The weight is over!

According to Alvant, its Aluminium Matrix Composites offer significant landing gear weight reductions – among other areas, allowing manufactures to meet the challenge of reduced weight.

Aerospace manufacturers are currently looking for ways to reduce weight without compromising on structural integrity, as well as increasing product capabilities and performance, while simultaneously meeting ambitious goals for sustainability, emissions and fuel efficiency.

One such example is a metal matrix composite from the UK. Composite manufacturer, Alvant recently partnered with Safran Landing Systems, on a £28 million, two-year project, which aims to reduce landing gear components weight by as much as 30%.

The project, titled ‘Large Landing Gear of the Future’, will look to challenge the traditional materials used in the design and manufacture of landing gear assemblies, which are currently stronger and heavier than necessary. Accounting for approximately 3% of the total aircraft weight, the current landing gear has a corresponding negative effect on fuel consumption.

Entering the matrix

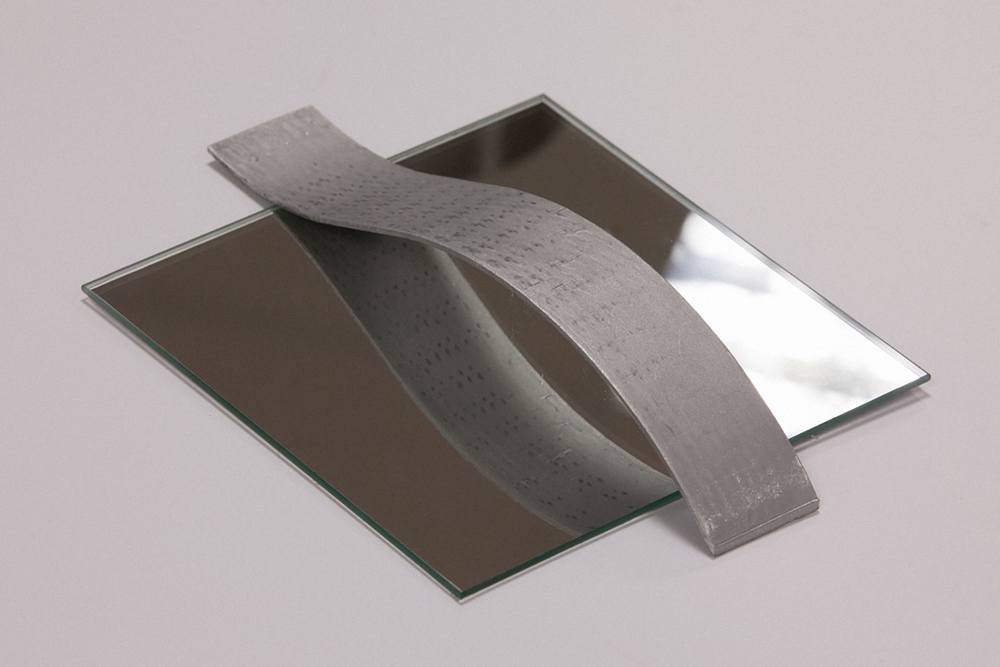

Alvant’s Aluminium Matrix Composites (AMCs) are an advanced class of composite materials, in which the aluminium is reinforced with a secondary high-performance material; typically, a long fibre, short fibre or particulate. Available in multiple variants, AMCs are used to engineer durable lightweight components for harsh environments, as well as for use in applications where conventional metals are expected to approach or exceed their performance limits. Desired properties, such as stiffness, strength and density properties can be tailored through particle-reinforcement with continuous fibre-reinforcement (CFR) preferred for applications where higher performance is needed.

Compared to unreinforced metals, AMCs can have higher strength, greater stiffness, lower weight, superior wear resistance, lower coefficients of thermal expansion and superior electrical conductivity – as well as offering multiple advantages over polymer fibre-reinforced materials, such as carbon composites. These include higher transverse strength and stiffness, a higher thermal operating range, better wear resistance, superior damage tolerance, easier repairability and a greater opportunity to recycle. AMCs can offer superior longitudinal strength to that of steel, at one-third of the weight. For harsh environments AMCs can have superior fatigue strength to steels.

Alvant’s contribution to the landing gear project is its AlXal product, a continuous fibre-based AMC. With the help of a £513,000 grant from Innovate UK, Alvant is designing, manufacturing and testing an AlXal brake rod with an expected 30% weight reduction over an equivalent titanium component, while maintaining a comparable strength to steel - reducing fuel burn and noise, while also improving reliability and lowering costs.

“The project aims to make use of new materials and manufacturing methods to develop and demonstrate technologies that will reduce landing gear weight, fuel burn and noise, at the same time as improving reliability and lowering maintenance, repair and operating costs,” says Richard Thompson, commercial director at Alvant.

“A key objective of the Large Landing Gear project is to test and demonstrate as many technology advances as possible,” adds Thompson. “Alvant’s AMCs are a sustainable solution that enhance product capabilities. This landing gear component is just one of the many ways in which AMCs can help aerospace firms retain strength while reducing weight.”

According to Alvant, AMCs offer significant weight reductions compared to legacy materials, allowing manufactures to meet the challenge of reduced weight and fuel burn while maintaining reliability and lowering whole-life ownership costs - and may be a lifeline for industries that need to meet ever stringent market and legislative demands.

In order to manage cost and complexity, components do not need to be manufactured entirely from aluminium matrix composite. Components can be reinforced locally in a method known as hybrid-AMC avoiding regions of low stress, where enhanced mechanical properties are not required and providing performance precisely where it’s needed, using AMC inserts applied to the larger aluminium component. This limits the fibre content, simplifies the AMC insert geometry, and reduces costs whilst increasing the performance and capability of the component.

Where safety and reliability are essential, AMCs could find use applications in high-pressure seals, aircraft landing gear and seats. Due to their capability to withstand extreme temperatures, AMCs are also suitable for components in high-voltage battery systems, UAVs and defence applications.