Inspired by innovation

In a Q&A session, Soraluce’s UK sales manager, Asier Brunet explains how the company leads the future of the sector by creating value for its customers and setting new standards in milling, boring and turning.

In a Q&A session, Soraluce’s UK sales manager, Asier Brunet explains how the company leads the future of the sector by creating value for its customers and setting new standards in milling, boring and turning.

With 58 years of experience and inspired by innovation, Soraluce continues to evolve the machine tool sector thanks to its future-oriented manufacturing technologies. The company develops innovative solutions committed to the technological progress of its customers, responding to the most demanding machining challenges with efficiency and high levels of productivity, setting new standards.

Part of Danobatgroup, the machine tool division of Mondragon Corporation, Soraluce offers a wide range of milling machines, boring machines and vertical lathes, multitasking solutions and automated systems and lines, with professional advice on machining engineering. Innovation plays a key role in the company’s strategy and many of the developments that drive the machine tool industry forward are pioneering work by its products.

Q) What are the types of performance demands placed on your company by today’s aero landing gear customers?

Aerospace is, in general terms, a sector where the credibility of the suppliers is measured by their experience on each specific field, their machining knowledge and the reliability of their products. The wide range of options on Soraluce’s portfolio allows us to provide a custom solution to each customer. Additionally, we have the capacity to integrate custom-made solutions to make our machines even more flexible and user-friendly. A proper after-sales support is always a must, furthermore when talking about aerospace where Soraluce can grant the best service and support through our local delegations and partners in more than 45 countries.

Q) Is there a particular success customer success story you can discuss?

Soraluce helped Revima France, a leading independent MRO solution provider, specialising in APU, engineered parts and landing gear MRO for civil and military aircraft to improve the productivity of the landing gear maintenance process by reducing cycle time. We provided a complete solution for landing gear maintenance machining with: Automatic guided centring and reference process, avoiding any workpiece alignment; Any spatial position accessibility through stepless universal heads and angular heads; Complete turning and boring functionality in any position; Accessibility to machine internal cylinder housings; Soraluce custom cycles for centring and machining process.

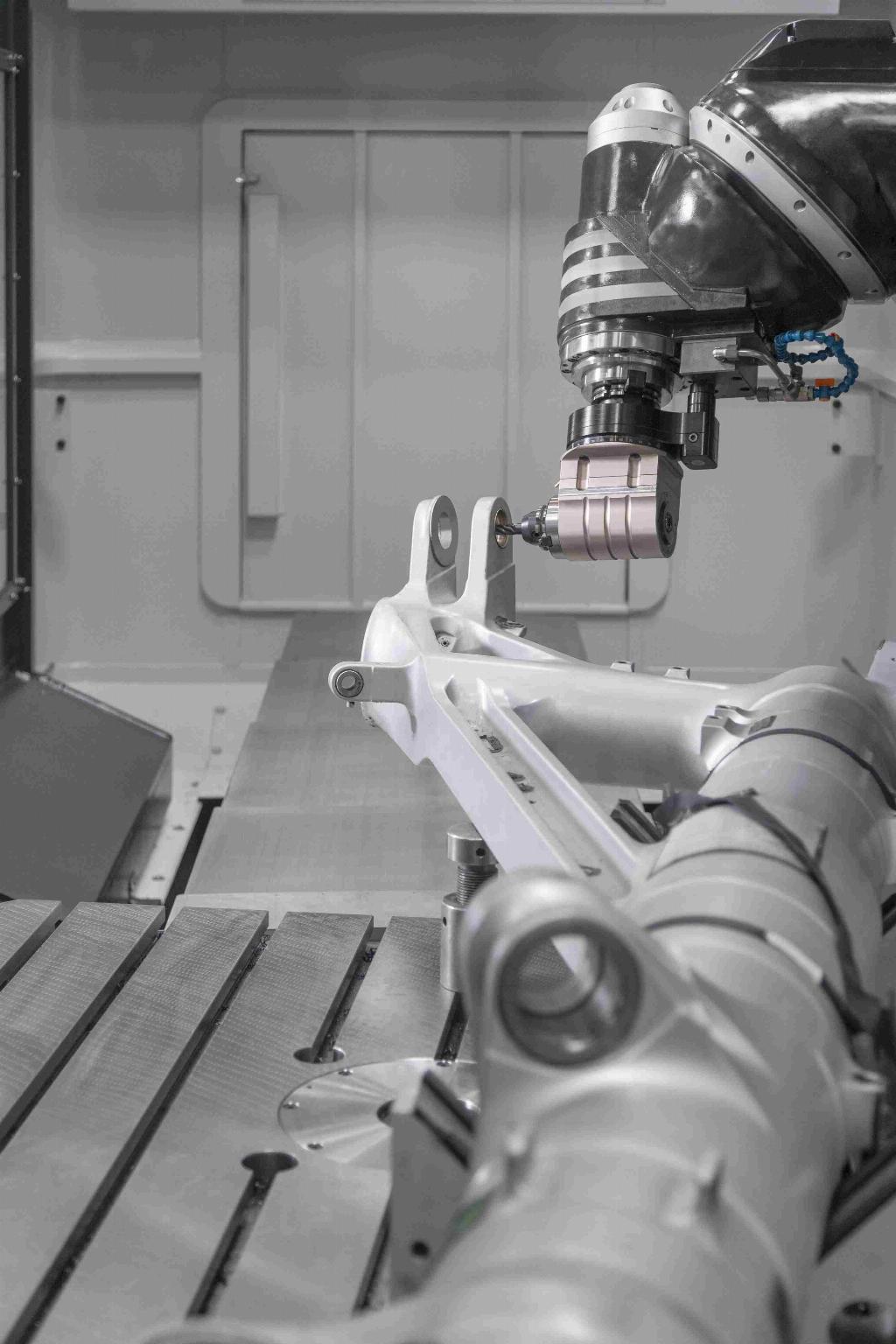

Q) Does your company provide any kinds of productivity benefits the use of robotics automation technology?

Apart from our ability on the machine tool design and fabrication, we have the skills and experience on the integration of robots or other kinds of automation to boost the productivity and flexibility of the whole system. Being a single supplier for all, the machine and other automated systems is also very welcome by our customers, as the communication relies on a single party.

Q) How much importance are you placing on Industry 4.0 and the advent of ‘smart tools’ and adaptive machining in general?

The new digital paradigm in manufacturing makes the interaction between machines, people and processes easier. Soraluce helps its customers to become more competitive by innovating in the field of industrial digitalisation, improving operational efficiency by connecting the machines to the cloud in order to enable a seamless production information flow and maximise the machines’ performance. The interconnection of the equipment and the possibility of obtaining and analysing data from machines, open up the path towards creating smart manufacturing environments.

Our Soraluce Data System platform is a machine data-driven analytics tool that extracts valuable insights from the machine-generated data and that monitors its status and condition to ensure that the running performance of the machining process is as high as possible. Soraluce Data System is a powerful tool to maximise uptime and manufacturing efficiency.

Using specific hardware and applying the latest Big Data and Cloud Computing technologies, Soraluce Data System collects and stores significant data from the CNC, PLC and sensors built into the machine and turns them into useful information. Soraluce Data System brings together a set of services based on machine monitoring and Big Data to analyse the machining process and machine behaviour. It enables users to connect to the system remotely and securely via mobile devices including laptops, smartphones and tablets, and to have access to all the relevant information of the machines, factory logistics systems or other machines in the production system taking customers to the realm of the smart factory. In addition, it allows the connection with other machines of the factory and also with different management software applications such as ERP, MES, etc.

Q) What do you feel are the most important assets of a company?

We have built a unique essence standing on four pillars. Four attributes that establish who we are. Four roads that take us in the direction of excellence and leadership: Leading technology - Leading product portfolio that includes new developments on medium and large size machines, multitasking solutions and automated systems. Advanced systems and Soraluce Software Factory offering the best machine performance; Engineering knowledge - The best process for specific application, ensuring the optimal configuration of the solution for each specific need; Digital dimension - a fully digitised company offering the most advanced services such as condition-based maintenance, advanced digital services and machines connected and interconnected at all levels; Sustainable development - Our company works towards integrity, liable company environments, less polluting machines, responsibility for people and towards society.

Q) What differentiates your company’s machine tool products from the competition - why should a customer use you over your nearest rival?

Innovation in Soraluce moves beyond mere ideas; it becomes real and tangible in products and projects that set new standards in milling, boring and turning. Soraluce demonstrates technological leadership, developing products and services to ensure that our customers perform even better. Soraluce develops innovative solutions committed to customers’ technological progress, responding to the most demanding machining challenges efficiently and with high levels of productivity. It takes technology to the limits through constant evolution, to supply reliable solutions and a wide range of added value services.

Soraluce is committed to active listening, asking and analysing what customers need from their technology partner. We’re thinking, feeling and acting the way our customers want us to. #MadeForYOU is our relationship with our customers. It is actively participating by responding to their unique characteristics as a comprehensive, technologically-advanced machinery partner, making the ‘Intelligent Machine’ a reality, while providing high-added-value services and solutions, offering expert advice in machining engineering.

Greater production rates, higher accuracy, improved efficiency, enhanced performance, user-friendliness, ergonomics, safety and cost effectiveness – all while reducing cycle times, downtime, consumption and emissions. This is the sort of progress that makes sense for Soraluce.

Q) What developments do you see happening in the design of landing gear systems?

We consider the prospects for the future are good. Of course, the R&D work doesn’t stop and we will see many improvements in the following years. According to the experts and mainly in the studies of Oliver Wyman ‘Global Fleet & MRO Market Forecast 2020-2030’, the total fleet will be around 39,000 planes and the estimation is to manufacture 2,100 new planes per year. At the same time will be changes in the propulsion (electrical) and new materials.