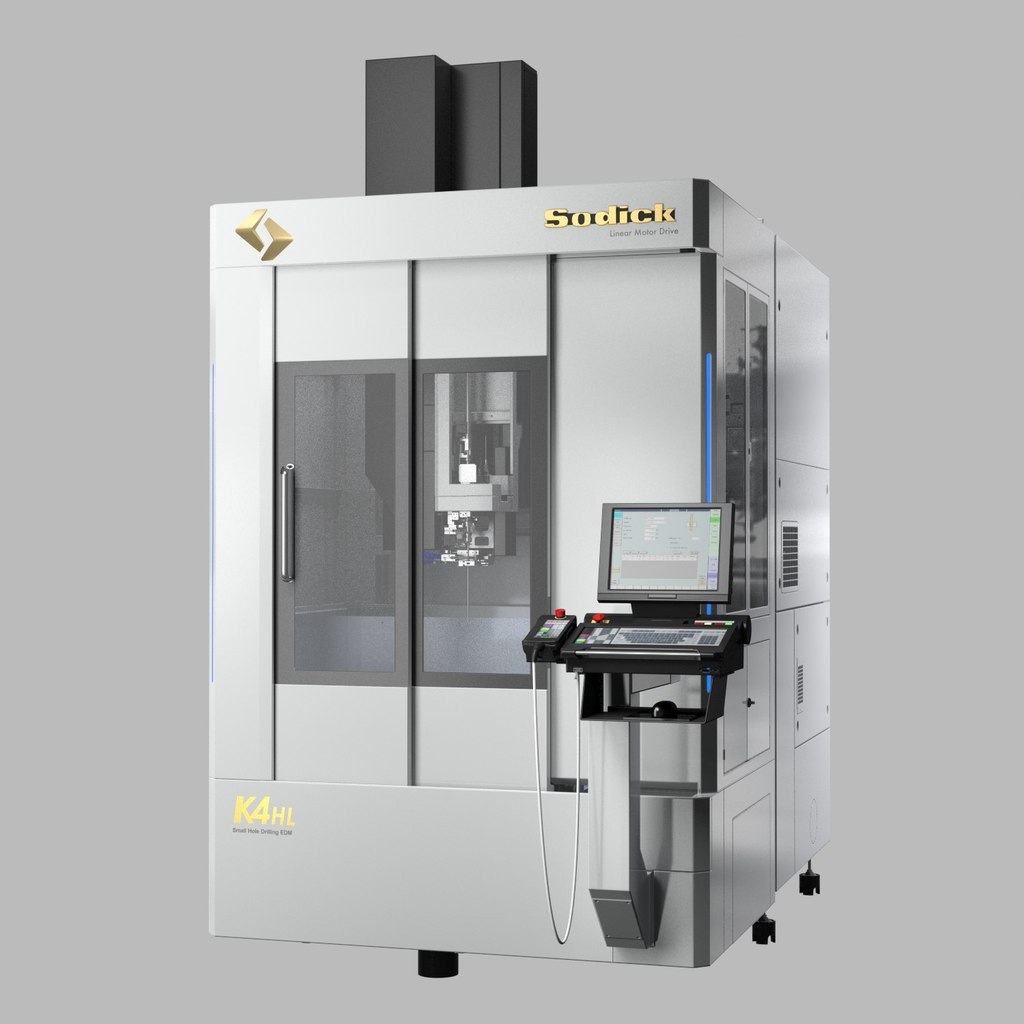

MACH debut for Sodick aero-focused hole drill machine

Shown for the first time in Europe, Sodick’s new 5-axis K4HL small hole drilling machine has been developed specifically to meet the needs of the aerospace and energy industries, for the high-speed drilling of the thousands of small, high-precision holes in exotic materials for aero-engines and other turbines.

MACH visitors will be given an overview of the capabilities of the machine through a series of working demonstrations on the stand 20-310, where the machine set up will incorporate a 2-axis worktable. After the show the K4HL will be relocated to Sodick HQ in Warwick, where it will be available for in-depth demonstrations.

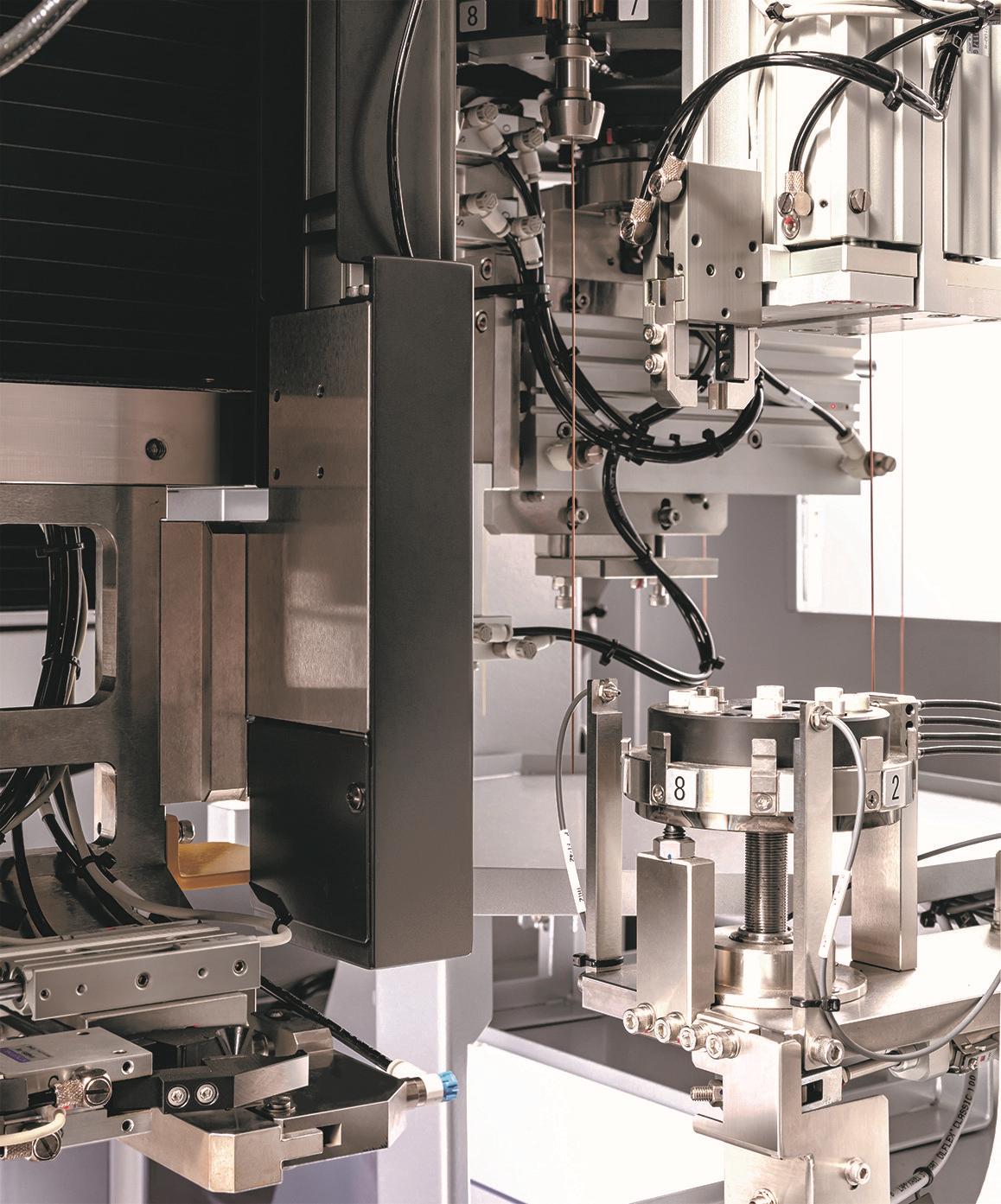

Facilities that make the K4HL particularly suited to the aerospace sector include: full 3-axis standard contouring or orbiting capability for the machining of small, high-precision diffuser holes in jet engine blades and vanes, a breakthrough detection function which eliminates back-striking in small chambers - reducing the potential for part scrapping when drilling unattended, and the SPK power supply which has been developed specifically for high quality small-hole drilling in difficult-to-burn materials such as titanium alloys/nickel alloys, iron/cemented carbide/copper/aluminium/brass.

Standard features include the automatic electrode feeder - for the unmanned drilling of multiple holes, automatic breakthrough detection and a diffuser-shaped hole drilling function. Additional options include an automatic electrode feed changer - which can increase stock pipe electrode capacity to 300+ (depending on diameter), an automatic tool changer, and a lower guide changer which supports the automatic electrode changer and the automatic electrode feeder changer, providing complete flexibility for parts with multiple holes of varying diameters.

The standard granite worktable can accommodate a workpiece of up to 740 x 640 x 500mm (W x D x H) and a maximum weight of 500kg. Electrode diameters are between 0.25 – 3.00mm with a maximum electrode length of 500mm. Excellent ergonomics are provided by an automatic front opening door with splash guard, ensuring exceptional operator access, while Sodick’s LN Professional software enables even inexperienced operators to run complex programs using an easy-to-understand graphic display.

And, last but not least, the K4HL machine is built to the same design as Sodick’s proven and successful AL40G and AL60G die-sinkers and, to ensure the highest level of accuracy, incorporates Sodick linear motor drives on the X, Y and Z axes.