Northrop Grumman accelerates hypersonic materials development

Northrop Grumman is accelerating development of high temperature materials through an automated carbon-carbon manufacturing process.

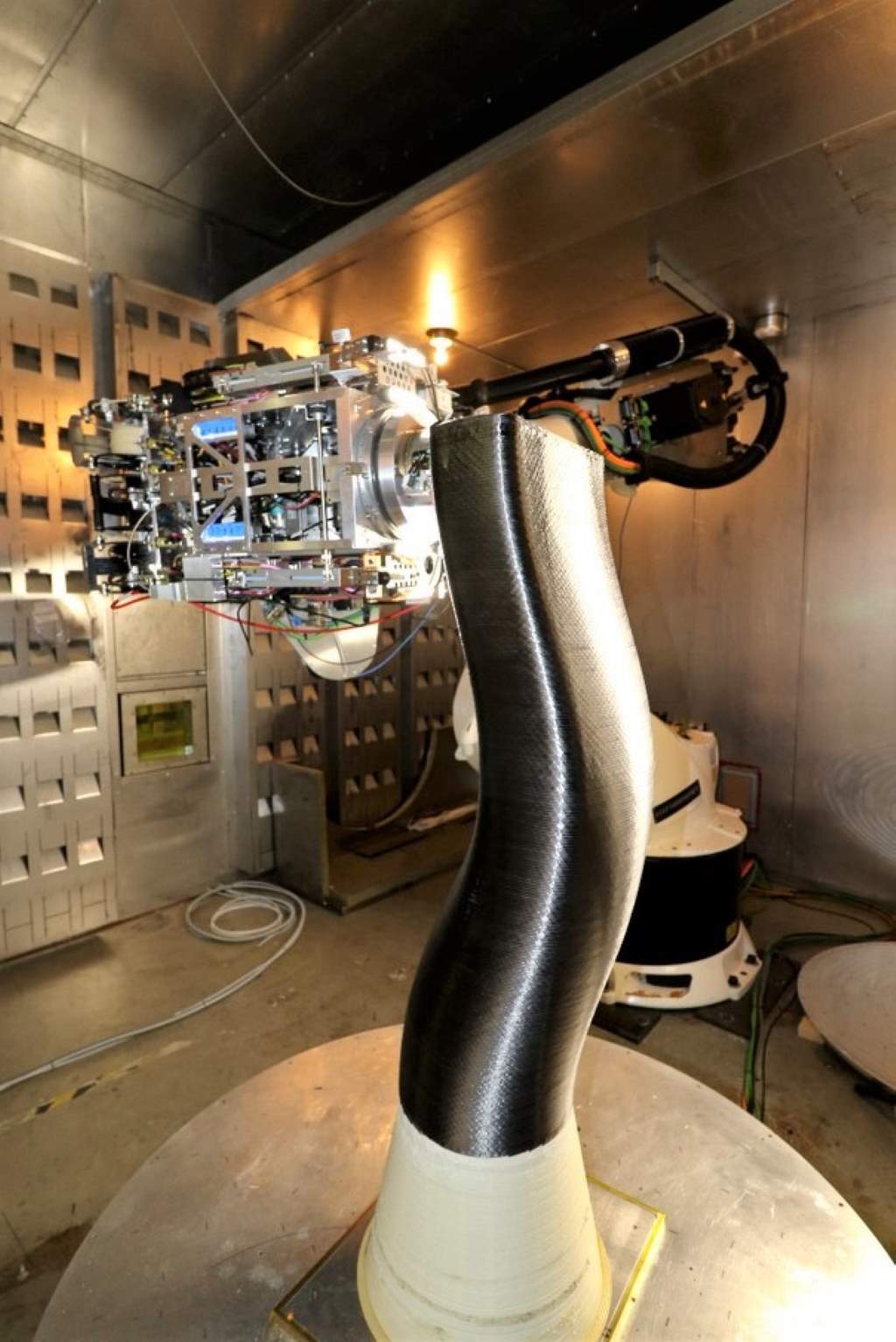

The company’s new advancement, called Scalable Composite Robotic Additive Manufacturing Carbon/Carbon (SCRAM C/C), will support new and emerging hypersonic weapons.

“We are pioneering a rapid fabrication process that does not require tooling to manufacturing aerospace-grade, continuous fibre integrated composite structures,” said Dan Olson, vice president and general manager of Weapon Systems for Northrop Grumman. “This manufacturing advancement will deliver capability to the field much faster than traditional methods, and ensures our warfighters have the latest technology and advanced weapons to counter both existing and future threats.”

SCRAM is an industrial, true 6-axis continuous fibre-reinforced 3D printer, which enables the fabrication of integrated composite structures. These structures then undergo a proprietary manufacturing process and turned into C/C to service the high temperature materials community where complex, near-net shapes are required.

Historically, C/C manufacturing techniques have been labour intensive. By introducing process automation, the manufacturing time and cost can be reduced by up to 50% over traditional methods delivering capability to the field faster. Process automation has also shown a measurable uptick in component quality and consistency.

Northrop Grumman is printing continuous fibre composites at a large scale. The company’s process does not require long-lead tooling and incorporates in-situ consolidation of the composite, which dramatically changes the cost paradigm to manufacture high temperature composites. The company has been awarded multiple patents on SCRAM technology.

Additive manufacturing has the potential to improve the agility of aerospace manufacturers where legacy casting and forging processes are often resource and time intensive.